Ethylene-vinyl alcohol copolymer-containing resin composition, film, laminate, packaging material, vacuum heat-insulating body, film production method, and laminate production method

A resin composition, vinyl alcohol technology, applied in the direction of metal material coating process, packaging, wrapping paper, etc., can solve the problems of pinhole suppression, insufficient lamination processability, unable to fully suppress, unable to reduce pinholes, etc., Achieves the effects of excellent vapor deposition defect suppression, excellent adhesion strength of vapor deposition layers, and improved appearance characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0308] (Synthesis of water-containing EVOH pellets)

[0309] Using a 250 L pressurized reaction tank, polymerization was carried out under the following conditions to synthesize an ethylene-vinyl acetate copolymer.

[0310] (Feeding amount)

[0311] Vinyl acetate: 83.0kg

[0312] Methanol: 17.4kg

[0313] 2,2'-Azobisisobutyronitrile: 66.4g

[0314] (aggregation condition)

[0315] Polymerization temperature: 60°C

[0316] Polymerization tank ethylene pressure: 3.9MPa

[0317] Polymerization time: 3.5 hours

[0318] The polymerization rate of vinyl acetate in the above polymerization was 36%. After adding sorbic acid to the obtained copolymerization reaction liquid, it was supplied to a distillation column, and unreacted vinyl acetate was removed from the top of the column by introducing methanol vapor from the lower part of the column to obtain a 41% by mass methanol solution of an ethylene-vinyl acetate copolymer. The ethylene content of this ethylene-vinyl acetate c...

Embodiment 2~117 and comparative example 1~22

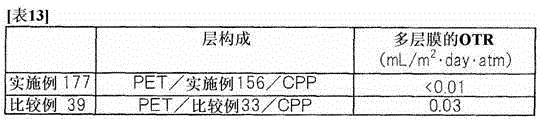

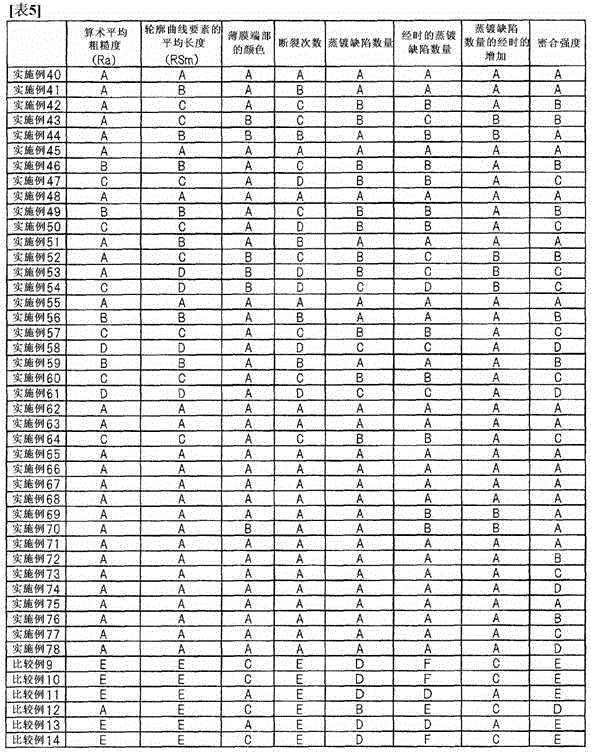

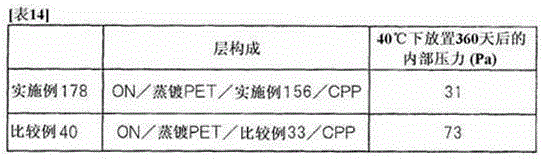

[0328] In Example 1, the types and amounts of the inorganic particles (B) and the aliphatic carbonyl compound (C), and the thickness of the vapor-deposited layer were changed as shown in Tables 1 to 3. In the same manner, a dry EVOH resin composition, a film, and a laminate (a laminate having an aluminum vapor-deposited layer) were obtained. The evaluation results of the obtained EVOH resin compositions, films, and laminates are shown in Tables 4 to 6.

[0329]

[0330]

[0331]

[0332]

[0333]

[0334]

[0335] From the results of Tables 4 to 6, it is clear that the films of Examples are excellent in appearance characteristics and film fracture resistance. In addition, among the laminated bodies, the laminated body obtained by vapor-depositing the metal on the film has few vapor-deposition defects, and has excellent adhesion strength between the metal vapor-deposited layer and the EVOH film layer. On the other hand, in the comparative example in which the...

Synthetic example 1

[0338] Using a 250 L pressurized reaction tank, polymerization of an ethylene-vinyl acetate copolymer was implemented on the following conditions.

[0339] (Feeding amount)

[0340] Vinyl acetate 91.2kg

[0341] Methanol 31.9kg

[0342] 2,2'-azobisisobutyronitrile concentration 2.0g / L (methanol solvent)

[0343] The supply rate of 2,2'-azobisisobutyronitrile is 828mL / hr.

[0344] (aggregation condition)

[0345] Polymerization temperature 60°C

[0346] Polymerization tank ethylene pressure 3.59MPa

[0347] Polymerization time 5.0 hours

[0348] The polymerization ratio of vinyl acetate in the obtained copolymer was about 40%. After adding sorbic acid to this copolymerization reaction solution, it was supplied to a distillation column, and unreacted vinyl acetate was removed from the top of the column by introducing methanol vapor from the lower part of the column to obtain a 41% methanol solution of an ethylene-vinyl acetate copolymer. The ethylene content of this ethy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com