Preparation method for perovskite type solar battery

A solar cell, perovskite-type technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as restricting large-scale application and device instability, and achieve large-scale industrial application prospects, good stability, and mild reaction conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

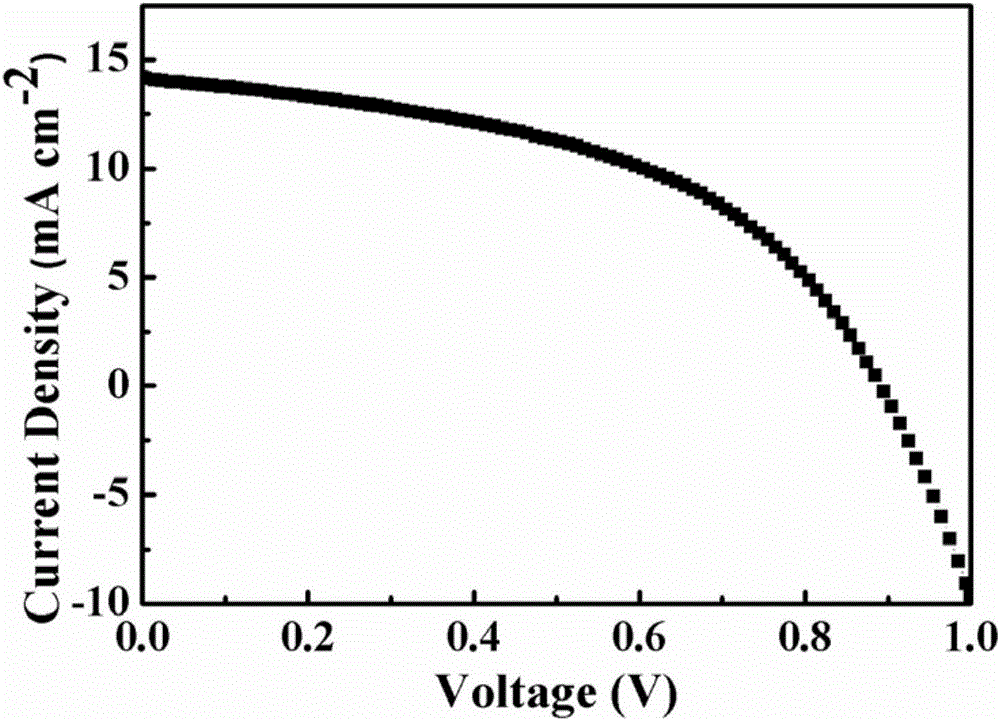

[0015] The invention provides a method for preparing a perovskite type solar cell, which comprises a transparent conductive substrate, a TiO 2 The electron transport layer, the perovskite light absorption layer, the hole transport layer and the metal counter electrode layer, wherein the preparation of the electron transport layer includes the following steps:

[0016] Step a, providing a transparent substrate material with a clean surface, and depositing a dense thin film of titanium dioxide on the surface of the substrate material using atomic layer deposition technology;

[0017] Step b, using molecular layer deposition technology to deposit a titanium-containing organic-inorganic composite film on the titanium dioxide dense film obtained in step a;

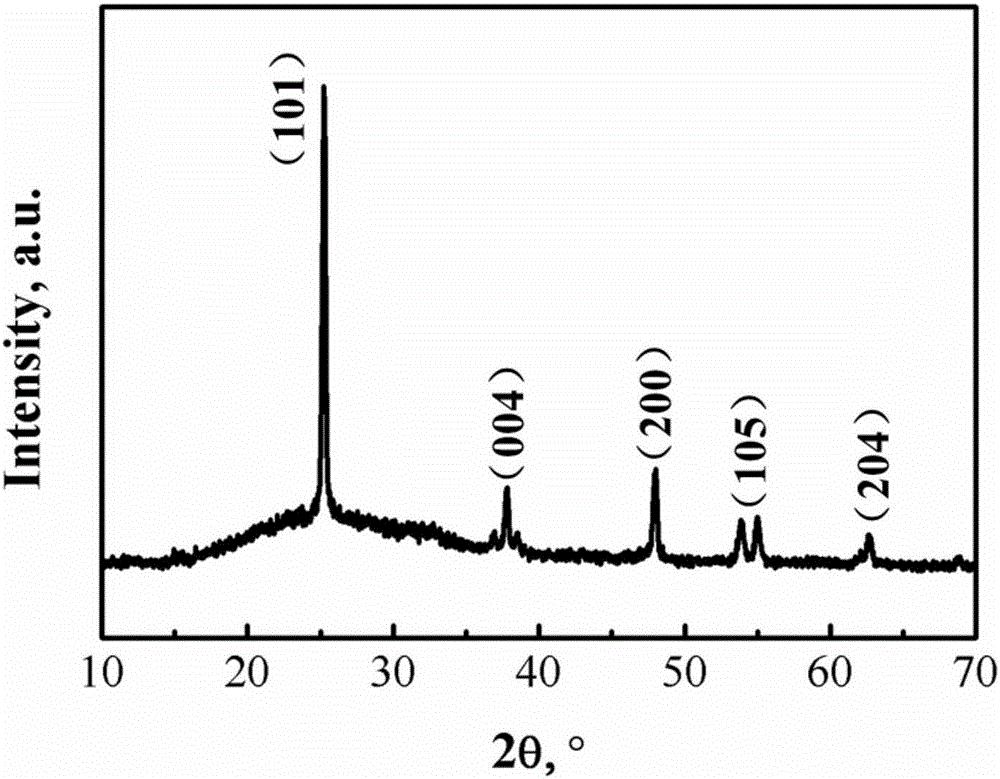

[0018] Step c, annealing the material obtained in step b at 400-600℃ for 0.5-5h to obtain TiO 2 Electron transport layer.

[0019] Preferably, the step a includes ultrasonic cleaning and drying the transparent conductive substrate, and ...

Embodiment 1

[0041] Step a: Ultrasonic cleaning of the FTO conductive glass and drying. After the ultraviolet ozone treatment, it is ready to be used, and a titanium dioxide dense film with a thickness of 120 nm is deposited on the clean FTO conductive glass by using the atomic layer deposition technology. The specific steps include:

[0042] a1. Put the clean surface of the FTO conductive glass into the reaction chamber of the atomic layer deposition equipment at a temperature of 80-200℃, and purge it with 50-100sccm high-purity nitrogen for 5 minutes;

[0043] a2, the TiCl with a purity greater than 97% 4 Heat to 65℃ to form TiCl 4 Steam, and the TiCl 4 The steam is fed into the reaction chamber, the pulse time is 0.05s, the exposure time is 8s, and then purged with high-purity nitrogen, the purge time is 15s;

[0044] a3. Deionized water is fed into the reaction chamber in pulse form, the pulse time is 0.02s, the exposure time is 8s, and then purged with high-purity nitrogen, the purging time ...

Embodiment 2

[0054] Step a: Ultrasonic cleaning of the ITO conductive glass and drying. After ultraviolet ozone treatment, it is ready for use, and a titanium dioxide dense film with a thickness of 300 nm is deposited on the clean ITO conductive glass by atomic layer deposition technology. The specific steps include:

[0055] a1. Put the ITO conductive glass with clean surface into the reaction chamber of the atomic layer deposition equipment at a temperature of 150℃, and purge it with 50sccm high-purity nitrogen for 5 minutes;

[0056] a2. Heat titanium tetraisopropoxide with a purity of more than 97% to 65°C to form titanium tetraisopropoxide vapor, and send the titanium tetraisopropoxide vapor into the reaction chamber in a pulsed form, the pulse time is 0.05s, and the exposure time 8s, then purge with high-purity nitrogen, the purge time is 15s;

[0057] a3. Deionized water is fed into the reaction chamber in pulse form, the pulse time is 0.02s, the exposure time is 8s, and then purged with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com