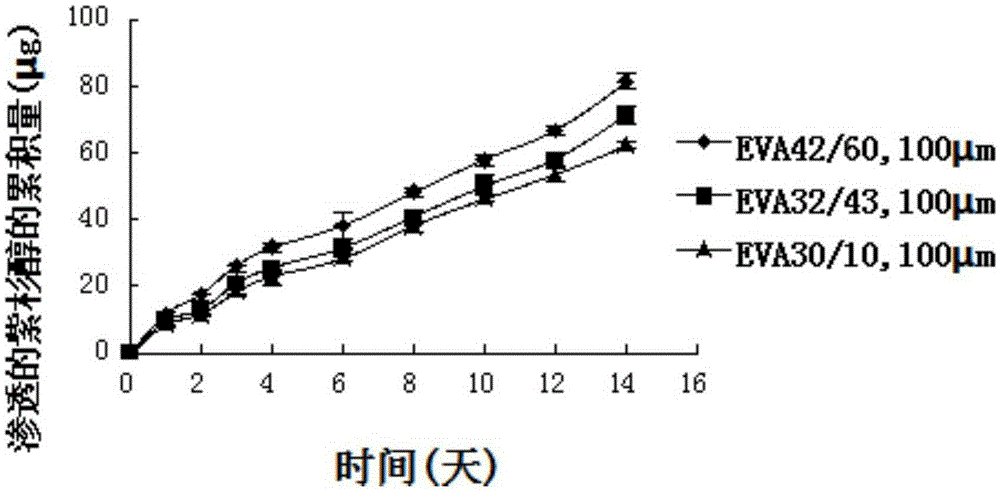

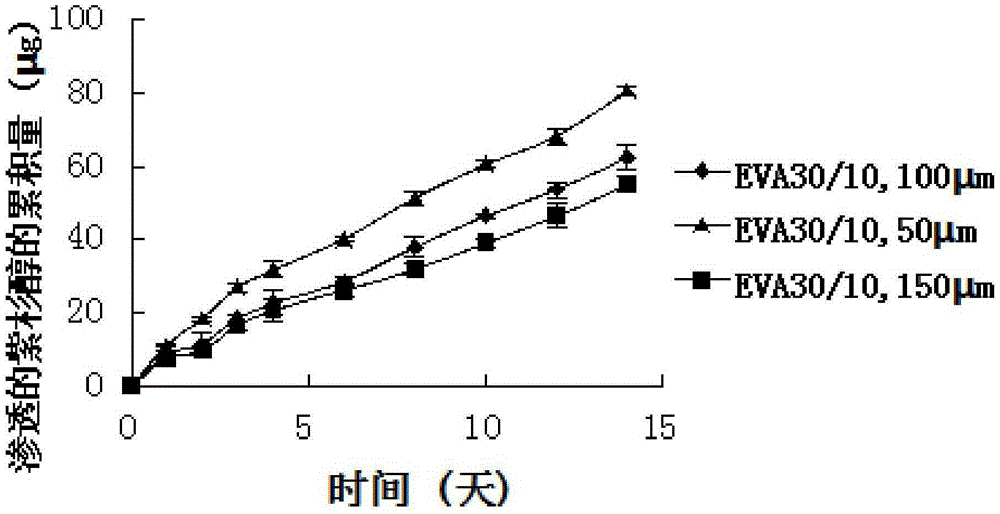

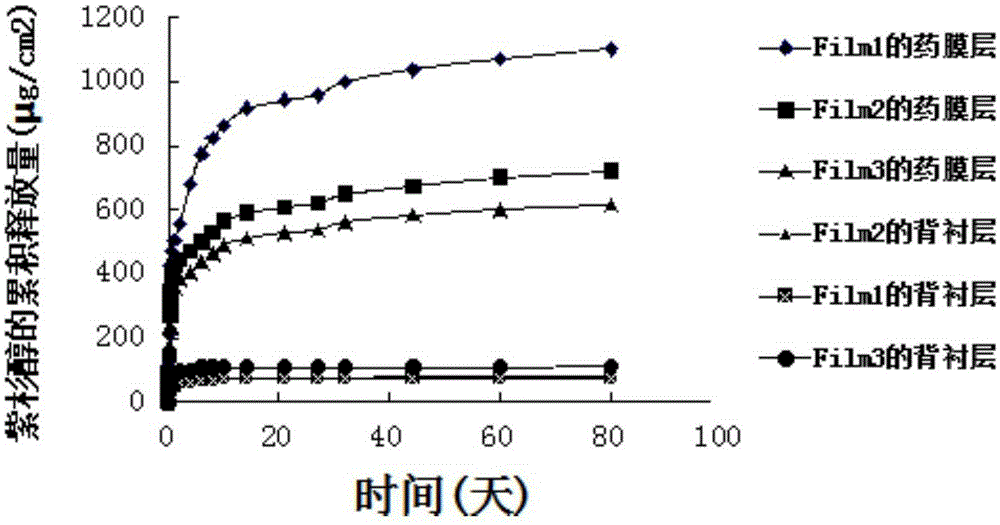

Paclitaxel-loaded ethylene-vinyl acetate esophageal stent and preparation method thereof

A vinyl acetate esophagus, vinyl acetate technology, applied in the field of medical devices, can solve the problems of ineffective regulation and control of drug release, slow release of 5-fluorouracil, lack of basis for selection of backing layers, etc. The effect of simple and easy measurement method and preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment relates to the preparation of the backing layer, and the specific operations are as follows:

[0041] Weigh about 4.0g of EVA and dissolve it in 30ml of dichloromethane solution, place it in a water-bath shaker at 37°C overnight, then take it out, and vortex for about 10min until the EVA is completely dissolved to obtain a backing layer solution.

[0042] Put a braided 3.5cm long, 0.9cm in diameter Ni-Ti alloy bare metal stent with a diameter of 1.1cm in expansion ports at both ends on a glass rod with a diameter of 0.9cm, and slowly immerse in the prepared backing layer polymer solution for 2s~ 10s, take it out and volatilize in the fume hood for 24 hours, take it off the glass rod for use, and get the metal bracket covered with the backing layer.

Embodiment 2

[0044] The present embodiment relates to the preparation of drug film, concrete operation is as follows:

[0045] According to the formula that the ratio of polymer material to paclitaxel is 1:1, feed and mix with the hacker machine. The specific operation steps are: raise the temperature of the feeding chamber of the hacker KAAKEMiniLabII to 85°C, add EVA, start the hacker machine, and rotate to clean Feeding chamber. The above steps can be repeated many times to ensure that the feeding chamber is clean. After fully cleaning the Hack machine, add the prescription ingredients corresponding to the prescription numbers in the table, and mix for 30 minutes. After mixing, put a polyester film of a certain size under the feeding chamber, then open the feeding chamber, and scrape the mixture while it is hot. .

Embodiment 3

[0047] This embodiment relates to the pressing and orientation of the drug film, and the specific operations are as follows:

[0048] (1) The carrier material is EVA42 / 60, and the drug film with a drug loading capacity of 50% is pressed under a film press at 100°C to about 340 μm and 320 μm, with an initial length of 2.5 cm, and at a constant temperature of 80°C, at a speed of 2.5min / r Stretch on the orientation machine, stretch orientation 2.4 times and 2.35 times, about 6.0cm and 5.8cm long. When it reaches about 180 μm, cool at room temperature for 30 minutes, remove it from the orientation machine, and cut it for later use.

[0049] (2) The carrier material is EVA32 / 43, and the drug film with a drug loading capacity of 50% is pressed under a film press at 100°C for about 1.5 hours to about 350 μm, with an initial length of 2.5 cm. Cut into two parts, one part was pressed at 100°C for about 2 hours to reach a thickness of about 180 μm, cooled at room temperature for 30 min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com