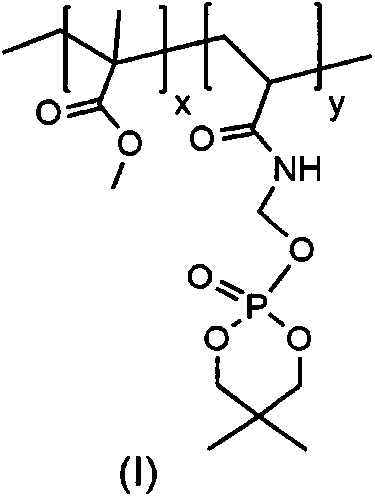

Highly-transparent flame-retardant modified organic glass and preparation method thereof

A plexiglass and transparent technology, applied in the field of flame retardant modified plexiglass and its preparation, can solve the problems of increasing the production cost of flame retardants, affecting the application of modified polymers, etc., achieving low production cost and being conducive to industrial application Promotion, good effect of flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

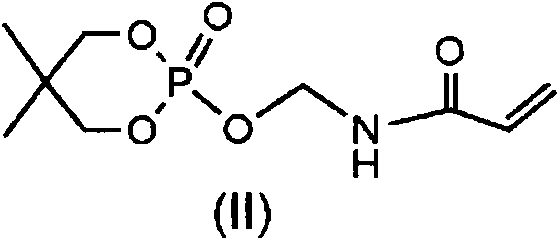

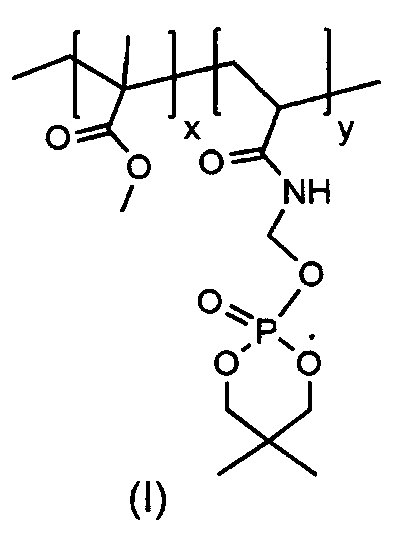

[0031] (1) Add 19.37g (0.097mol) 2-oxo-2-chloro-5,5-dimethyl-1,3,2-dioxaphosphorinane, 10.63g (0.105mol) ) N-methylolacrylamide, 100g methyl methacrylate and 0.15g hydroquinone, feed nitrogen, stir and slowly raise the temperature to 110°C, and react for 4 hours to obtain a reactive flame retardant containing phosphorus nitrogen system agent and methyl methacrylate mixture;

[0032] (2) Cool the mixed solution obtained in step (1) to 90° C., add 0.8 g of cumene hydroperoxide, and stir for 0.5 hours to complete the prepolymerization;

[0033] (3) Inject the prepolymer prepared in step (2) into a mold and exhaust it, polymerize at a low temperature of 40° C. for 24 hours, and obtain a flame-retardant modified organic glass after demolding. The limiting oxygen index (LOI) of the obtained flame-retardant modified organic glass is 30.7%, and the light transmittance is 89.1%.

Embodiment 2

[0035] The preparation operation method of flame-retardant modified plexiglass and the amount of methyl methacrylate are the same as in Example 1, except that:

[0036] In step (1), the molar ratio of 2-oxo-2-chloro-5,5-dimethyl-1,3,2-dioxaphosphorinane to N-methylolacrylamide is 1:1.1 , The total mass of 2-oxo-2-chloro-5,5-dimethyl-1,3,2-dioxaphosphorinane and N-methylolacrylamide is the mass of methyl methacrylate 15%, the polymerization inhibitor is methyl hydroquinone, the mass is 0.03% of methyl methacrylate, the reaction temperature is 50°C, and the reaction time is 8 hours;

[0037] In the step (2), the prepolymerization temperature is 70° C., the initiator is benzoyl peroxide, and the initiator quality is 1% of the quality of methyl methacrylate;

[0038]The low-temperature polymerization temperature in step (3) is 50° C., and the time is 18 hours. The LOI of the obtained flame-retardant modified organic glass was 25.1%, the light transmittance was 91.4%, and the pre...

Embodiment 3

[0040] The preparation operation method of flame-retardant modified plexiglass and the amount of methyl methacrylate are the same as in Example 1, except that:

[0041] In step (1), the molar ratio of 2-oxo-2-chloro-5,5-dimethyl-1,3,2-dioxaphosphorinane to N-methylolacrylamide is 1: 1.2 , The total mass of 2-oxo-2-chloro-5,5-dimethyl-1,3,2-dioxaphosphorinane and N-methylolacrylamide is the mass of methyl methacrylate 5%, the polymerization inhibitor is p-benzoquinone, the mass is 0.06% of the mass of methyl methacrylate, the reaction temperature is 60°C, and the reaction time is 7 hours;

[0042] In the step (2), the prepolymerization temperature is 80° C., the initiator is tert-butyl hydroperoxide, the quality is 0.5% of the quality of methyl methacrylate, and the prepolymerization time is 1 hour;

[0043] In step (3), the low-temperature polymerization temperature is 60° C., and the time is 18 hours. The LOI of the obtained flame-retardant modified organic glass is 22.4%, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com