Copper-based methanol synthesis catalyst and preparation method therefor

A methanol synthesis and catalyst technology, which is applied in the preparation of hydroxyl compounds, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of unrecorded catalyst thermal stability test data, etc., achieve good methanol synthesis activity, reduce production costs, Energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

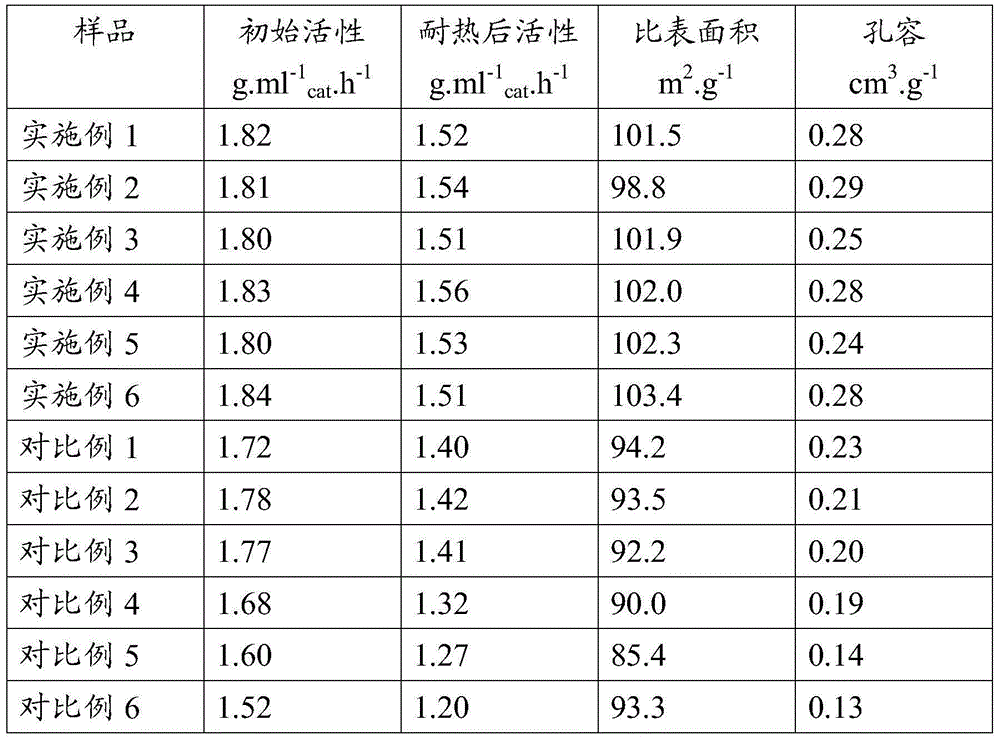

Examples

Embodiment 1

[0027] This example is used to illustrate the copper-based methanol synthesis catalyst of the present invention and its preparation method.

[0028] The catalyst of the present invention is prepared by the following steps:

[0029] (1) Put 1mol / L Cu(NO 3 ) 2 Solution 85mL and 1mol / L Zn(NO 3 ) 2 Put 35mL of the solution in a 200mL beaker and mix at 70~80℃ to obtain a copper-zinc mixed solution;

[0030] (2) Put Na 2 CO 3 And NaHCO 3 Mix and prepare into 300mL aqueous solution, of which CO 3 2- The molar concentration of 0.4mol / L, HCO 3 - The molar concentration of is 0.1mol / L, placed in a 1000mL beaker, can be heated to 70 ~ 80 ℃, to obtain the double precipitant buffer;

[0031] (3) Add the copper-zinc mixed solution to the double precipitating agent buffer at 70-80°C under stirring to a pH value of 7.0-7.5, then heat to 75-85°C and stir for aging for 1 to 1.5h, During the aging process, continue to add the copper-zinc mixed solution to keep the pH at 7.0-7.5 to obtain a copper-zinc s...

Embodiment 2

[0036] This example is used to illustrate the copper-based methanol synthesis catalyst of the present invention and its preparation method.

[0037] The catalyst of the present invention is prepared by the following steps:

[0038] (1) Put 1mol / L Cu(NO 3 ) 2 Solution 85mL and 1mol / L Zn(NO 3 ) 2 Place 30 mL of the solution in a 200 mL beaker and mix at 70-80°C to obtain a copper-zinc mixed solution;

[0039] (2) Put Na 2 CO 3 And NaHCO 3 Mix and prepare into 300mL aqueous solution, of which CO 3 2- The molar concentration of is 0.3mol / L, HCO 3 - The molar concentration of is 0.1mol / L, placed in a 1000mL beaker, can be heated to 70 ~ 80 ℃, to obtain the double precipitant buffer;

[0040] (3) Add the copper-zinc mixed solution to the double precipitating agent buffer at 70-80°C under stirring to a pH value of 7.0-7.5, then heat to 75-85°C and stir for aging for 1 to 1.5h, During the aging process, continue to add the copper-zinc mixed solution to keep the pH at 7.0-7.5 to obtain a coppe...

Embodiment 3

[0045] This example is used to illustrate the copper-based methanol synthesis catalyst of the present invention and its preparation method.

[0046] The catalyst of the present invention is prepared by the following steps:

[0047] (1) Put 1mol / L Cu(NO 3 ) 2 Solution 85mL and 1mol / L Zn(NO 3 ) 2 Place 42 mL of the solution in a 200 mL beaker and mix at 70-80°C to obtain a copper-zinc mixed solution;

[0048] (2) Put Na 2 CO 3 And NaHCO 3 Mix and prepare into 300mL aqueous solution, of which CO 3 2- The molar concentration of 0.5mol / L, HCO 3 - The molar concentration of is 0.1mol / L, placed in a 1000mL beaker, can be heated to 70 ~ 80 ℃, to obtain the double precipitant buffer;

[0049] (3) Add the copper-zinc mixed solution to the double precipitating agent buffer at 70-80°C under stirring to a pH value of 7.0-7.5, then heat to 75-85°C and stir for aging for 1 to 1.5h, During the aging process, continue to add the copper-zinc mixed solution to keep the pH at 7.0-7.5 to obtain a copper-z...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com