Titanium lithium silicate anode material for lithium-ion battery and preparation method and application

A lithium-ion battery, lithium titanium silicate technology, applied in battery electrodes, secondary batteries, circuits, etc., to achieve good application prospects, avoid poor cycle performance, and excellent cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1: Add 3.4g tetra-n-butyl titanate (TBOT) and 2.1g tetraethyl orthosilicate to 200mL ethanol solution, stir well and add 10mL of aqueous solution containing 0.84g lithium hydroxide monohydrate and 0.35g sucrose , stirred vigorously to volatilize the obtained solution to dryness, the obtained white solid precursor was placed in a muffle furnace, calcined at 300 ° C for 4 hours, and then placed in a tube furnace, calcined at 900 ° C for 24 hours under the protection of argon, that is, Carbon coated lithium titanium silicate.

[0033] The above prepared negative electrode material powder and carbon black and a concentration of 9% polyvinylidene fluoride N-methyl-2-pyrrolidone solution are fully ground into a uniform slurry viscous liquid, wherein carbon black accounts for 10% of the weight of the negative electrode material powder, Polyvinylidene fluoride accounts for 10% of the weight of the negative electrode material powder. Then it is coated on the copper foil...

Embodiment 2

[0034] Example 2: Put 6g of nano-silica (about 10nm), 8g of nano-titanium dioxide (about 8nm), 14g of lithium nitrate and 1.74g of expanded graphite, put them in a ball mill jar after simple mixing, and ball mill for 8 hours. In a tube furnace, calcined at 900° C. for 24 hours under the protection of argon to obtain nanoscale lithium titanium silicate coated with expanded graphite carbon.

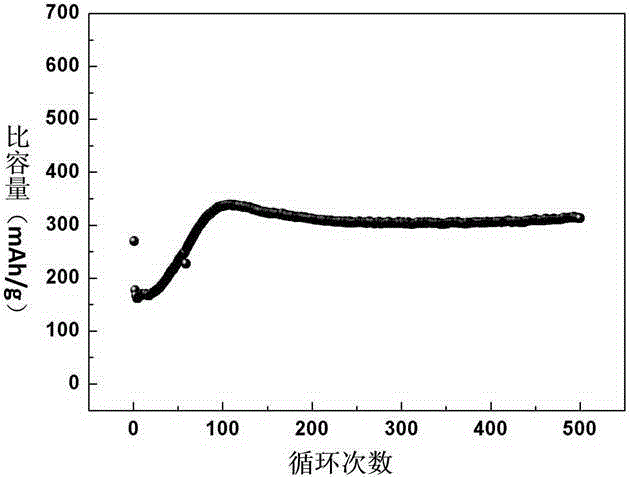

[0035] The negative electrode material prepared above was processed and tested according to the method in Example 1. Compared with the battery in Example 1, the battery performance was slightly lowered in the capacity of high-current charging / discharging, but the long-term cycle performance was slightly improved. .

Embodiment 3

[0036] Example 3: 3.4 g of tetra-n-butyl titanate (TBOT) and 2.1 g of tetraethyl orthosilicate (TEOS) were added to 200 mL of ethanol solution, and evaporated to dryness. The obtained white solid precursor was placed in a muffle furnace, calcined at 300°C for 4 hours, and then calcined at 800°C for 4 hours under an argon / toluene atmosphere. The obtained black solid powder was mixed with 0.84g of lithium salt, and calcined at 900°C for 24 hours to obtain Nano-lithium titanium silicate coated by chemical vapor deposition.

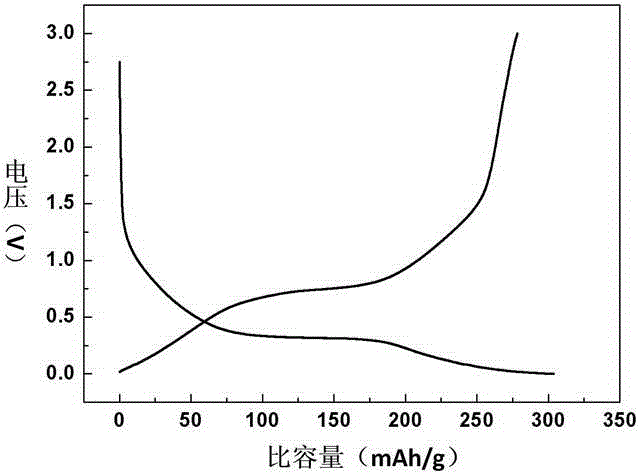

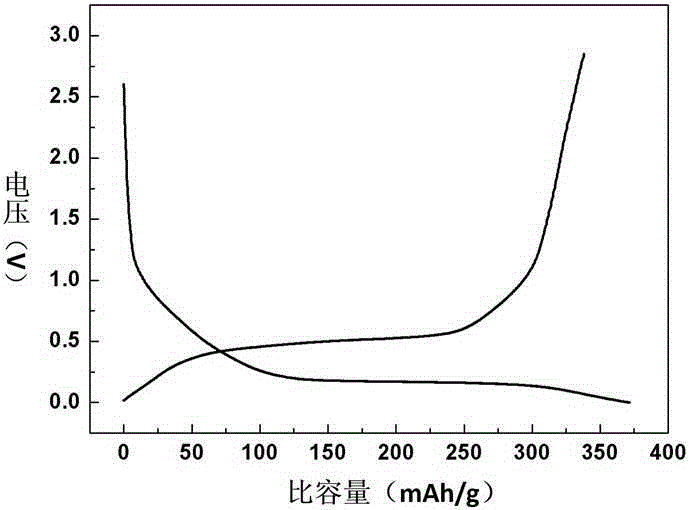

[0037] The negative electrode material obtained above was processed and tested according to the method in Example 1, and the first-cycle capacity of the obtained battery was 290mAh / g at a current of 30mA / g, and the capacity was greater than that of uncoated titanium silicate at a relatively high current. The capacity of lithium is slightly higher than the result obtained in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com