Preparation method of flame retardant organosilicon cyclic phosphine compound

A technology of phosphine compound and organosilicon, which is applied in the field of preparation of flame retardant alkyl trisilane compound, can solve the problems of limited application range, and achieve the effects of easy large-scale production, prevention of melt dripping, and high decomposition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

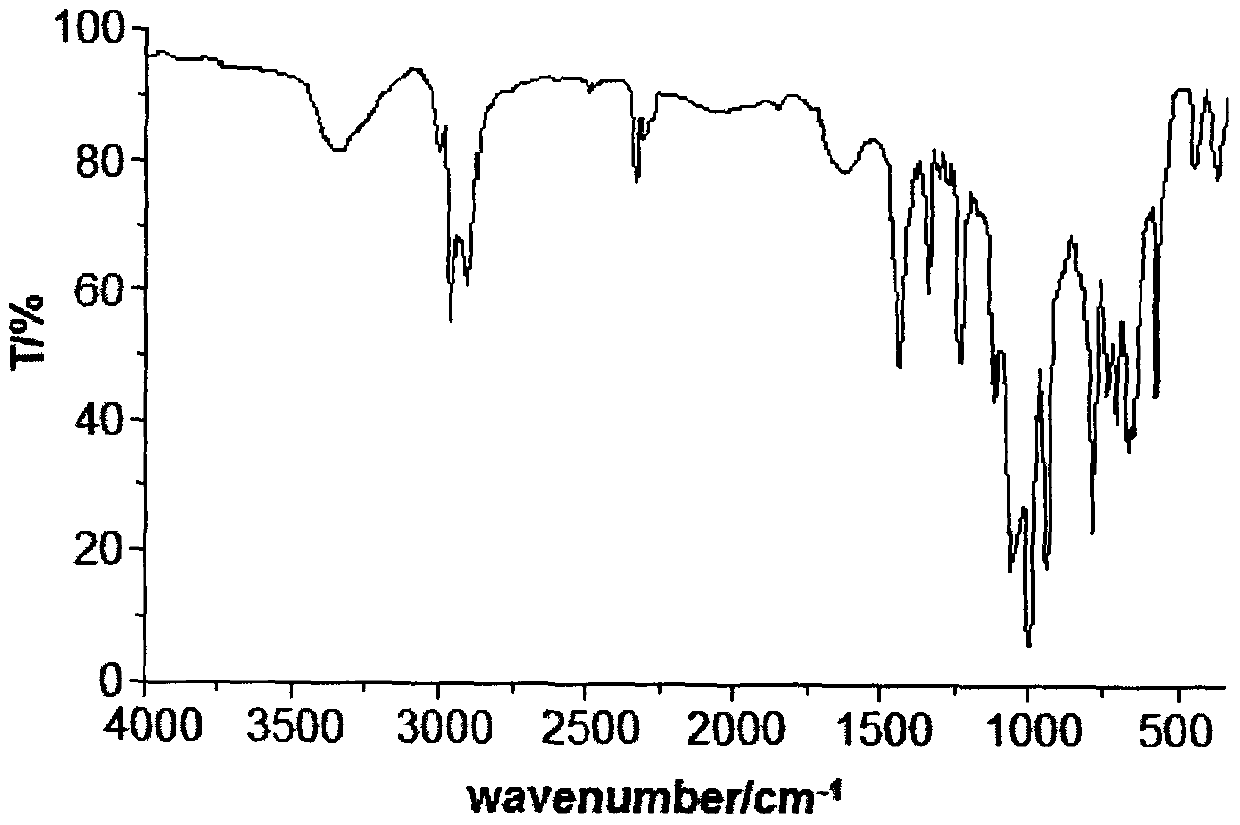

Embodiment 1

[0035] Example 1 In a 200ml four-neck flask equipped with a stirrer, a thermometer, a high-efficiency reflux condenser and a hydrogen chloride absorption device, replace the air in the bottle with nitrogen, and add 45ml of dioxane and 32.01g (0.165mol) of 4-hydroxyl Methyl-4-ethyl-cyclic methylphosphonate, add 7.47g (0.05mol) methyltrichlorosilane dropwise under stirring, control the dropwise addition temperature not to exceed 60°C, and raise the temperature to 80°C after dropping, react After 18 hours, after the hydrogen chloride was released, it was changed to a vacuum distillation device, and the dioxane (recycled) was removed by vacuum distillation, and then 35ml of distilled water was added, stirred to disperse the solid in water, suction filtered, and rinsed with water until pH = 7. Dry to obtain white solid methyl tris(1-oxo-1-methyl-4-ethyl-1-phospha-2,6-dioxa-cyclohexyl--methoxy base) silane, product yield 95.4%, its melting point: 75°C±2°C, decomposition temperature:...

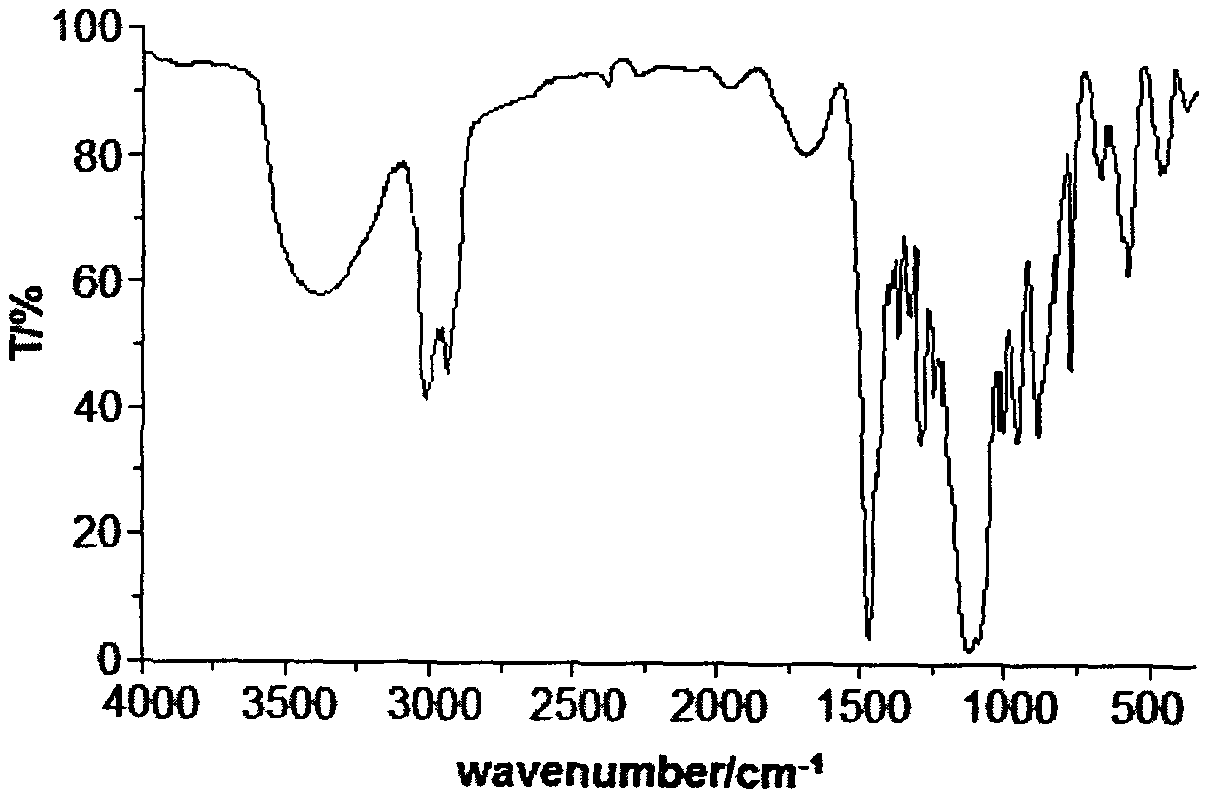

Embodiment 2

[0036] Example 2 In a 200ml four-neck flask equipped with a stirrer, a thermometer, a high-efficiency reflux condenser and a hydrogen chloride absorption device, replace the air in the bottle with nitrogen, and add 65ml xylene and 29.1g (0.15mol) 4-hydroxymethyl -4-Ethyl-cyclic methylphosphonate, add 7.47g (0.05mol) methyltrichlorosilane dropwise under stirring, control the dropping temperature not to exceed 60°C, raise the temperature to 100°C after dropping, and react for 15h, After the hydrogen chloride is discharged, change it to a vacuum distillation device, and remove xylene by vacuum distillation (recycling), then add 40ml of distilled water, stir to disperse the solid in water, filter with suction, wash with water until pH = 7, and dry , to obtain white solid methyl tris(1-oxo-1-methyl-4-ethyl-1-phospha-2,6-dioxa-cyclohexyl--methoxy)silane, The product yield is 80.7%, its melting point: 75°C±2°C, decomposition temperature: 250°C±5°C.

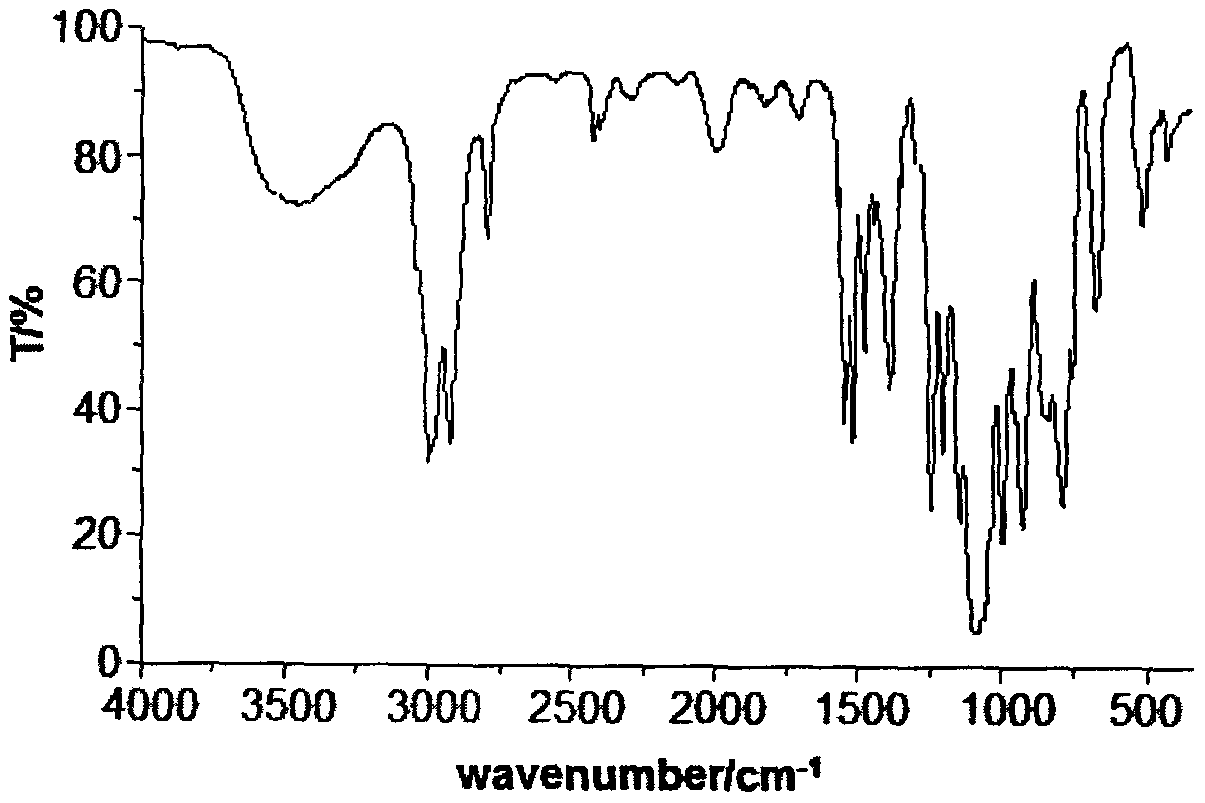

Embodiment 3

[0037] Example 3 In a 200ml four-necked flask equipped with a stirrer, a thermometer, a high-efficiency reflux condenser and a hydrogen chloride absorption device, the air in the bottle was replaced with nitrogen, and 40ml of toluene and 30.07g (0.155mol) of 4-hydroxymethyl- 4-Ethyl-cyclic methylphosphonate, add 7.47g (0.05mol) methyltrichlorosilane dropwise under stirring, control the dropping temperature not to exceed 60°C, raise the temperature to 110°C after dropping, react for 13h, wait After the hydrogen chloride is released, change it to a vacuum distillation device, and remove the toluene (recycled) by vacuum distillation, then add 45ml of distilled water, stir to make the solid disperse in water, filter with suction, rinse with water until pH=7, and dry to obtain White solid methyltris(1-oxo-1-methyl-4-ethyl-1-phospha-2,6-dioxa-cyclohexyl--methoxy)silane, the product was The yield is 83.8%, its melting point: 75℃±2℃, decomposition temperature: 250±5℃.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com