A kind of synthesis method of ultra-high temperature resistant zrc/sic composite ceramic precursor

A technology of multiphase ceramics and synthesis method, which is applied in the field of synthesis of ultra-high temperature resistant ZrC/SiC multiphase ceramic precursors, can solve the problems of low zirconium content in products, poor ceramic performance, low utilization rate of zirconium sources, etc., to achieve purity High, low oxygen content, high zirconium utilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

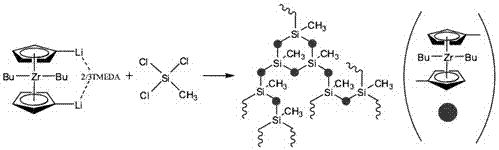

Method used

Image

Examples

Embodiment 1

[0041] This embodiment includes the following steps:

[0042] (1) Put 5 g (17.1 mmol) of zirconocene dichloride in the flask; evacuate the reaction system, then replace the gas in the reaction system with nitrogen to normal pressure, repeat 3 times; stir, add 60 mL of anhydrous Oxygen in n-hexane was dissolved, 3.8 mL (25.6 mmol) of TMEDA was added, and 79.2 mmol of n-butyllithium (33 mL of commercially available 2.4 mol / L n-butyllithium in n-hexane solution) was added dropwise, and the reaction was carried out for 12 hours. Wash and vacuum dry to obtain 8.1 g of active dibutyl zirconocene dilithium salt (component a);

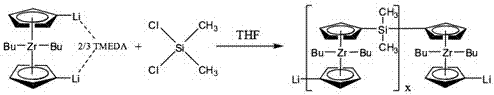

[0043] (2) Under the protection of nitrogen atmosphere, dissolve 5 g (11.8 mmol) of component a obtained in step (1) in 50 mL of anhydrous and oxygen-free tetrahydrofuran to obtain solution I; add 2.5 ml (13.1 mmol) of methyltrichlorosilane to Dissolve in 30 mL of anhydrous and oxygen-free tetrahydrofuran to obtain solution II; drop solution II into solution ...

Embodiment 2

[0051] This embodiment includes the following steps:

[0052] (1) Put 10 g (34.2 mmol) of zirconocene dichloride in the flask; evacuate the reaction system, and then replace the gas in the reaction system with argon to normal pressure, repeat 3 times; stir, add 80 mL of anhydrous Dissolve in anaerobic tetrahydrofuran, add 7.6 mL (51.3 mmol) of TMEDA, and dropwise add 158.4 mmol of n-butyllithium (66 mL of commercially available 2.4 mol / L n-butyllithium in n-hexane solution), react for 7 hours, and filter under reduced pressure , washed, and dried under vacuum to obtain 18.6 g of active dibutyl zirconocene dilithium salt (component a);

[0053] (2) Under the protection of nitrogen atmosphere, dissolve 5 g (11.8 mmol) of the component a obtained in step (1) in 50 mL of anhydrous and oxygen-free tetrahydrofuran to obtain a solution I; Chlorosilane was dissolved in 30 mL of anhydrous and oxygen-free tetrahydrofuran to obtain solution II of halosilane monomer dimethyldichlorosilan...

Embodiment 3

[0057] This embodiment includes the following steps:

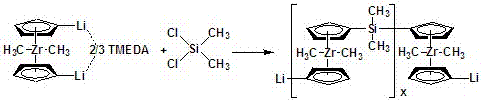

[0058] (1) Place 10 g (34.2 mmol) of zirconocene dichloride in a flask; evacuate the reaction system, then replace the gas in the reaction system with nitrogen to normal pressure, repeat 3 times; stir, add 80 mL of anhydrous Oxytetrahydrofuran was dissolved, 7.6 mL (51.3 mmol) of TMEDA was added, and 144 mmol of methyllithium (90 mL of a commercially available 1.6 mol / L methyllithium solution in ether) was added dropwise, and the reaction was carried out for 10 hours, filtered under reduced pressure, washed, and dried in vacuo , to obtain active dimethyl zirconocene dilithium salt (component a);

[0059] (2) Under the protection of nitrogen atmosphere, dissolve 5 g (15.8 mmol) of the component a obtained in step (1) in 50 mL of anhydrous and oxygen-free tetrahydrofuran to obtain a solution I; 2.3 ml (16.7 mmol) of dimethyl dimethyl After the chlorosilane was dissolved in 30 mL of anhydrous and oxygen-free tetrahydrofuran,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength retention | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com