Method for preparing nanometer platinum nickel/titanium dioxide nanotube electrode by cyclic voltammeter electrodeposition

A cyclic voltammetry, titanium dioxide technology, applied in electrolytic coatings, surface reaction electrolytic coatings, coatings, etc., can solve the problems of serious hydrogen evolution and concentration polarization, CO poisoning of pure platinum electrodes, and difficult platinum-nickel co-deposition, etc. Achieve the effect of reducing hydrogen evolution and concentration polarization, improving anti-toxicity and reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the examples, but the present invention is not limited to the following examples.

[0027] Titanium sheet pretreatment, after polishing the titanium sheet (purity 99.6%) with acetone and alcohol for 10 minutes, ultrasonically remove the surface oil, then pickle to remove the oxide layer on the surface, wash it and set it aside. The following implementation examples are all the same.

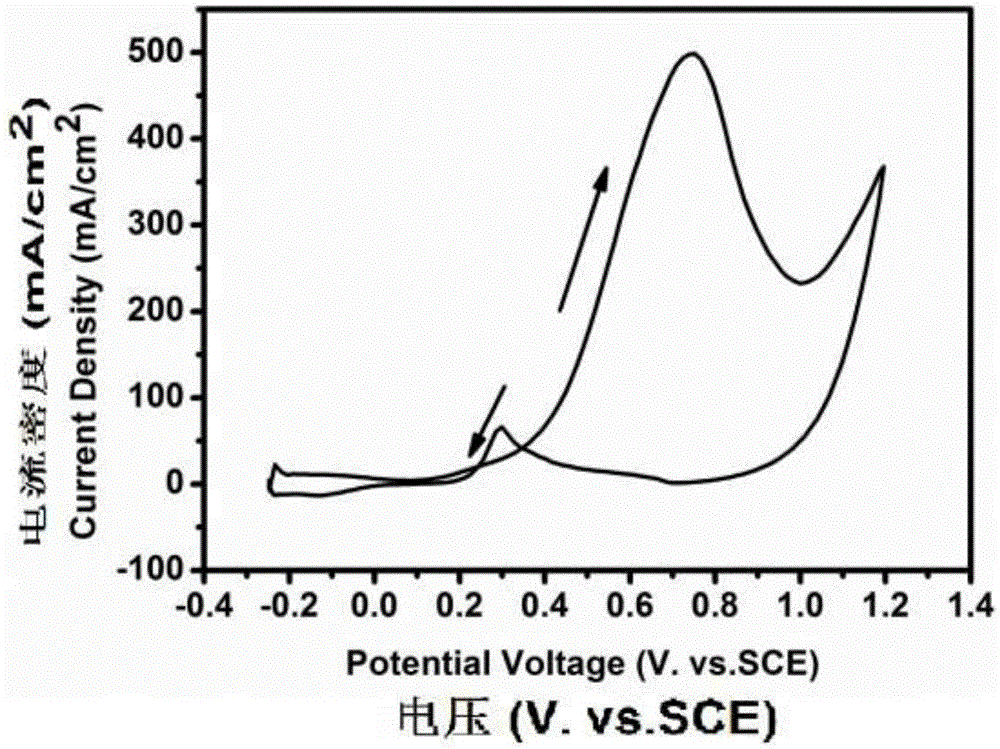

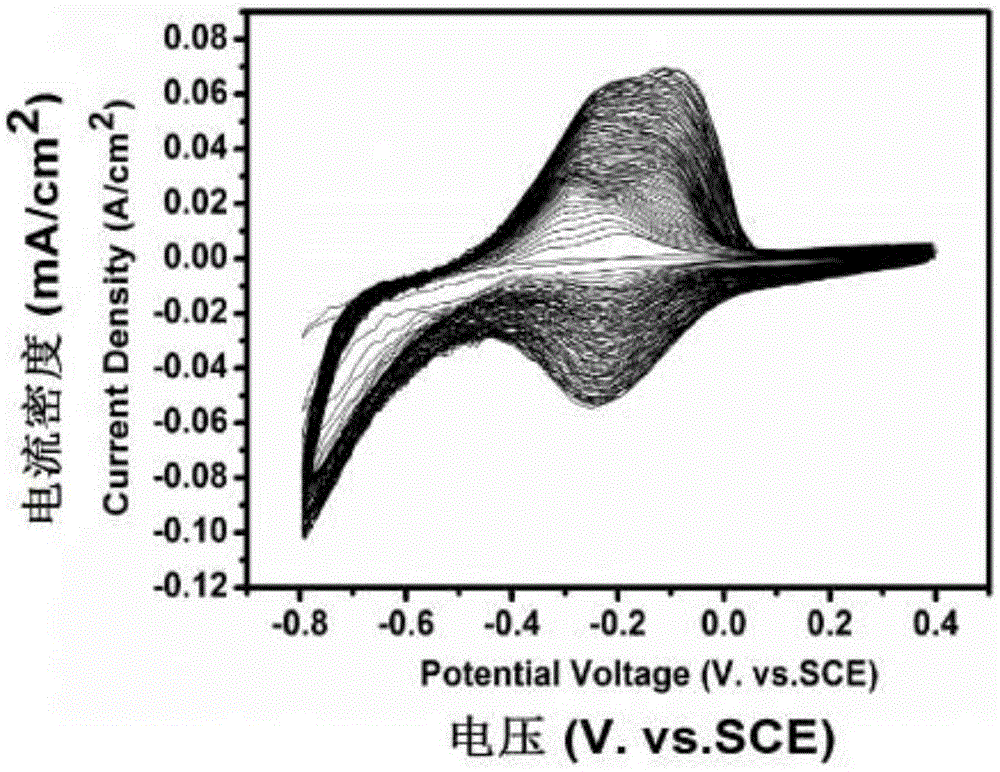

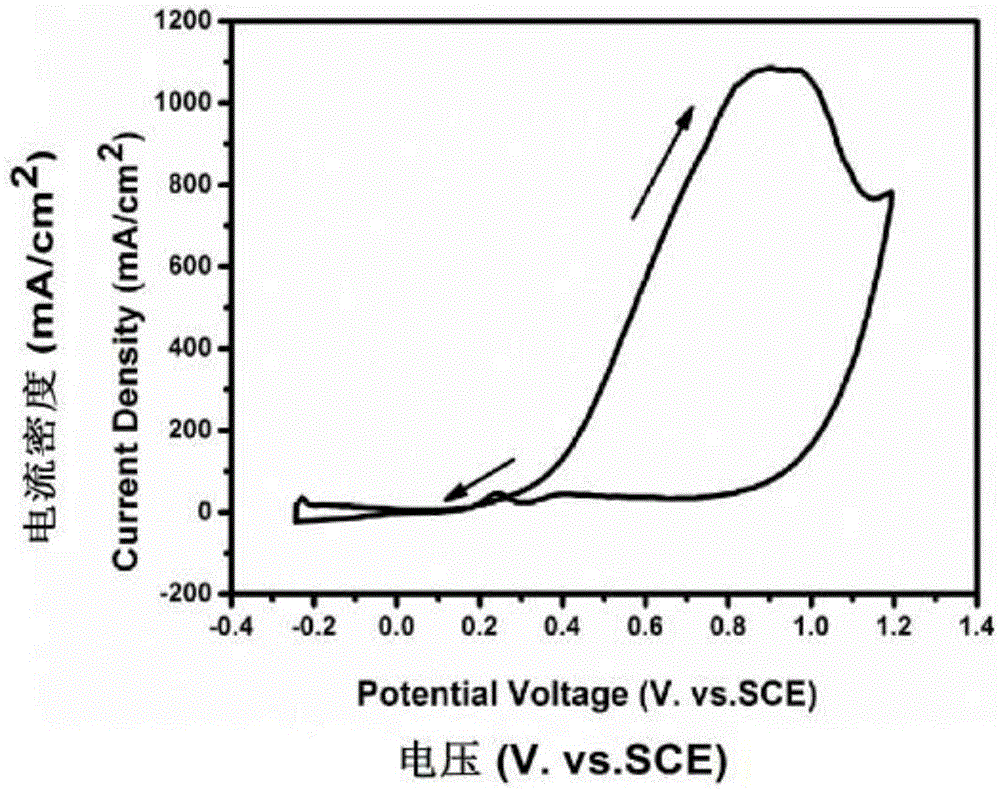

[0028] Example 1. Put the pretreated titanium sheet into 1g / LNH 4 HF 2 , 100ml / LH 2 O in ethylene glycol solution for anodic oxidation to prepare titanium oxide nanotubes. After heat treatment, put them into an electrolyte containing 4.0mM chloroplatinic acid + 4.0mM nickel sulfate. The scanning speed is 50mV / s, and the voltage scanning range is -0.5V ~1V, and the scanning period is 30 times. The test of the prepared electrode to catalyze methanol is: put the electrode into 0.5MH 2 SO 4 +1.0MCH 3 In the soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com