Advanced reduction method and device for rapidly removing perfluoro-compounds from water

A perfluorinated compound and water removal technology, applied in the field of water treatment, can solve the problems of low defluorination efficiency, inability to effectively remove PFOA, PFOS, long treatment time, etc., and achieve the effect of cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

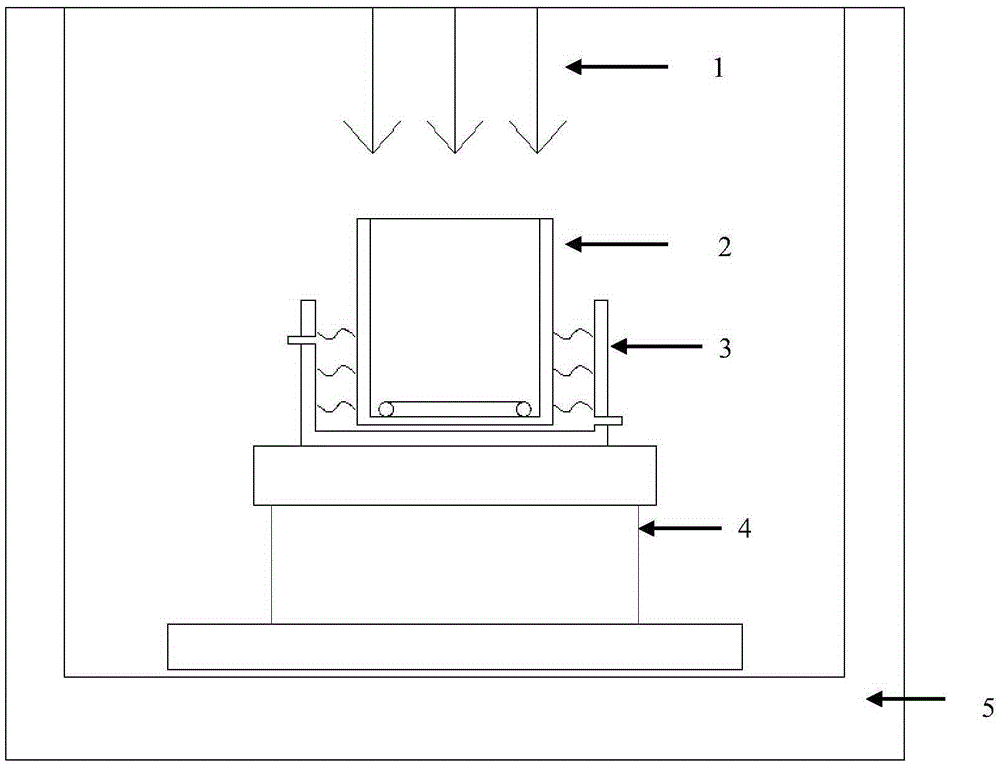

Image

Examples

Embodiment 1

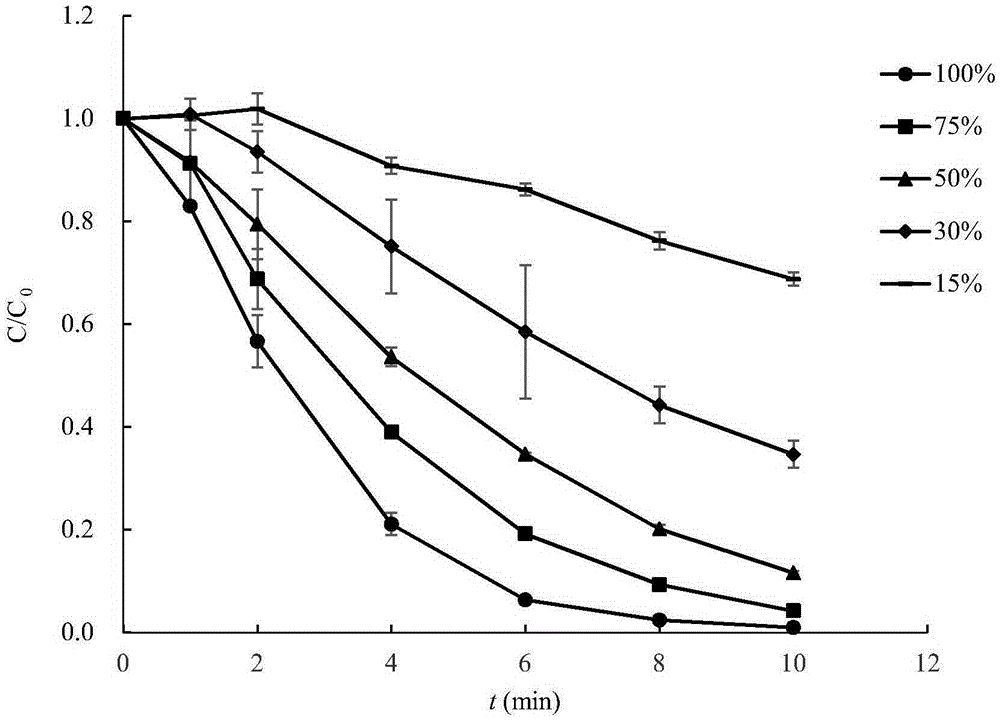

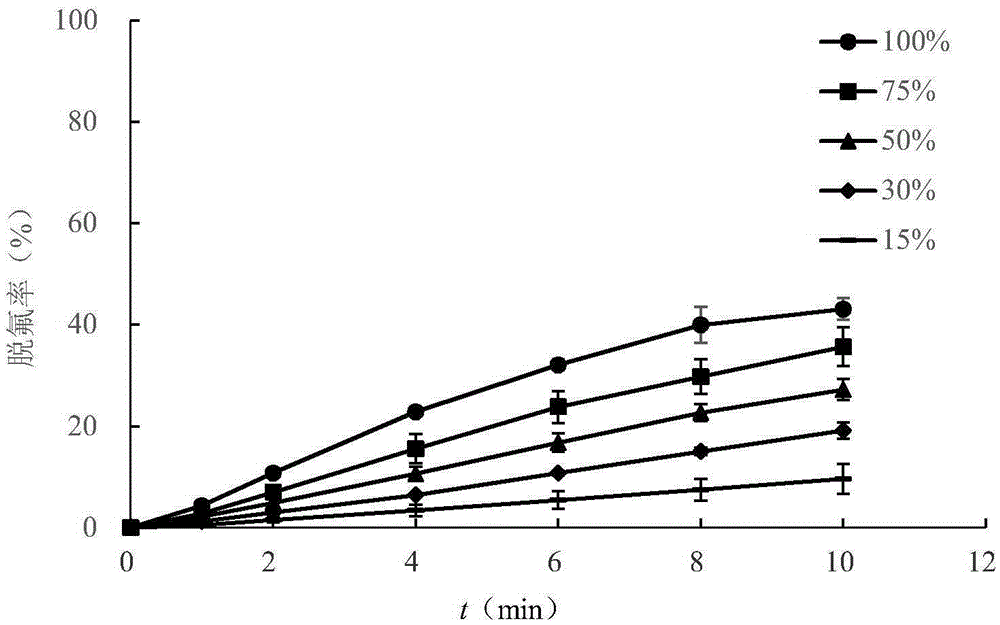

[0042] The concentration of PFOA in water is 20mg / L, the pH of the solution is 4.5, and the water temperature is 25°C. Add 10mM sodium sulfite according to the molar ratio of sodium sulfite to PFOA is 256:1, and the pH of the solution after adding is 9.2. Turn on the magnetic stirrer to mix well. After the UV light is stable, open the slide to start the reaction. According to the needs of the experiment, adjust the light intensity in sequence to 100%I0, 75%I0, 50%I0, 30%I0 and 15%I0, where I0 is the radiation intensity when all the ultraviolet light passes through the grating, and the photometry is adopted by iron potassium oxalate Determination of I0=3.13×10-6einsteincm-2s-1 by method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com