Method for degrading pigment wastewater by utilizing iron-based amorphous alloy activated persulfate

An iron-based amorphous alloy, a technology for activating persulfate, applied in chemical instruments and methods, iron compounds, oxidized water/sewage treatment, etc., can solve the effect of oxidative degradation of dye wastewater, low sulfate radical efficiency, Nano-iron tetroxide is easy to agglomerate and other problems, to achieve the effect of reducing water treatment costs, strong forming ability, and simplifying process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

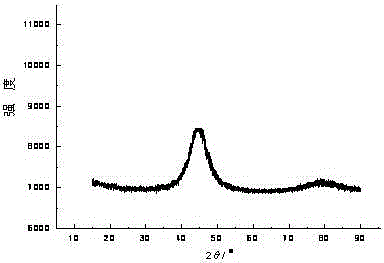

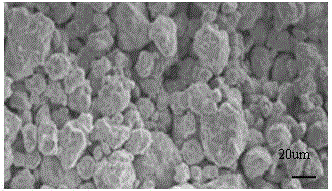

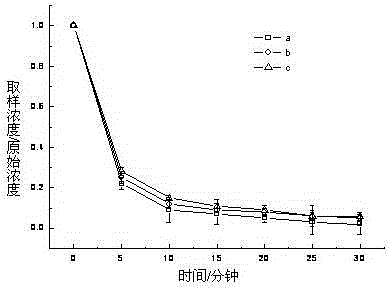

Embodiment 1

[0023] 1. Preparation of Fe-based amorphous alloy powder dispersion: Prepare Fe by mechanical alloying technology 78 Si 9 B 13 Amorphous alloy powder, all equipment is a star ball mill. (1) The elemental raw materials used in the test are powders of Fe, Si and B, the particle size is 200 mesh, and the purity is not less than 99.99% (mass percentage). Stainless steel was selected as the ball milling medium. Three kinds of stainless steel balls were used in the test, namely 800 stainless steel balls with a radius of 2 mm, 500 stainless steel balls with a radius of 6 mm, and 10 stainless steel balls with a radius of 8 mm. (2) Put the accurately weighed Fe, Si and B powders into the ball mill pot, then put the above stainless steel balls into the ball mill pot, and seal the ball mill pot. Then use a vacuum pump to evacuate and fill it with high-purity argon as a protective gas. Repeat the above steps for 6 times to ensure the purity of the argon in the final ball mill filling. ...

Embodiment 2

[0027] 1. Preparation of Fe-based amorphous alloy powder dispersion: Prepare Fe by mechanical alloying technology 78 Si 9 B 13Amorphous alloy powder, all equipment is a star ball mill. (1) The elemental raw materials used in the test are powders of Fe, Si and B, the particle size is 200 mesh, and the purity is not less than 99.99% (mass percentage). Stainless steel was selected as the ball milling medium. Three kinds of stainless steel balls were used in the test, namely 800 stainless steel balls with a radius of 2 mm, 500 stainless steel balls with a radius of 6 mm, and 10 stainless steel balls with a radius of 8 mm. (2) Put the accurately weighed Fe, Si and B powders into the ball mill pot, then put the above stainless steel balls into the ball mill pot, and seal the ball mill pot. Then use a vacuum pump to evacuate and fill it with high-purity argon as a protective gas. Repeat the above steps for 6 times to ensure the purity of the argon in the final ball mill filling. F...

Embodiment 3

[0031] 1. Preparation of Fe-based amorphous alloy powder dispersion: Prepare Fe by mechanical alloying technology 78 Si 9 B 13 Amorphous alloy powder, all equipment is a star ball mill. (1) The elemental raw materials used in the test are powders of Fe, Si and B, the particle size is 200 mesh, and the purity is not less than 99.99% (mass percentage). Stainless steel was selected as the ball milling medium. Three kinds of stainless steel balls were used in the test, namely 800 stainless steel balls with a radius of 2 mm, 500 stainless steel balls with a radius of 6 mm, and 10 stainless steel balls with a radius of 8 mm. (2) Put the accurately weighed Fe, Si and B powders into the ball mill pot, then put the above stainless steel balls into the ball mill pot, and seal the ball mill pot. Then use a vacuum pump to evacuate and fill it with high-purity argon as a protective gas. Repeat the above steps for 6 times to ensure the purity of the argon in the final ball mill filling. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com