Method and device for recycling ethanol in production of hexanitrostilbene

A technology of hexanitrobibenzyl and ethanol, which is applied in the field of ethanol in the production of hexanitrobibenzyl recovered by pervaporation method, which can solve the problem of easy introduction of the third component into the product, large amount of the third component, and large equipment footprint and other problems, to achieve the effect of improving energy utilization, saving reagent consumption, and reducing equipment footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

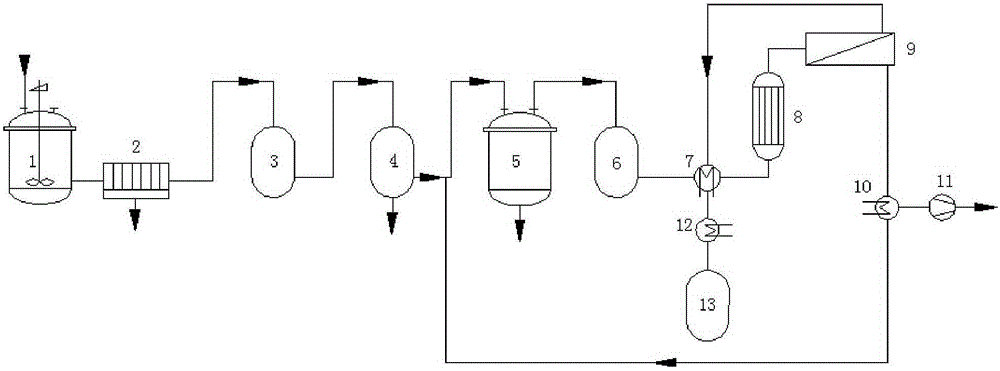

[0040] The method of ethanol recovery in the production of hexanitrobibenzyl, the equipment used is such as figure 1 As shown, the operation process includes the following steps: the mother liquor from the hexanitrobibenzyl oxidative coupling reaction section is firstly filtered in the filter press 2, the filtrate then enters the feed liquid tank 3, and finally enters the crystallization tank 4 for crystallization, and the upper mother liquor (The water content is about 20wt%) is sent to the distillation pot 5 for concentration, and the distilled ethanol is collected in the intermediate tank 6. The volume of the mother liquor is reduced to about 25% during the distillation process, and the water content of the intermediate tank 6 is an ethanol solution of 15wt%. The material liquid in the intermediate tank 6 is delivered to the preheater 7 with a controlled flow rate of 900kg / h. The material liquid is preheated to 80°C by the product steam, and then it is heated in the evaporato...

Embodiment 2

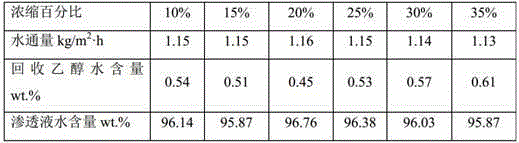

[0046] The method of ethanol recovery in the production of hexanitrobibenzyl, the equipment used is such as figure 1 As shown, the operation process includes the following steps: the mother liquor obtained from the hexanitrobibenzyl oxidative coupling reaction section is firstly filtered in the filter press 2, the filtrate then enters the feed liquid tank 3, and finally enters the crystallization tank 4 for crystallization, the upper mother liquor (The water content is about 20wt%) is sent to the distillation pot 5 for concentration, and the distilled ethanol is collected in the intermediate tank 6. During the distillation process, the volume of the concentrated liquid is reduced to about 10%, 15%, 20%, 25%, 30%, and 35% respectively. (Mass percentage), an ethanol solution with a water content of 12 wt% in the intermediate tank 6. The flow rate in the intermediate tank 6 is controlled to 1200kg / h and sent to the preheater 7, the material liquid is preheated to 75°C by the produ...

Embodiment 3

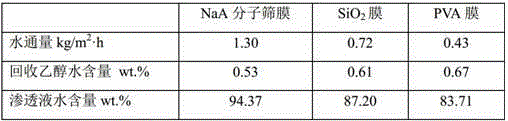

[0052] The method of ethanol recovery in the production of hexanitrobibenzyl, the equipment used is such as figure 1 As shown, the operation process includes the following steps: the mother liquor obtained from the hexanitrobibenzyl oxidative coupling reaction section is firstly filtered in the filter press 2, the filtrate then enters the feed liquid tank 3, and finally enters the crystallization tank 4 for crystallization, the upper mother liquor (The water content is about 15wt%) is sent to the distillation pot 5 for concentration, and the distilled ethanol is collected in the intermediate tank 6. The intermediate tank 6 contains an ethanol solution with a water content of 10wt%. The ethanol in the intermediate tank 6 is transferred to the preheater 7 with a controlled flow rate of 1000kg / h. The material liquid is preheated to 85°C by the product steam, and then it is heated in the evaporator 8. The material liquid is heated to 110°C to steam The form enters into 15 NaA molec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com