Method for desalinating thymopeptide alpha 1

A thymosin and desalination technology, applied in the field of desalination of thymosin α1, can solve the problems of long time consumption of ion exchange resin, small amount of sample processing, low work efficiency, etc., and achieve the effect of easy industrial implementation, low environmental pollution and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] 1. Sample treatment: After weighing 5g of thymosin α1 and dissolving it, adjust the pH value of the solution to 7, filter through a filter membrane with a pore size of 0.45um, and collect the filtrate.

[0015] 2. Desalination

[0016] Conditions: Chromatographic column: a chromatographic column with octadecyl silica gel bonded silica gel as the stationary phase, the diameter and length of the column are: 5cm×25cm. Mobile phase: A phase: aqueous solution; B phase: methanol solution. Flow rate: 60-80ml / min. Detection wavelength: 220nm. Concentration gradient: B%: 20-60%, 30-50min.

[0017] Process: equilibrate the chromatographic column with phase B with a concentration of 5% by mass, load the sample, elute with a linear gradient, collect the target peak, and place the collected peptide solution in a collection bottle.

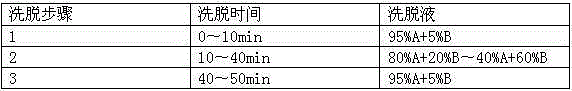

[0018]

[0019] 3. All the peptide solutions obtained after salt conversion were concentrated under reduced pressure to 1g / 50ml, the concentratio...

Embodiment 2

[0021] 1. Sample treatment: After weighing 40g of thymosin α1 and dissolving it, adjust the pH of the solution to 8, filter through a filter membrane with a pore size of 0.45um, and collect the filtrate.

[0022] 2. Desalination

[0023] Conditions: Chromatographic column: a chromatographic column with octadecyl silica gel bonded silica gel as the stationary phase, the diameter and length of the column are: 10cm×25cm. Mobile phase: Phase A: aqueous solution; phase B: methanol solution. Flow rate: 180-200ml / min. Detection wavelength: 220nm. Concentration gradient: B%: 20-60%, 30-50min.

[0024] Process: equilibrate the chromatographic column with phase B with a concentration of 5% by mass, load the sample, elute with a linear gradient, collect the target peak, and place the collected peptide solution in a collection bottle.

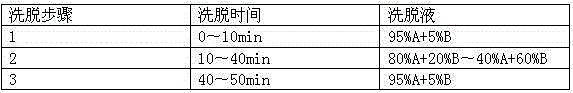

[0025]

[0026] 3. All the peptide solutions obtained after salt conversion were concentrated under reduced pressure to 1g / 50ml, the concentration ...

Embodiment 3

[0028] 1. Sample treatment: Quantitatively purify thymosin α1, the content of the solution is 5.5g, adjust the pH value of the solution to 6.5, filter through a filter membrane with a pore size of 0.45um, and collect the filtrate.

[0029] 2. Desalination

[0030] Conditions: Chromatographic column: a chromatographic column with octadecyl silica gel bonded silica gel as the stationary phase, the diameter and length of the column are: 5cm×25cm. Mobile phase: Phase A: aqueous solution; phase B: methanol solution. Flow rate: 60-80ml / min. Detection wavelength: 220nm. Concentration gradient: B%: 20-60%, 30-50min.

[0031] Process: Equilibrate the chromatographic column with phase B with a concentration of 5% by mass and load the sample. Linear gradient elution, collect the target peak, put the collected peptide solution into the collection bottle.

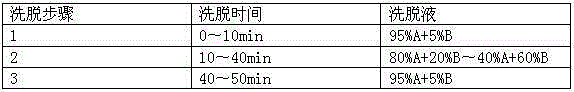

[0032]

[0033] 3. All the peptide solutions obtained after salt conversion were concentrated under reduced pressure to 1g / 50m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com