A kind of preparation method of highly elastic anti-wrinkle artificial blood vessel

An artificial blood vessel and high elasticity technology, applied in the field of biomedical engineering, can solve the problems of limited elasticity of blood vessels, high weaving density of warp and weft, and easy blockage of blood vessels, so as to improve the ability to overcome deformation, high elasticity and compliance, and fatigue resistance clinical The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

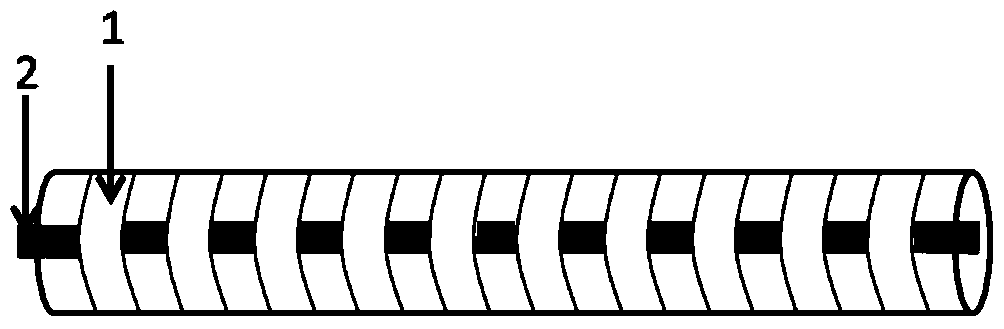

[0039] The preparation process of the highly elastic anti-wrinkle artificial blood vessel is as follows:

[0040] 1. A preparation method for a highly elastic anti-wrinkle artificial blood vessel, characterized in that: the preparation method for the highly elastic anti-wrinkle artificial blood vessel is carried out in the following steps:

[0041] a. Solution preparation

[0042] Dissolve polycaprolactone and polyurethane with a mass ratio of 10:90-30:70 in N,N-dimethylamide solvent, stir until completely dissolved, and prepare a solid mass fraction of 10-20% solution, placing the solution in an environment with a vacuum degree of 0.05-0.1 MPa for 2-5 hours to obtain a defoaming solution.

[0043] Wherein, described polyurethane is a kind of in CorthaneTM or Bionate® 80A or Bionate® 90A.

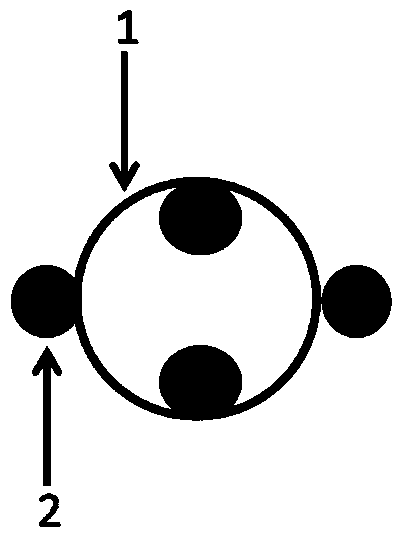

[0044] b. Fabrication of bellows structure

[0045] Add the defoaming solution prepared in step a into a container with a metering pump, extrude through the metering pump, the hole diame...

Embodiment 1

[0056] a Take by weighing 27g polyurethane (CorethaneTM) and 3g polycaprolactone on precision electronic balance, fully dissolve in 170gN, in the N-dimethylamide, obtain the solution that concentration is 15%, the mass ratio of polyurethane and polycaprolactone The ratio is 90:10, and the solution is placed in an environment with a vacuum degree of 0.05MPa for 3 hours to obtain a defoaming solution.

[0057] b. Add the prepared defoaming solution into a container with a metering pump. The aperture of the liquid outlet of the container is 0.3mm. : carry out pre-coagulation in the coagulation bath of 20 mass ratio configurations, phase transition and phase exchange occur in the deaeration solution in the coagulation bath, and gradually become semi-cured filaments, the pre-coagulation length of the deaeration solution in the coagulation bath is 30cm, pre-coagulation The coagulation time is 10s, and the semi-cured filament is drawn to a cylinder mold with a rotation speed of 15 rp...

Embodiment 2

[0060] a Take by weighing 27g polyurethane (CorethaneTM) and 3g polycaprolactone on precision electronic balance, fully dissolve in 170gN, in the N-dimethylamide, obtain the solution that concentration is 15%, the mass ratio of polyurethane and polycaprolactone The ratio is 90:10, and the solution is placed in an environment with a vacuum degree of 0.05MPa for 3 hours to obtain a defoaming solution.

[0061] b. Add the prepared defoaming solution into a container with a metering pump. The aperture of the liquid outlet of the container is 0.3mm. : carry out pre-coagulation in the coagulation bath of 20 mass ratio configurations, phase transition and phase exchange occur in the deaeration solution in the coagulation bath, gradually become semi-cured filaments, the pre-coagulation length of the deaeration solution in the coagulation bath is 40cm, pre-coagulation The coagulation time is 15s, and the semi-cured filament is drawn to a cylindrical mold with a rotation speed of 35 rpm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com