Ultraviolet light polymerization adhesive

A technology of adhesives and ultraviolet light, applied in adhesives, modified epoxy resin adhesives, non-polymer adhesive additives, etc., can solve problems such as poor moisture resistance, reduced bonding strength, and reduced bonding strength , to achieve the effect of good moisture resistance, good moisture resistance and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

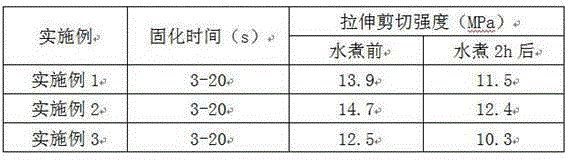

Examples

Embodiment 1

[0011] Embodiment 1: Adhesive is made up of the raw material of following parts by weight, listed in the following table:

[0012] polybutadiene dimethacrylate 20 Trifunctional aromatic urethane acrylate 20 Trifunctional epoxy acrylate 10 Propoxylated Trimethylolpropane Triacrylate 50 Irgacure 184 0.5 Irgacure 819 0.5 A-172 silane coupling agent 10

[0013] The viscosity of polybutadiene dimethacrylate at 50°C is 65000cps, the viscosity of trifunctional aromatic urethane acrylate at 50°C is 5200cps, and the viscosity of trifunctional epoxy resin acrylate at 50°C is 2500cps.

[0014] Preparation process: Add the above components into a double planetary power mixer in turn, vacuumize to about -0.1MPa, stir at a speed of 500r / min for 2 hours, then let it air naturally to room temperature, and then discharge and pack. Note that the operation process after adding the initiator should be kept in a dark state.

[0015] How to use: ① ...

Embodiment 2

[0016] Embodiment 2: Adhesive is made up of the raw material of following parts by weight, listed in the following table:

[0017] polybutadiene dimethacrylate 40 Hexafunctional Aromatic Urethane Acrylate 20 Isobornyl Acrylate 20 tetrahydrofuran acrylate 20 TPO 5 CD9051 5 1121 adhesion promoter 5

[0018] The six-functional aromatic urethane acrylate has a viscosity of 1800 cps at 50°C. The preparation process and method of use are the same as in Example 1.

Embodiment 3

[0019] Embodiment 3: Adhesive is made up of the raw material of following parts by weight, listed in the following table:

[0020] polybutadiene dimethacrylate 60 Trifunctional epoxy acrylate 10 dipentaerythritol pentamethacrylate 20 Ethoxylated bisphenol A diacrylate 10 Darocure 1173 2 1121 adhesion promoter 5 Phosphate methacrylate 0.1

[0021] The preparation process and method of use are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com