Biologic modifying method of bran for producing whole wheat flour

A bio-modified, whole-wheat flour technology, applied in the direction of bacteria, application, food science, etc. used in food preparation, can solve the problems of consumer resistance, can not effectively improve the nutritional characteristics and processing characteristics of bran, and achieve extended Excellent storage stability, nutritional properties and processing properties, and flavor improvement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: the biomodification method of the bran that this is used for wholemeal production comprises the steps:

[0034] A, bran pre-treatment: bran crushed to 40-60 mesh sieve; take 100 parts by weight of bran in a bottle, cover and sterilize at 121°C for 20 minutes in an autoclave;

[0035] B, lactic acid bacteria activation: get 1 weight part of commercial lactic acid bacteria powder, inoculate it in the MRS liquid medium, the inoculum size is 1:500 (w / v), then carry out activation cultivation under the condition of 36~38 ℃ for 16h at the temperature, to In the middle and late stages of the logarithmic growth phase, the activated lactic acid bacteria liquid is obtained. The bacterial solution was centrifuged, and the supernatant was discarded. The cell pellet was resuspended to the original volume with distilled water to obtain the lactic acid bacteria suspension;

[0036] C, bran fermentation: get 100 parts by volume (mL) of the lactic acid bacteria suspensio...

Embodiment 2

[0042] Embodiment 2: the biomodification method of the bran that this is used for wholemeal production comprises the steps:

[0043] A, bran pretreatment: same as embodiment 1;

[0044] B, lactic acid bacteria activation: same as embodiment 1;

[0045] C, bran fermentation: get 1.25 parts by weight (g) of yeast dry powder and be dissolved in 100 parts by volume (mL) of distilled water, join in 100 parts by weight (g) of sterilized bran, stir at a temperature of 37 Cultivate for 24 hours under the condition of ℃;

[0046] D, bran drying: same as embodiment 1;

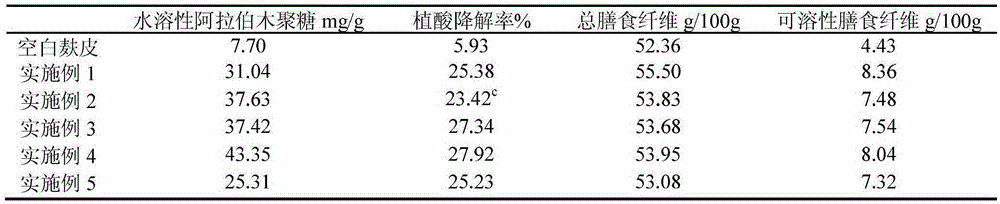

[0047] Physical and chemical indicators: water-soluble arabinoxylan, phytic acid degradation rate, total dietary fiber, soluble dietary fiber (as shown in Table 1).

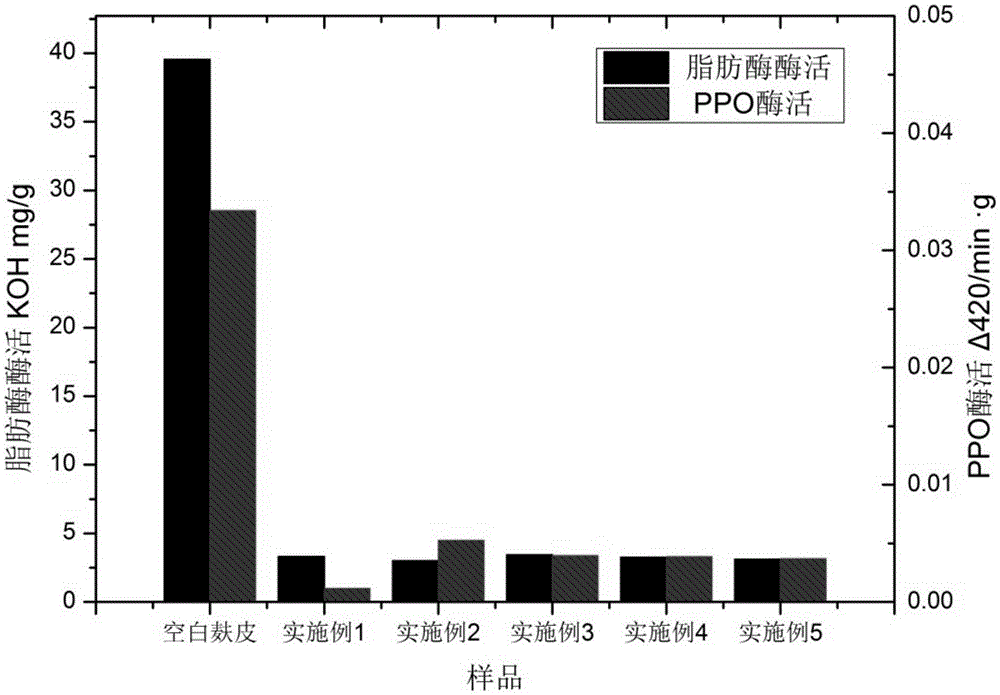

[0048] Enzymatic properties: lipase, polyphenol oxidase (such as figure 1 shown).

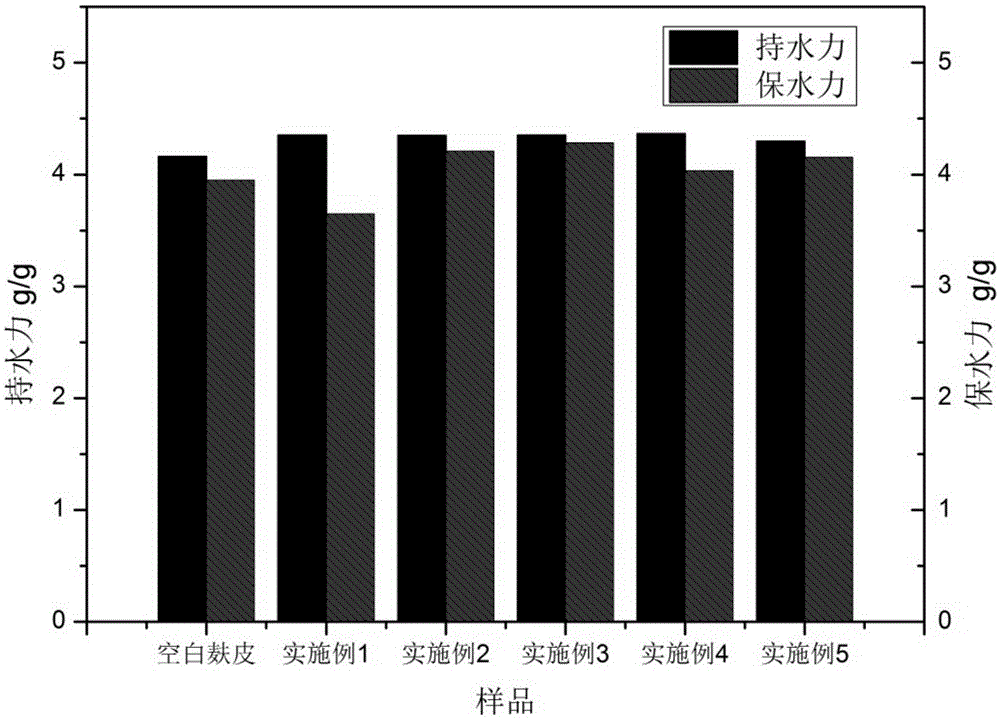

[0049] Hydration characteristics: water holding capacity, water retention capacity (such as figure 2 shown).

[0050] According to the invention: the water-soluble a...

Embodiment 3

[0051] Embodiment 3: the biomodification method of the bran that this is used for wholemeal production comprises the steps:

[0052] A, bran pretreatment: same as embodiment 1;

[0053] B, lactic acid bacteria activation: same as embodiment 1;

[0054] C, bran fermentation: get 1.25 parts by weight (g) yeast dry powder and dissolve in 100 parts by volume (mL) of the activated lactic acid bacteria suspension, join in 100 parts by weight (g) of sterilized bran, stir Incubate at 37°C for 24 hours after uniformity;

[0055] D, bran drying: same as embodiment 1;

[0056] Physical and chemical indicators: water-soluble arabinoxylan, phytic acid degradation rate, total dietary fiber, soluble dietary fiber (as shown in Table 1).

[0057] Enzymatic properties: lipase, polyphenol oxidase (such as figure 1 shown).

[0058] Hydration characteristics: water holding capacity, water retention capacity (such as figure 2 shown).

[0059] According to the invention: the water-soluble ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com