High-performance mesoporous-micro double hole controllable molecular sieve adsorbent and preparation and application thereof

A high-performance, molecular sieve technology, applied in other chemical processes, chemical instruments and methods, silicates, etc., can solve the problems of limiting the adsorption performance of activated carbon, the decrease of VOCs adsorption, and unfavorable industrial applications, so as to achieve good application prospects and shorten the Synthesis time, the effect of short synthesis time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Follow the steps below to prepare a high-performance meso-micro double-porous controllable molecular sieve adsorbent:

[0040] (1) Add 8.12g of tetrapropylammonium hydroxide (TPAOH, 25% aqueous solution) into 20mL of distilled water, stir at room temperature until evenly mixed, then add 0.102g of aluminum isopropoxide, stir until aluminum isopropoxide is completely hydrolyzed; weigh Tetraethyl orthosilicate 10.4g was added dropwise to the above solution under stirring at 750r / min to obtain liquid A;

[0041] (2) Dissolve 1.5g of sodium tetradecylsulfonate into 16mL of distilled water, stir in a water bath at 40°C, and after 1 hour, add 0.3g of 3-chloropropyltriethoxysilane to the solution to obtain liquid B;

[0042] (3) Quickly add liquid B prepared in step (2) to liquid A prepared in step (1), adjust pH=9.7, and stir for 2 hours to obtain mother liquor;

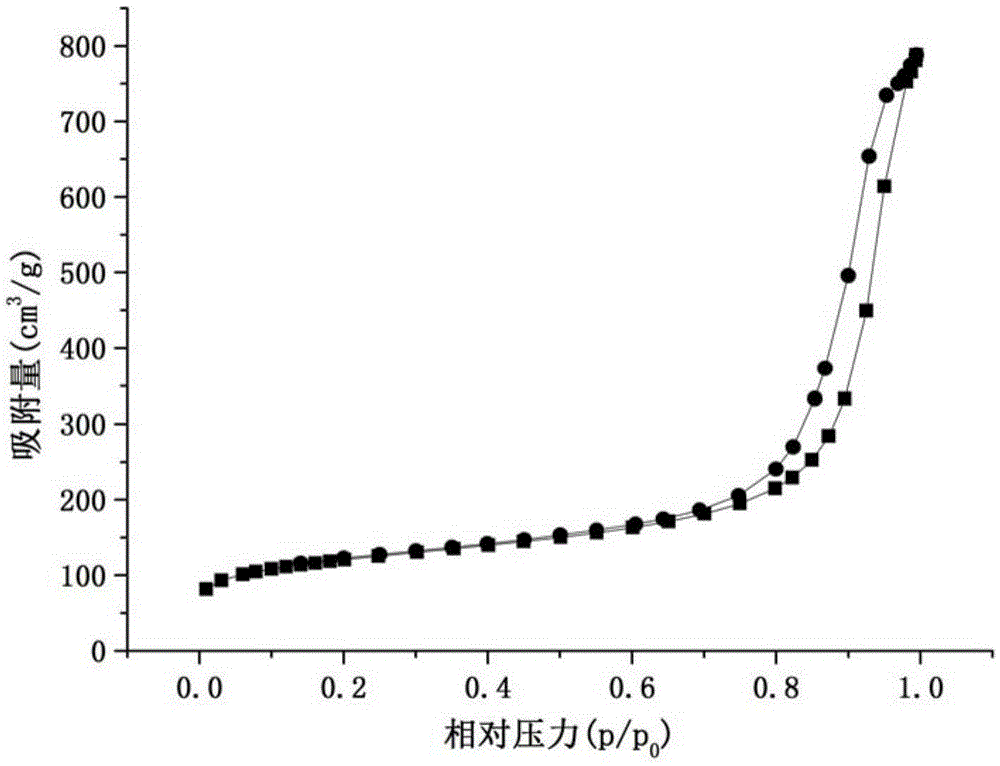

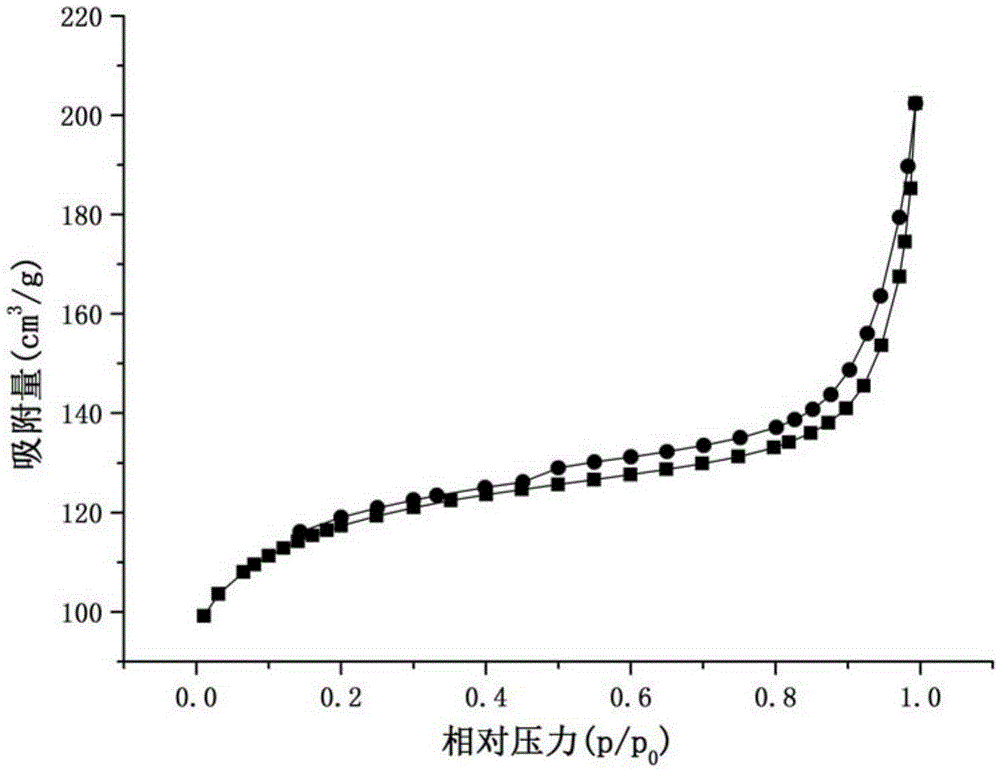

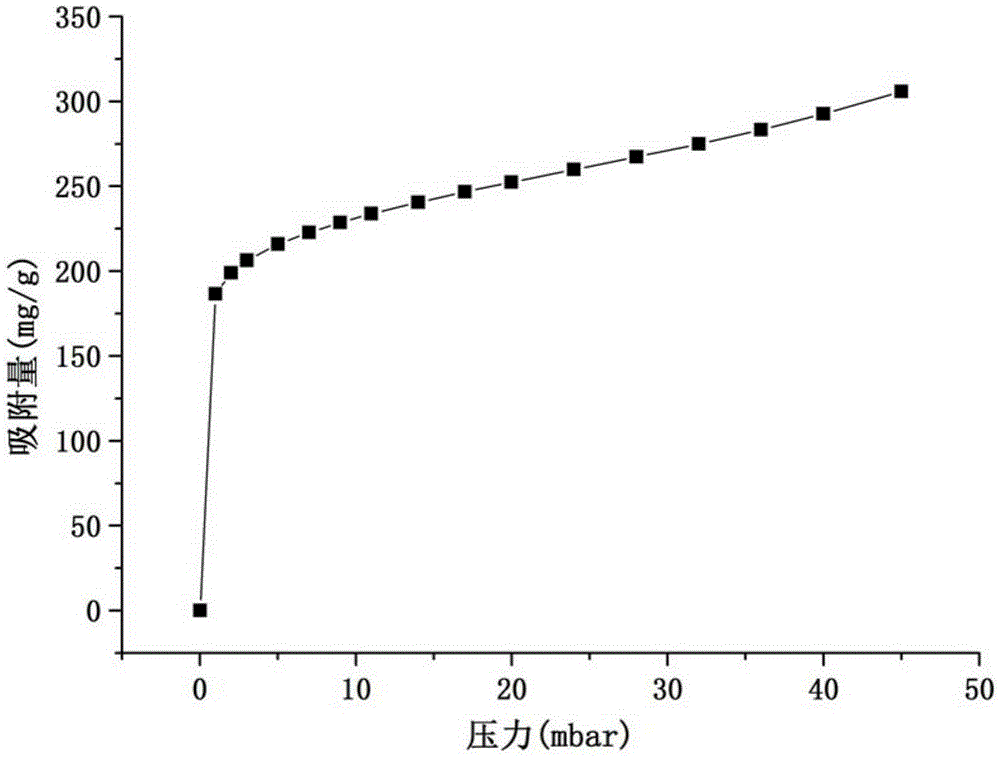

[0043] (4) Transfer the mother liquor prepared in step (3) into a 100mL polytetrafluoroethylene reactor, and conduc...

Embodiment 2

[0045] Follow the steps below to prepare a high-performance meso-micro double-porous controllable molecular sieve adsorbent:

[0046] (1) Add 8.12g of tetrapropylammonium hydroxide (TPAOH, 25% aqueous solution) into 20mL of distilled water, stir at room temperature until evenly mixed, then add 0.204g of aluminum isopropoxide, and stir until the aluminum isopropoxide is completely hydrolyzed. Weigh 10.4 g of tetraethyl orthosilicate, and drop into the above solution drop by drop under stirring at 750r / min to obtain liquid A;

[0047] (2) Dissolve 3.28g of sodium n-hexadecylsulfonate into 16mL of distilled water, stir in a water bath at 40°C, and after 1 hour, add 1.1g of 3-aminopropyltriethoxysilane to the solution to obtain liquid B;

[0048] (3) Quickly add liquid B prepared in step (2) to liquid A prepared in step (1), adjust pH=8.8, stir for 2 hours,

[0049] (4) Transfer the mixed solution into a 100mL polytetrafluoroethylene reaction kettle, and conduct a hydrothermal re...

Embodiment 3

[0051] Follow the steps below to prepare a high-performance meso-micro double-porous controllable molecular sieve adsorbent:

[0052] (1) Add 8.12g of tetrapropylammonium hydroxide (TPAOH, 25% aqueous solution) into 20mL of distilled water, stir at room temperature until evenly mixed, then add 0.408g of aluminum isopropoxide, stir until aluminum isopropoxide is completely hydrolyzed; weigh Tetraethyl orthosilicate 10.4g was added dropwise to the above solution under stirring at 750r / min to obtain liquid A;

[0053] (2) Dissolve 3.48g of sodium dodecylbenzenesulfonate into 16mL of distilled water and stir in a water bath at 40°C. After 1 hour, add 0.55g of 3-aminopropyltriethoxysilane to the solution to obtain liquid B;

[0054] (3) Quickly add liquid B prepared in step (2) into liquid A prepared in step (1), adjust pH=9.7, stir for 2 hours,

[0055] (4) Transfer the mixed solution into a 100mL polytetrafluoroethylene reactor, and conduct a hydrothermal reaction at 140°C for 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Specific surface | aaaaa | aaaaa |

| Total pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com