Water hydrogen power mining machine without tail gas discharging

A technology for exhaust emission and mining machines, which is applied in the field of power mining machines, can solve problems such as difficulty in popularization, poor battery life, slow start of hybrid vehicles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

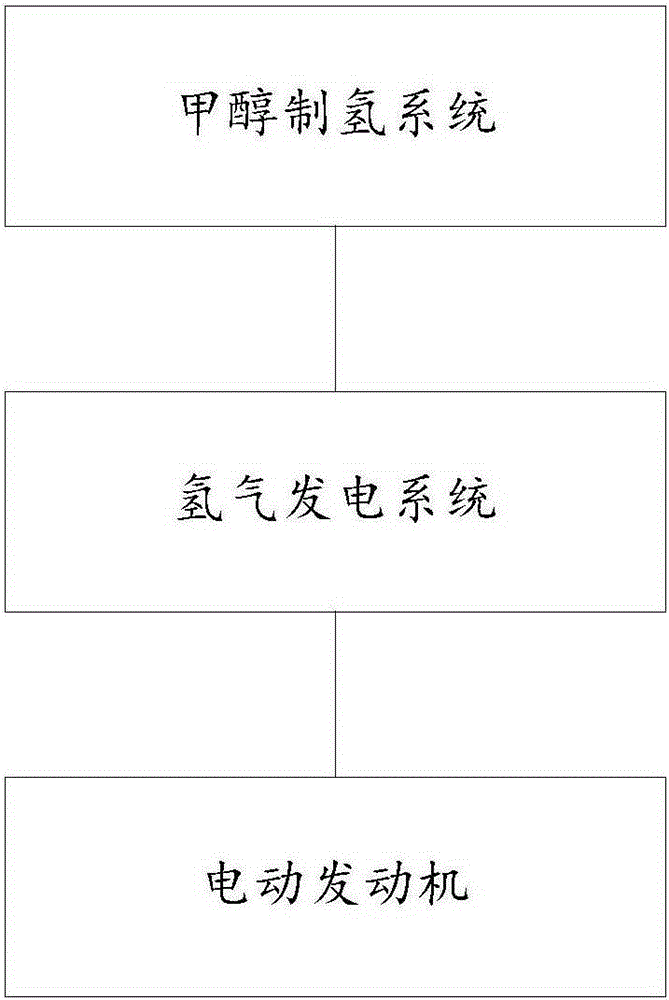

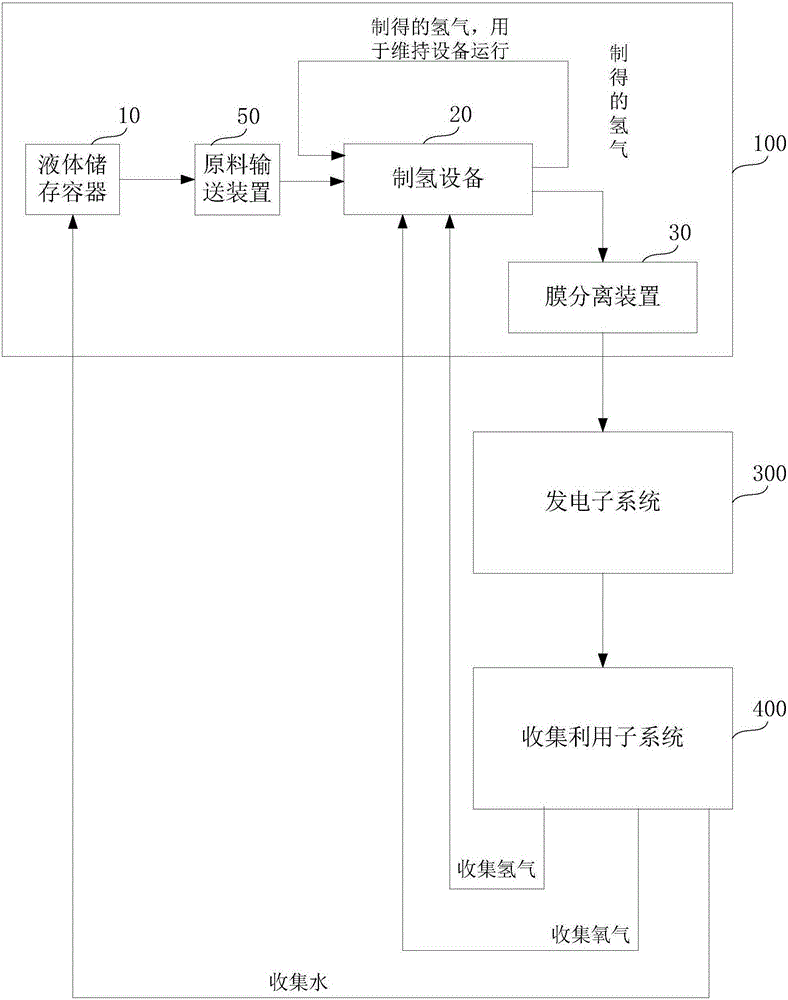

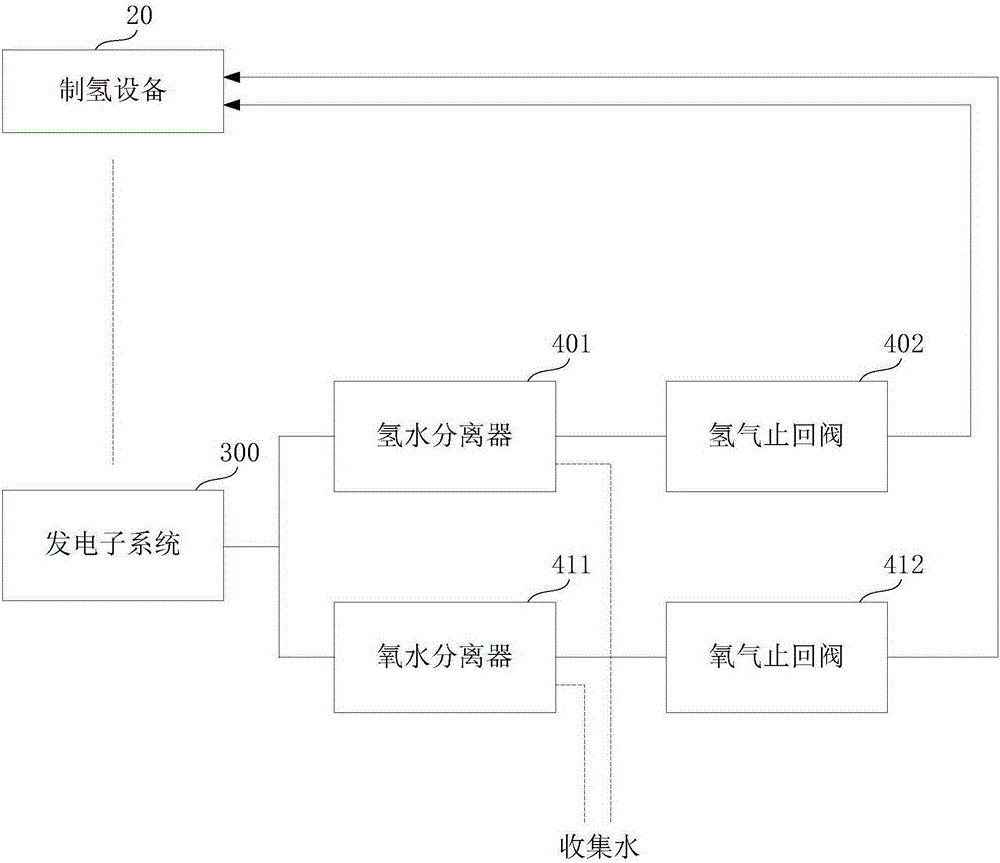

[0069] see figure 1 , the present invention discloses a water-hydrogen power mining machine, the mining machine includes: a mining machine body, a methanol hydrogen production system, a hydrogen power generation system, an electric motor, a methanol hydrogen production system, a hydrogen power generation system, and an electric motor arranged on the mining machine Inside the main body; the methanol hydrogen production system, the hydrogen power generation system, and the electric motor are connected in sequence. The methanol-to-hydrogen system utilizes steam reforming of methanol to produce hydrogen. The hydrogen passes through a palladium-silver alloy-coated membrane separation device to obtain high-purity hydrogen. The obtained hydrogen generates electricity through a hydrogen power generation system, and the generated electric energy is used for the operation of an electric motor.

[0070] The excavator body includes a cutting part and a traction part; the main function of ...

Embodiment 2

[0111] A water-hydrogen power mining machine, the mining machine includes: a mining machine body, a methanol hydrogen production system, a hydrogen power generation system, an electric motor, the methanol hydrogen production system, a hydrogen power generation system, and an electric motor are arranged in the mining machine body, The hydrogen system, the hydrogen power generation system, and the electric motor are connected in sequence; the methanol hydrogen production system uses methanol steam reforming to prepare hydrogen, and the hydrogen is obtained through a membrane separation device coated with palladium-silver alloy to obtain high-purity hydrogen, and the obtained hydrogen is generated through hydrogen. The system generates electricity, and the electricity generated is used to work the electric motor.

[0112] The methanol hydrogen production system includes a storage container, the storage container is provided with an isolation mechanism and an isolation mechanism ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com