Production technology for preparing polyferric chloride coagulant from seamless steel pipe acid-washing waste liquid

A ferric chloride-based, pickling waste liquid technology, applied in the direction of ferric halides, etc., can solve the problems of high energy consumption, and achieve the effects of low energy consumption, complete reaction, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

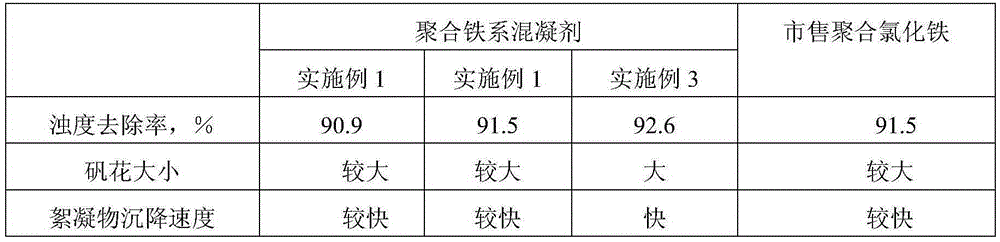

Examples

Embodiment 1

[0028] 4000 kilograms of seamless steel pipe pickling waste liquid was settled and filtered, and pumped into a 6 cubic meter enamel acid-resistant reaction kettle with an acid-resistant pump, and 1000 kilograms of industrial hydrochloric acid (36wt%) was added to adjust the HCl content in the solution to 10wt%. Stir, the control stirring speed is 60 revs / min, add 25 kilograms of nitric acid (accounting for 0.5wt% of reaction liquid total amount) of 36wt% under room temperature as catalyst; Pass into air with 3 liters / min speed, oxidation reaction 6 hours; Add 250 kilograms of trichloroisocyanuric acid (5w% for the total amount of the reaction solution), continued the oxidation reaction for 3 hours, and the ventilation rate of the air was 1440 liters per ton of the reaction solution; after the oxidation reaction finished, add 25 kilograms (accounting for the total amount of the reaction solution 0.5w%) of isopropanolamine is used as a stabilizer, and the reaction solution is fil...

Embodiment 2

[0030] 4,000 kilograms of seamless steel pipe pickling waste liquid was settled and filtered, and pumped into a 6 cubic meter enamel acid-resistant reaction kettle with an acid-resistant pump, and 1,000 kilograms of industrial hydrochloric acid (36wt%) was added to control the HCl content in the solution to 10wt%. Stir, stirring speed control 80 rev / min, add 50 kilograms of 36wt% nitric acid (accounting for 1wt% of reaction solution total amount) under room temperature as catalyst; Feed oxygen with 2 liters / minute speed and carry out oxidation reaction 6 hours; Add 250 kilograms again Trichloroisocyanuric acid (5wt% for the total amount of the reaction solution) continued the oxidation reaction for 3 hours, and the ventilation rate of oxygen was 960 liters per ton of the reaction solution; after the oxidation reaction finished, add 25 kilograms (accounting for 0.5wt% ) isopropanolamine as a stabilizer, and the reaction liquid is filtered and then transferred to an acid-resistan...

Embodiment 3

[0032] 4,000 kilograms of seamless steel pipe pickling waste liquid was settled and filtered, and pumped into a 6 cubic meter enamel acid-resistant reaction kettle with an acid-resistant pump, and 1,000 kilograms of industrial hydrochloric acid (36wt%) was added to control the HCl content in the solution to 10wt%. Stir, stirring speed control 80 revs / min, add 75 kilograms of nitric acid (accounting for 1.5wt% of reaction liquid total amount) of 36wt% under room temperature as catalyst; Feed oxygen with 2 liters / minute speed and carry out oxidation reaction 6 hours; Add 150 One kilogram of trichloroisocyanuric acid (3wt% for the total amount of the reaction solution) continued the oxidation reaction for 3 hours, and the ventilation rate of oxygen was 960 liters per ton of the reaction solution; 25 kilograms (accounting for 0.5wt% of the total reaction solution) of isopropanol were added Amine is used as a stabilizer. After filtering, the reaction solution is transferred to an ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com