A method for improving ethanol production efficiency by overexpressing the ino2 gene

A production efficiency, alcohol technology, applied in the field of bioenergy development, can solve the problems of difficult control inhibition, poison inhibition, etc., and achieve the effect of good industrial application value and prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: Construction of Saccharomyces cerevisiae Genetic Engineering Bacteria

[0034] Using the ino4 single-gene deletion strain YOL108C purchased from Invotrogen Company and numbered Sc04163923_s1 as the starting strain, the overexpression is by constructing a high-expression plasmid pHAC181-INO2. stop codon), and then clone this fragment into the high-expression plasmid pHAC181, and finally carry out DNA sequencing on the correct recombinant, verify that the sequence does not mutate, and finally obtain the recombinant high-expression plasmid pHAC181-INO2, and then pass the lithium acetate method. pHAC181-INO2 was introduced into the ino4 single gene deletion strain to obtain a strain with high expression of INO2 gene.

Embodiment 2

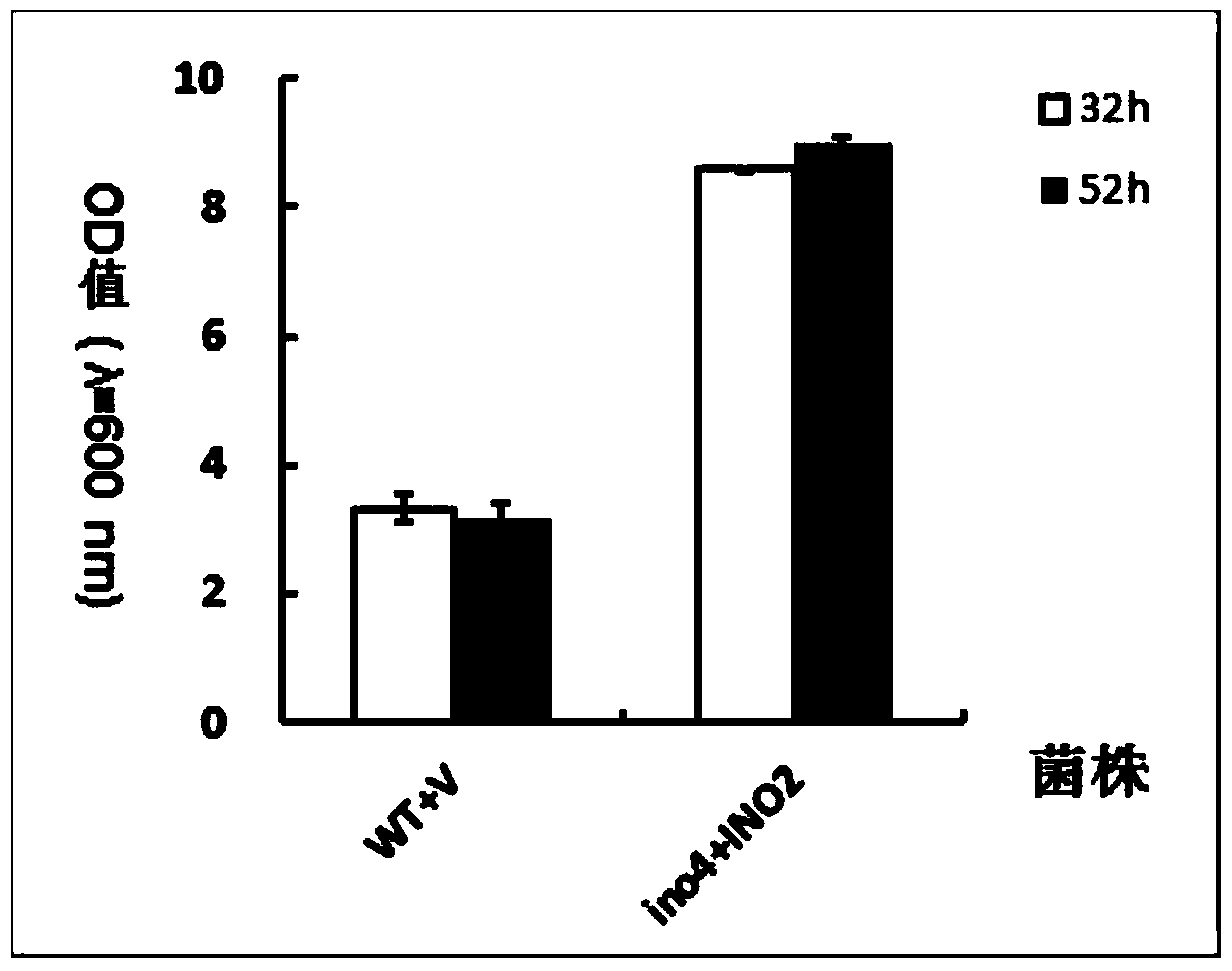

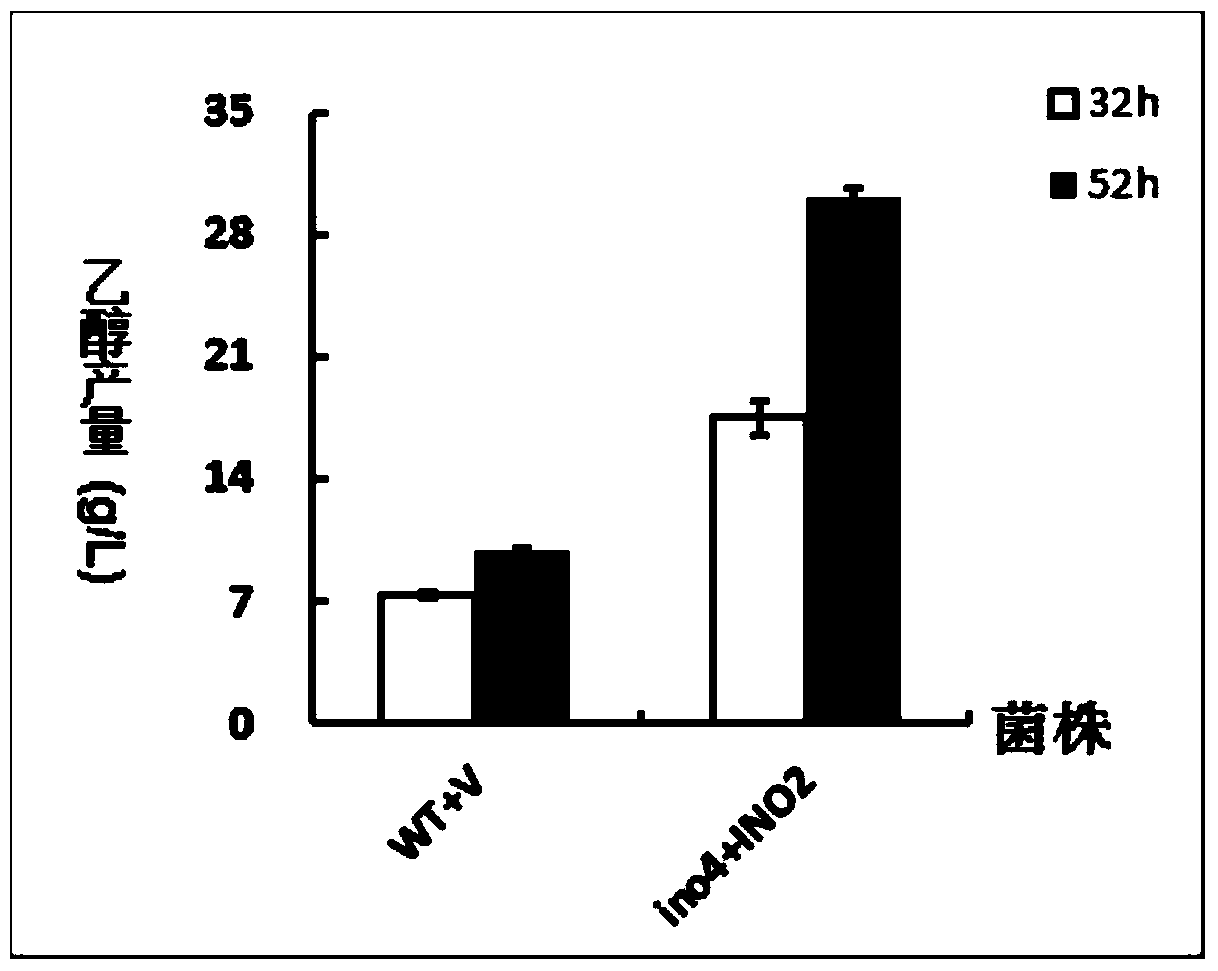

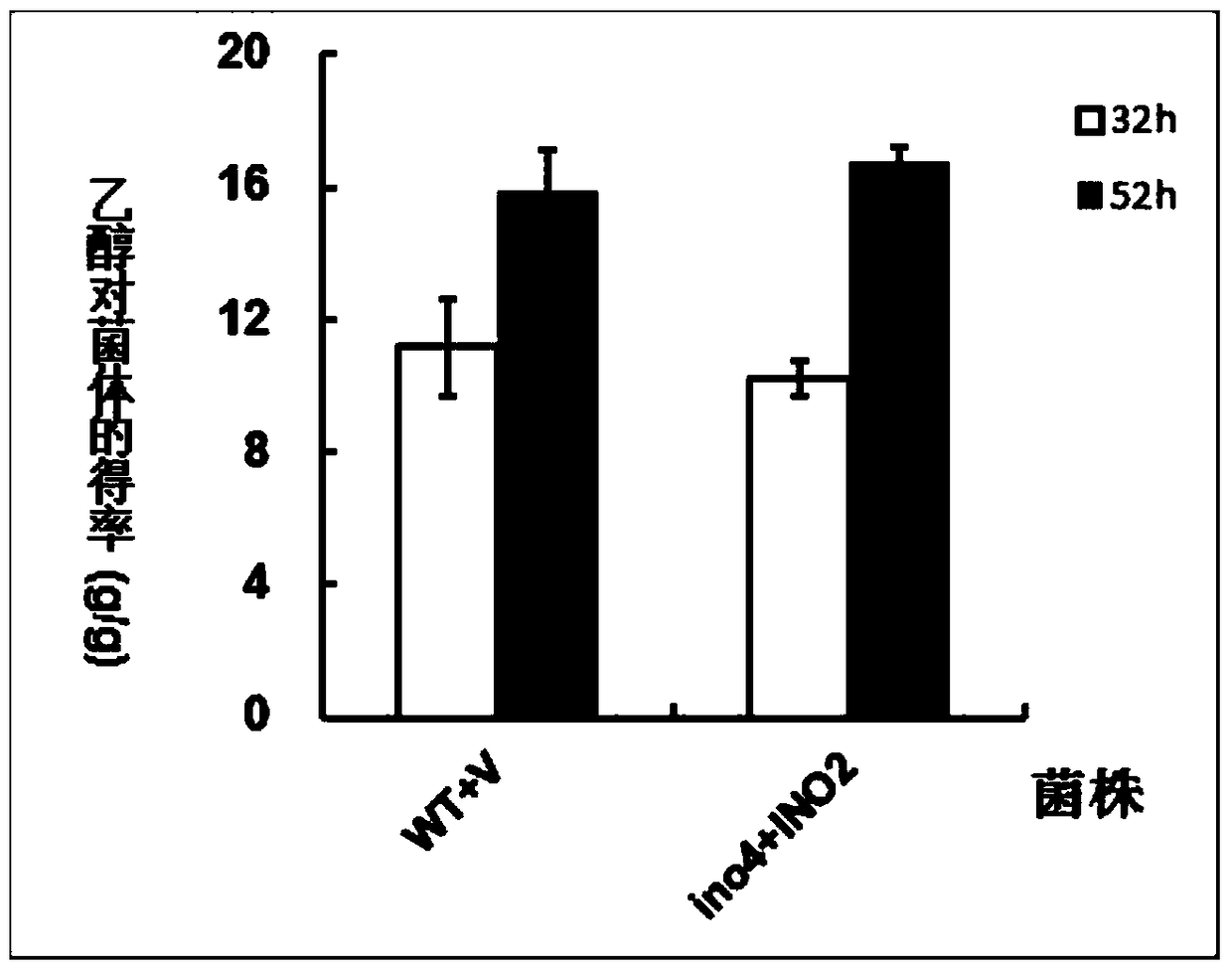

[0035] Example 2: Saccharomyces cerevisiae alcoholic fermentation

[0036] Prepare YPD plate and YPD liquid medium in advance according to the preparation method of solid medium.

[0037]Streak activation of Saccharomyces cerevisiae genetically engineered bacteria of the present invention, wild-type strain BY4743BG (BY4743 containing G418 resistance gene) and Saccharomyces cerevisiae strain YOL108C with ino4 single gene deletion on YPD plate; ino4 single gene deletion strain YOL108C is in BY4743BG background obtained by replacing the gene INO4 with the G418 resistance gene in bacteria; (http: / / clones.lifetechnologies.com / cloneinfo.php?clone=yeast). The YPD plate was placed in a constant temperature incubator at 30°C for 2 days. Working in an ultra-clean bench, take a large single colony from each activated strain plate and inoculate it in 30 mL of YPD liquid medium, culture it on a shaker at 220 r / min at 30°C for 23 hours until saturated. After culturing for 23 hours, add 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com