Environment-friendly soft PVC plasticizer

An environment-friendly plasticizer technology, applied in the field of preparation and modification of functional polymer materials, can solve problems such as endocrine system damage, reproductive development, and adverse effects on infant growth and development, and achieve good durability and compatibility good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] An environment-friendly soft PVC plasticizer is composed of the following components in parts by weight:

[0023] 60 parts of cage silicone hybrid star polyester;

[0024] 20 parts of fatty acid methyl ester;

[0025] 25 parts of epoxy fatty acid methyl ester;

[0026] 5 parts of benzoic acid;

[0027] 5 parts of ethylene glycol;

[0028] 4 parts of carbonamide;

[0029] 7 parts of soluble polyvinyl alcohol;

[0030] 4 parts of epoxidized soybean oil.

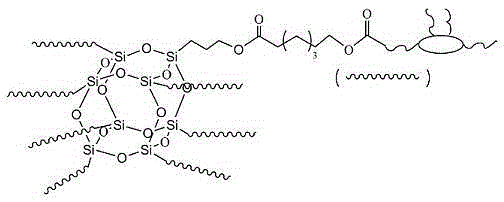

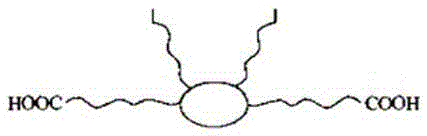

[0031] The cage-type organosilicon hybrid star polyester is prepared by the following method: (1) ricinoleic acid is sequentially cleaved and oxidized by ozone oxidation, and Pd / C catalyzed hydrogenation reaction to obtain nonanol acid and 1,3- Mixed product of dihydroxynonanediol; (2) The vertex group of octamethacryloxypropyl cage silsesquioxane undergoes ester hydrolysis reaction in aqueous sulfuric acid solution, stirring and refluxing for 4 hours to obtain octapropanol (3) the mixed product obtained in step (...

Embodiment 2

[0034] The composition of this embodiment is the same as that of Example 1, except that the environment-friendly soft PVC plasticizer is composed of the following components in parts by weight:

[0035] 65 parts of cage silicone hybrid star polyester;

[0036] 20 parts of fatty acid methyl ester;

[0037] 25 parts of epoxy fatty acid methyl ester;

[0038] 5 parts of benzoic acid;

[0039] 5 parts of ethylene glycol;

[0040] 5 parts of carbonamide;

[0041] 7 parts of soluble polyvinyl alcohol;

[0042] 4 parts of epoxidized soybean oil.

[0043] After adding the above plasticizer, the plasticizing time of PVC is 1.1 minutes, the plasticizing is easy, the plasticizing performance is good, and the plasticizing efficiency is high.

Embodiment 3

[0045] The composition of this embodiment is the same as that of Example 1, except that the environment-friendly soft PVC plasticizer is composed of the following components in parts by weight:

[0046] 70 parts of cage silicone hybrid star polyester;

[0047] 20 parts of fatty acid methyl ester;

[0048] 25 parts of epoxy fatty acid methyl ester;

[0049] 5 parts of benzoic acid;

[0050] 5 parts of ethylene glycol;

[0051] 4 parts of carbonamide;

[0052] 7 parts of soluble polyvinyl alcohol;

[0053] 4 parts of epoxidized soybean oil.

[0054] After adding the above plasticizer, the plasticizing time of PVC is 1.0 minute, the plasticizing is easy, the plasticizing performance is good, and the plasticizing efficiency is high.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com