Method for cracking sludge by virtue of singlet oxygen

A singlet oxygen and sludge technology, applied in the oxidation treatment of sludge, sludge treatment, chemical instruments and methods, etc., can solve the problems of occupying a large amount of land, waste of sludge available resources, ecological damage, etc., and achieve moderate prices. , non-toxic and side effects, the effect of improving dehydration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

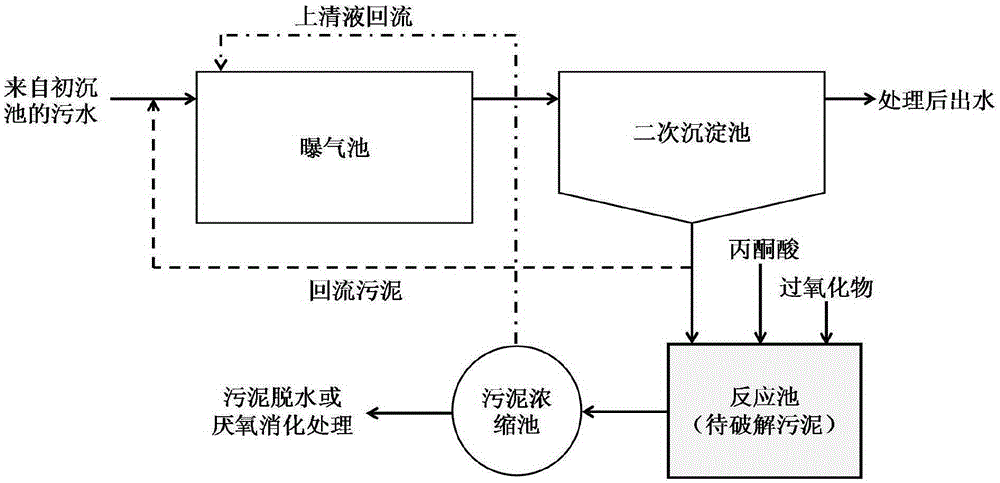

[0022] Specific embodiment one: a kind of method utilizing singlet oxygen of the present invention to crack sludge is realized through the following steps:

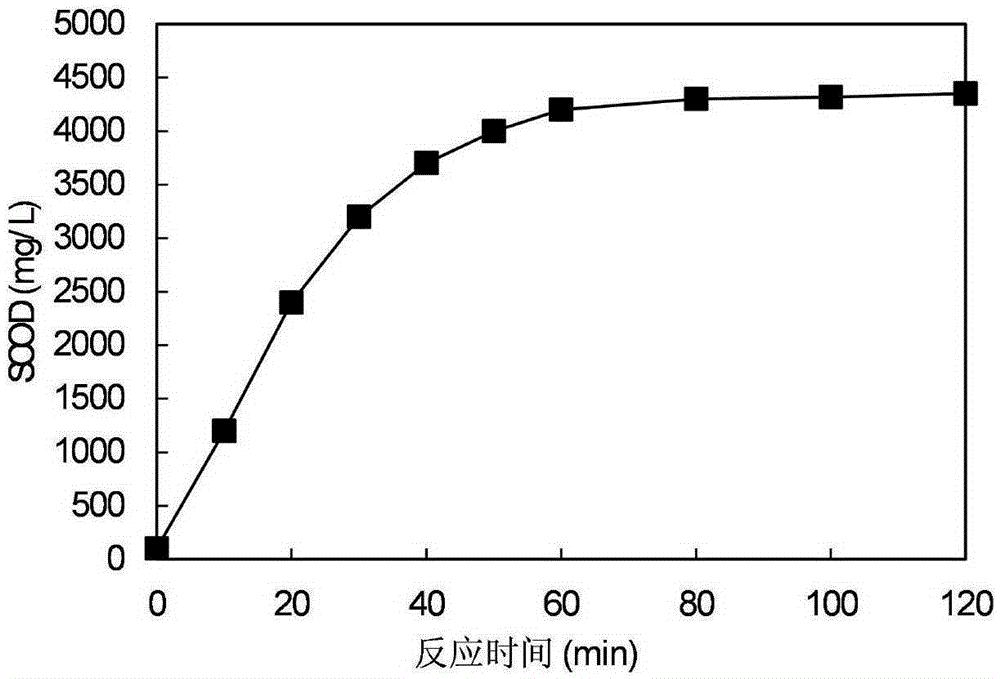

[0023] 1. Add the catalyst and oxidant to the sludge to be decomposed at a molar ratio of 1:(1~10), control the concentration of peroxide in the sludge to 1000~10000mg / L, and the reaction time is 30~ 120min, keep stirring during the process;

[0024] 2. Thicken the cracked sludge, and then return the supernatant to the aeration tank;

[0025] 3. Perform sludge dehydration or anaerobic digestion treatment on the remaining sludge after the concentrated treatment in the previous step, that is, complete the use of singlet oxygen to crack the sludge; wherein the catalyst is pyruvic acid, and the oxidant for peroxides.

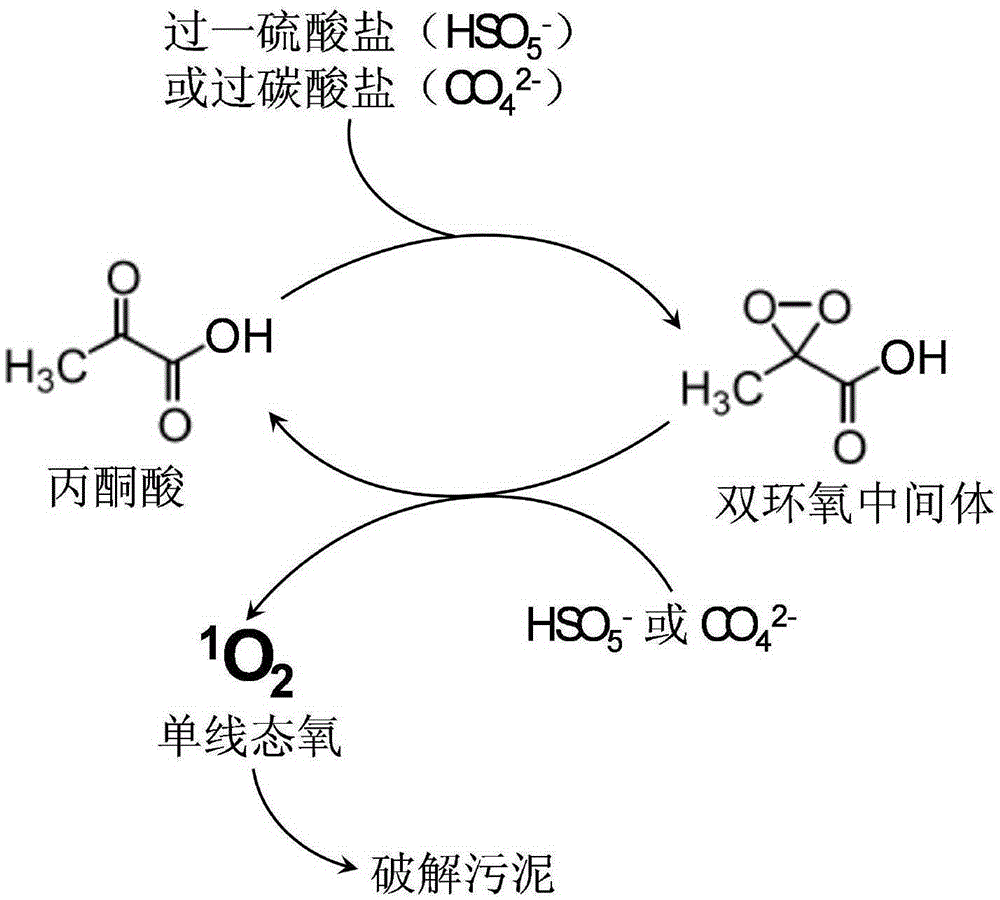

[0026] The principle of a method for utilizing singlet oxygen to decompose sludge in this embodiment is as follows: first, pyruvic acid catalyzes peroxide (permonosulfate, percarbonate) to produce a diepoxy i...

specific Embodiment approach 2

[0028] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the peroxide is a mixture of one or more of persulfate and percarbonate in any ratio. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0029] Specific embodiment three: the difference between this embodiment and specific embodiment one is: the persulfate is sodium persulfate (NaHSO 5 ), potassium persulfate (KHSO 5 ), ammonium persulfate (NH 4 HSO 5 ), calcium persulfate (Ca(HSO 5 ) 2 ), magnesium persulfate (Mg(HSO 5 ) 2 ) in one or several mixtures in any ratio. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com