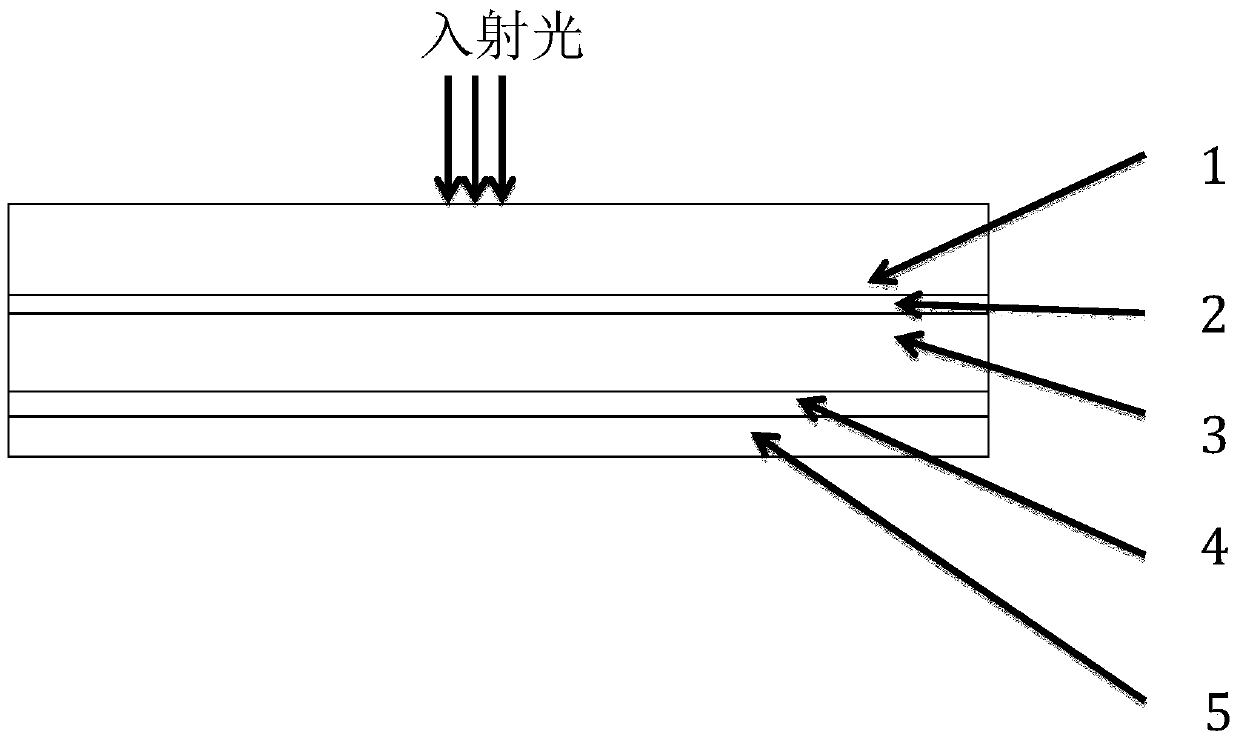

Thin film crystalline silicon perovskite heterojunction solar cell and preparation method thereof

A solar cell and perovskite technology, applied in circuits, electrical components, electrical solid devices, etc., can solve the problems of insufficient stability, poor photoelectric conversion performance of perovskite solar cells, and large usage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] The first step is to prepare a P-type thin film crystalline silicon hole transport layer on a transparent conductive substrate:

[0061] Use a P-type single crystal silicon wafer coated with a layer of corrosion-resistant metal on the back as the anode, and use platinum as the cathode. anodic oxidation with an electric current, corrode the P-type single crystal silicon wafer by electrochemical method, and form a porous silicon structure on the surface of the single crystal silicon wafer, and then form the single crystal silicon wafer with the porous silicon structure in H 2 Annealing at 200°C to 550°C in the atmosphere, during the annealing process, the holes in the small porosity layer on the surface of the single crystal silicon wafer will gradually close to form a quasi-single crystal layer as a template for epitaxial devices. The P-type thin film crystalline silicon film is epitaxially formed on the layer, and the formed P-type crystalline silicon film is transferre...

Embodiment 2

[0081] The first step is to prepare a P-type thin film crystalline silicon hole transport layer on a transparent conductive substrate:

[0082] With a P-type single crystal silicon wafer coated with a layer of corrosion-resistant metal on the back as the anode and platinum as the cathode, in a hydrofluoric acid ethanol solution with a volume ratio of hydrofluoric acid: absolute ethanol = 1:1, the size is 4.5 The current of A is anodized, and the P-type single crystal silicon wafer is corroded by an electrochemical method to form a porous silicon structure on the surface of the single crystal silicon wafer, and then the single crystal silicon wafer with a porous silicon structure is formed in H 2 Annealing at 200°C to 550°C in the atmosphere, during the annealing process, the holes in the small porosity layer on the surface of the single crystal silicon wafer will gradually close to form a quasi-single crystal layer as a template for epitaxial devices. The P-type thin film crys...

Embodiment 3

[0102] The first step is to prepare a P-type thin film crystalline silicon hole transport layer on a transparent conductive substrate:

[0103] With a P-type single crystal silicon wafer coated with a layer of corrosion-resistant metal on the back as the anode, and platinum as the cathode, in a hydrofluoric acid ethanol solution with a volume ratio of hydrofluoric acid: absolute ethanol = 1:1, a size of 7.5 The current of A is anodized, and the P-type single crystal silicon wafer is corroded by an electrochemical method to form a porous silicon structure on the surface of the single crystal silicon wafer, and then the single crystal silicon wafer with a porous silicon structure is formed in H 2 Annealing at 200°C to 550°C in the atmosphere, during the annealing process, the holes in the small porosity layer on the surface of the single crystal silicon wafer will gradually close to form a quasi-single crystal layer as a template for epitaxial devices. The P-type thin film cryst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com