Regenerated polyethylene-graphene composite conducting material and preparation method thereof

A composite technology of recycled polyethylene and graphene, which is applied in the field of polymer materials, can solve the problems of reduced comprehensive performance, increased specific gravity, and large surface energy of products, and achieves the effect of maintaining mechanical properties, good mechanical properties, and improving electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

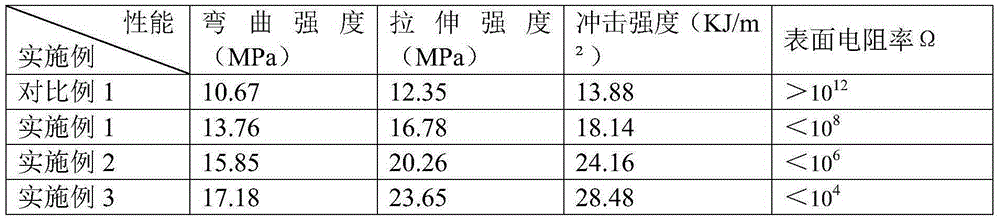

Examples

Embodiment 1

[0030] Implementation process:

[0031] In parts by weight, 1 part by weight of graphene microflakes with a thickness of 2-40nm is placed in a kneader, the liquid dispersant white oil is diluted 3 times with dehydrated alcohol, and gently sprayed on the graphene microchips, and then Cover the kneader, add 50 parts by weight of polyethylene, 3 parts by weight of EVA, 0.1 parts by weight of antioxidant 1010 and 0.2 parts by weight of antioxidant 168, and stir for 15-30 minutes. The mixed materials are fed into a twin-screw extruder, and the processing temperature is controlled at 140°C-225°C for extrusion and granulation to obtain master batches.

[0032] The above-mentioned gained masterbatch and remaining 50 weight parts polyethylene, the maleic anhydride grafted polyethylene compatibilizer of 3 weight parts, the zinc stearate of 05 weight parts, the polyethylene wax of 0.5 weight part and 10 weight parts talcum powder filler, put them together in a high-speed mixer fo...

Embodiment 2

[0035] Implementation process:

[0036] In parts by weight, 2.5 parts by weight of graphene microflakes with a thickness of 2-40nm are placed in a kneader, the liquid dispersant white oil is diluted 3 times with dehydrated alcohol, and gently sprayed on the graphene microchips, and then Cover the kneader, add 50 parts by weight of polyethylene, 3 parts by weight of EVA, 0.1 parts by weight of antioxidant 1010 and 0.2 parts by weight of antioxidant 168, and stir for 15-30 minutes. The mixed materials are fed into a twin-screw extruder, and the processing temperature is controlled at 140°C-225°C for extrusion and granulation to obtain master batches.

[0037] The above-mentioned gained masterbatch and remaining 50 weight parts polyethylene, the maleic anhydride grafted polyethylene compatibilizer of 3 weight parts, the zinc stearate of 05 weight parts, the polyethylene wax of 0.5 weight part and 10 weight parts talcum powder filler, put them together in a high-speed mixe...

Embodiment 3

10

[0041] Implementation process:

[0042]In parts by weight, 5 parts by weight of graphene microsheets with a thickness of 2-40nm are placed in a kneader, the liquid dispersant white oil is diluted 3 times with absolute ethanol, and gently sprayed on the graphene microsheets, and then Cover the kneader, add 50 parts by weight of polyethylene, 3 parts by weight of EVA, 0.1 parts by weight of antioxidant 1010 and 0.2 parts by weight of antioxidant 168, and stir for 15-30 minutes. The mixed materials are fed into a twin-screw extruder, and the processing temperature is controlled at 140°C-225°C for extrusion and granulation to obtain master batches.

[0043] The above-mentioned gained masterbatch and remaining 50 weight parts polyethylene, the maleic anhydride grafted polyethylene compatibilizer of 3 weight parts, the zinc stearate of 05 weight parts, the polyethylene wax of 0.5 weight part and 10 weight parts talcum powder filler, put them together in a high-speed m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com