Method and apparatus for continuous conversion production of sodium nitrate

A sodium nitrate, pre-conversion technology, applied in chemical instruments and methods, alkali metal nitrates, inorganic chemistry, etc., can solve the problems of long conversion time, equipment susceptible to high temperature acid corrosion, high investment cost, and reduce pumps and pipelines. and other components, accelerate the conversion reaction speed, and reduce the effect of environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

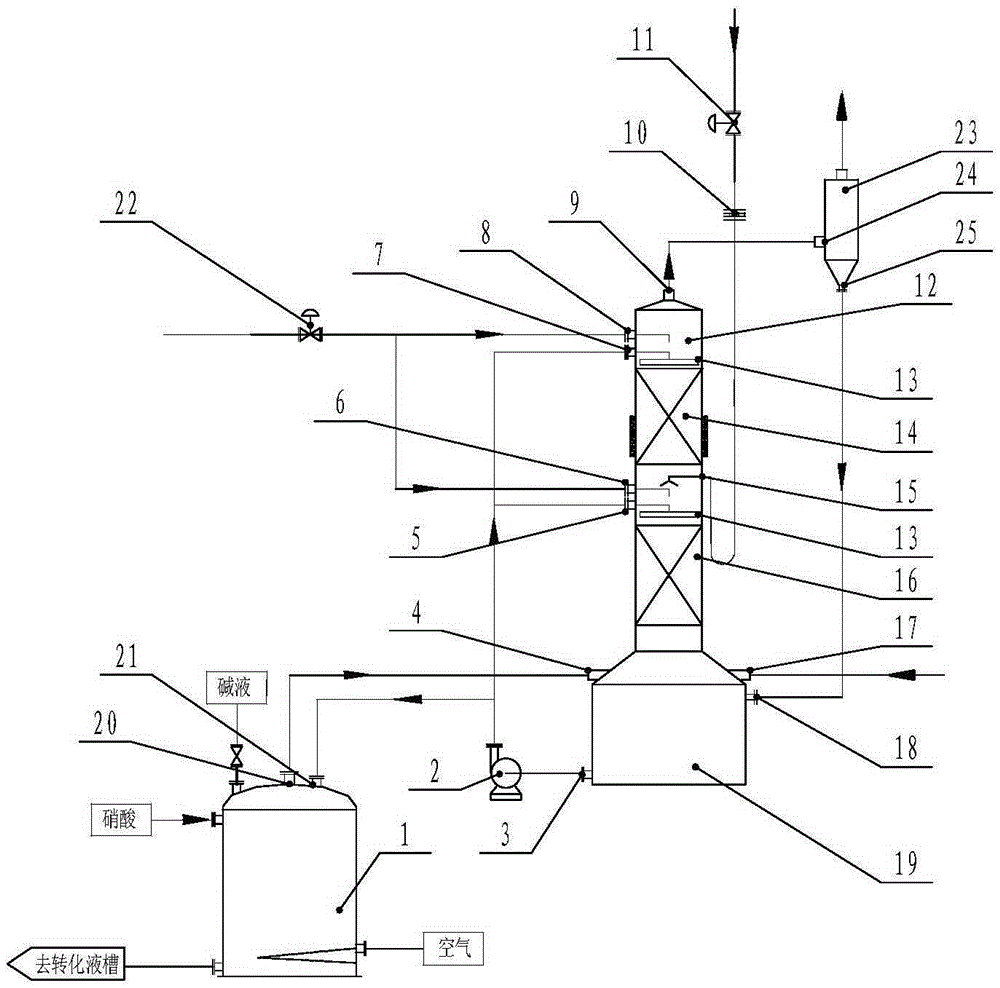

[0038] A kind of equipment that realizes the method for producing sodium nitrate by continuous conversion, comprising a conversion absorption tower 12, a converter 1 and an absorption separator 23, the conversion absorption tower 12 is a packed tower, including an upper pre-reforming section 14, a middle conversion absorption section 16 and a lower liquid storage tank 19; the pre-reforming section 14 of the conversion absorption tower 12 is provided with an upper mother liquid inlet 8 and an upper circulating liquid inlet 7, and the middle conversion absorption section 16 is provided with a middle mother liquid inlet 6 and a middle circulating liquid inlet 5 And dilute nitric acid inlet 15, lower liquid storage tank 19 is provided with conversion liquid outlet 3, tail gas inlet 4, mixed acid tail gas inlet 17, condensate inlet 18; Described conversion liquid outlet 3 connects the conversion liquid inlet 21 of converter 1 and the upper The circulating liquid inlet 7, the central...

Embodiment 2

[0040] 1, a kind of method of continuous conversion production sodium nitrate, comprises the following steps:

[0041] (1) Pre-transformation stage:

[0042] a. Turn on the conversion circulating pump 2, adjust the circulating liquid to the middle circulating liquid inlet 5 and the upper circulating liquid inlet 7 of the conversion absorption tower 12 through the valve adjustment, and evenly distribute the liquid through the distributor 13;

[0043]B, the mixed mother liquor of sodium nitrite and sodium nitrate is sent into the middle part mother liquor inlet 6 and the upper mother liquor inlet 8 of conversion absorption tower 12 respectively through mother liquor flow regulating valve 22, and is evenly distributed through distributor 13;

[0044] c. In the upper pre-reforming section 14, mix the mother liquor and circulating liquid to absorb the tail gas from the bottom of the conversion absorption tower 12, and carry out the pre-reforming reaction in reverse contact with the...

Embodiment 3

[0048] 1, a kind of method (conversion absorption tower temperature is 90 ℃, and pressure is 0.03Mpa) of producing sodium nitrate by continuous conversion, comprises the following steps:

[0049] (1) Pre-transformation stage:

[0050] a. Turn on the conversion circulating pump 2, adjust the circulating liquid to the middle circulating liquid inlet 5 and the upper circulating liquid inlet 7 of the conversion absorption tower 12 through the valve adjustment, and evenly distribute the liquid through the distributor 13;

[0051] B, the mixed mother liquor of sodium nitrite and sodium nitrate is sent into the middle part mother liquor inlet 6 and the upper mother liquor inlet 8 of conversion absorption tower 12 respectively through mother liquor flow regulating valve 22, and is evenly distributed through distributor 13;

[0052] c. In the upper pre-reforming section 14, mix the mother liquor and circulating liquid to absorb the tail gas from the bottom of the conversion absorption ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com