Enzymolysis preparation method of new agaro oligosaccharides

A new agar oligosaccharide and enzymatic hydrolysis technology, applied in the field of bioengineering, can solve the problems of not being absorbed and utilized by organisms, limited application of agar gel, insoluble in cold water, etc., and achieve the effect of low cost, low price and abundant sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Example 1 Process optimization for preparing agar by extracting asparagus by water

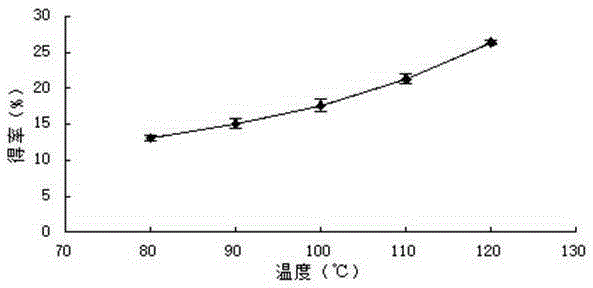

[0046] (1) When the ratio of liquid to material is 16:1 and the time is 60 minutes, the optimum water extraction temperature is determined to be 120°C ( figure 1 ).

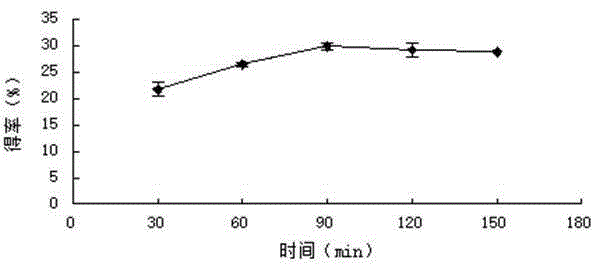

[0047] (2) At a temperature of 120°C and a liquid-to-solid ratio of 16:1, determine the optimum water extraction time to be 90 minutes ( figure 2 ).

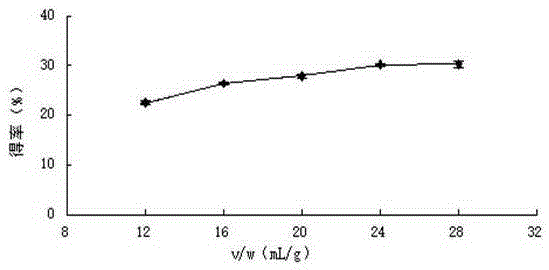

[0048] (3) At a temperature of 120°C and a time of 90 minutes, determine the optimum water-extraction liquid-material ratio of 24:1 ( image 3 ).

[0049] On the basis of single factor experiment, adopt orthogonal test to carry out the optimization of water extraction agar, according to L 9 (3 4 ) orthogonal table for temperature (100°C, 110°C, 120°C); time (60min, 90min, 120min); liquid-to-solid ratio (20:1, 24:1, 28:1) orthogonal test, the factor level table is as follows Table 1 shows.

[0050] Table 1 Factor level table

[0051]

[0052] Analysis of the re...

Embodiment 2

[0055] Enzymatic hydrolysis preparation process optimization of embodiment 2 agar oligosaccharides

[0056] (1) Under the conditions of enzymatic hydrolysis temperature of 45°C, enzymatic hydrolysis time of 2 hours, substrate concentration of 0.5%, and enzyme addition of 10U / mL, the effect of pH change on the degree of hydrolysis was studied. When the pH value is 6.5, the degree of hydrolysis is maximum ( Figure 4 ).

[0057] (2) Under the conditions of enzymatic hydrolysis time of 2 hours, substrate concentration of 0.5%, pH value of 6.5, and enzyme addition of 10U / mL, the effect of temperature change on the degree of hydrolysis was studied. When the temperature is 55°C, the degree of hydrolysis is maximum ( Figure 5).

[0058] (3) Under the conditions of enzymolysis temperature of 55℃, substrate concentration of 0.5%, pH value of 6.5, and enzyme addition of 10U / mL, the effect of enzymolysis time on the degree of hydrolysis was studied. When the enzymolysis time is 2h...

Embodiment 3

[0067] The separation and purification of embodiment 3 agar oligosaccharides

[0068] The enzymolysis product obtained by enzymolysis was separated and purified by Sephadex LH-20 gel column. Use distilled water as eluent, flow rate 0.3mL / min, collect 1.2mL in each tube, adopt phenol-sulfuric acid method to measure oligosaccharide content ( Figure 9 ).

[0069] The components were collected, concentrated and then subjected to thin-layer chromatography to determine their components and purity. The new agar-oligosaccharide mixture is well separated by the LH-20 chromatographic column, and the obtained oligosaccharides are: new agarosetrose, new agarohexose, new agaroctaose ( Figure 10 , in the figure 1 is the standard new agarose oligosaccharides, from top to bottom are new agarose, new agarotetraose, new agarosexose, new agarocatose; 2 is the new agarose in the enzymatic hydrolysis product; 3 is New agarose in the hydrolyzate; 4 is new agarose in the hydrolyzate).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com