Composition for relieving xerostomia and preparation method thereof

A composition and symptom technology, applied in the direction of drug combination, medical preparations containing active ingredients, chewing gum, etc., can solve problems such as affecting appetite, affecting digestive system function, and limited ability to dry mouth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

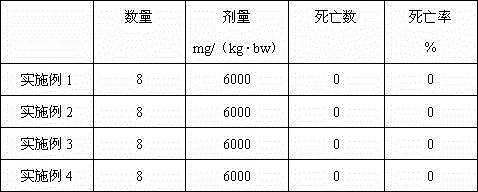

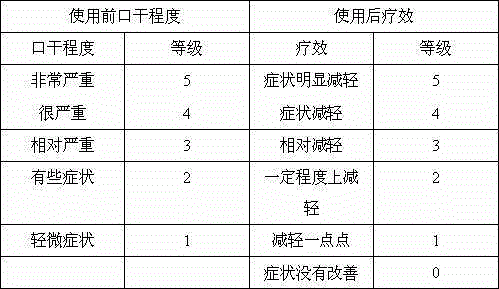

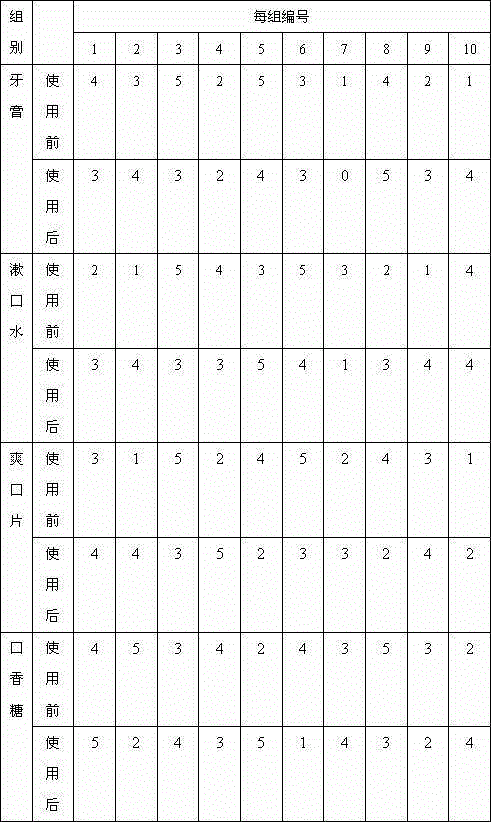

Examples

Embodiment 1

[0013] Add 0.075% hyaluronic acid, 0.05% pullulan, and 0.05% polyglutamic acid in toothpaste to 57.375% deionized water, stir and dissolve, and mix with 16% sorbitol, 14% hydrated silica, and 9% glycerin , 2.2% sodium lauryl sulfate, 1.0% essence, 1.0% cellulose gum, 0.23% sodium pyrophosphate, 0.22% sodium saccharin, and 0.02% sodium benzoate are mixed, sent to a three-in-one vacuum paste machine, high-speed stirring and grinding for 30 Minutes, vacuum degassing; add essence and then stir and grind for 15 minutes to mix well to obtain toothpaste paste, which is packaged after aseptic filling.

Embodiment 2

[0015] Add 0.075% of hyaluronic acid, 0.05% of pullulan, and 0.05% of polyglutamic acid in the mouthwash water into 99.025% deionized water and stir to dissolve, and mix with 0.3% sodium chloride, 0.1% calcium chloride, 0.3% Potassium chloride, 0.15% disodium hydrogen phosphate, and 0.02% sodium benzoate are mixed, stirred at high speed until all substances are dissolved, and packaged after aseptic filling.

Embodiment 3

[0017] According to the ratio of 0.075% hyaluronic acid, 0.05% pullulan, 0.05% polyglutamic acid, 18.0% pullulan, 0.04% xanthan gum, 0.06% locust bean gum and 0.19% carrageenan in refreshing tablets 76.685% deionized water at 70-80°C; then add 0.4% glycerin, 1.5% acesulfame potassium and essence, 3% menthol, and stir for 2-3 hours to obtain a glue; vacuum removes air bubbles; The film-forming liquid is coated on the stainless steel plate with a knife-type film applicator, and the thickness of the film is controlled at 20-30 μm; steam-dried at a drying temperature of 80-90 °C; and the film is removed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com