Multi-functional nanometer MgO vanadium inhibitor and preparation method and application thereof

A vanadium inhibitor, multi-functional technology, used in fuel additives, petroleum industry, liquid carbon-containing fuels, etc., can solve the problems of inability to store for a long time, complex preparation process, wear of fuel pumps and flow distributors, etc., to improve independent research and development. Ability and promotion and application, no three-waste pollution, and the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In parts by mass, add 20 parts of technical grade MgO, 40 parts of heavy alkylbenzene, 50 parts of trimethylbenzenes, 1 part of terpene resin, 4 parts of oleic acid, 25 parts of distilled water and 6 parts of glacial acetic acid in the reactor. The temperature was raised to 105° C. under stirring, and the reaction was maintained for 2.5 hours, and the water in the reaction system was removed by a water separator to obtain a nano-MgO precursor.

[0024] The above-mentioned nano-MgO precursor was heated to 230 °C, and the mixed trimethylbenzene in the system was continuously removed during the heating process, and then the temperature was continued to be raised to 330 °C and kept for 3 hours, and part of the solvent evaporated and the water generated during the reaction were collected. The product is a brown-gray translucent fluid containing 17% Mg. The physical and chemical properties of this product are shown in Table 1.

Embodiment 2

[0026] The products in Example 1 were concentrated by distillation under reduced pressure to obtain products with Mg contents of 25%, 35% and 45%, respectively. These products are translucent fluids with good fluidity, good storage stability, no particle precipitation after being placed for 12 months, no precipitation in water, good dispersion in oil, and no insoluble matter. The physical and chemical properties of the products are shown in Table 1. shown.

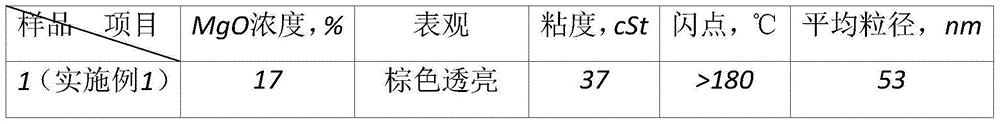

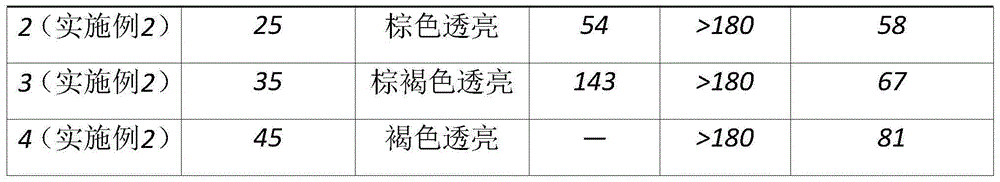

[0027] Table 1

[0028]

[0029]

Embodiment 3

[0031] In parts by mass, 16 parts of reagent grade MgO, 30 parts of decene oligomers, 60 parts of mixed tetramethylbenzene, 2 parts of terpene resins, 8 parts of dodecylbenzenesulfonic acid, 15 parts of distilled water and 2 parts of glacial acetic acid were heated up to 110°C under stirring, kept for 3 hours, and the water in the reaction system was removed by a water separator to obtain a nano-MgO precursor.

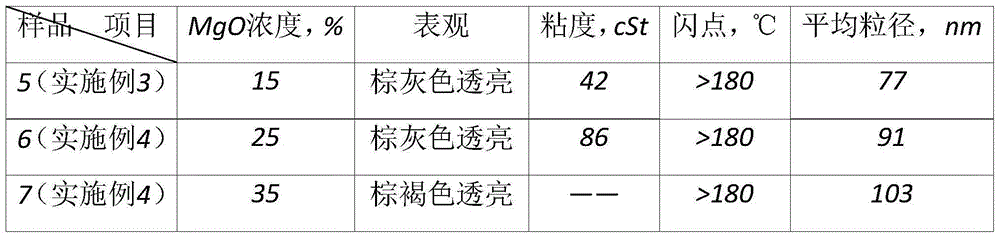

[0032] Raise the temperature of the above-mentioned nano-MgO precursor to 300°C, keep it warm for 4 hours, and collect the evaporated part of the solvent and the water generated during the reaction. The product obtained is a brownish-gray translucent fluid with good fluidity, and the Mg content of this product is 15%. , the physical and chemical properties are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com