P-phenyl di(3,4-dicyano phenyl) thioether polymeric iron phthalocyanine and preparation method and application thereof

A technology of dicyanophenyl and dicyanobenzene, which is applied in the field of synthesis of a p-phenylene disulfide polymerized iron phthalocyanine and its preparation, can solve the problems of high production cost, poor activity and stability of noble metal nanocatalysts, etc. Achieve the effect of excellent catalytic activity and stability, simple synthesis method and wide application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Disperse 0.5g of graphite and 0.5g of sodium nitrate in 42.32g of concentrated sulfuric acid, slowly add 3g of potassium permanganate under mechanical stirring at 0°C; stir in a water bath at 35°C for 1 hour; add 40g of water, After stirring for 30 minutes, add 100g of water and 4.44g of 30% hydrogen peroxide (H 2 o 2 ) after suction filtration, washing with water and centrifugation until the centrifuged water is neutral, and vacuum drying at 45° C. for 12 hours to obtain graphene oxide.

Embodiment 2

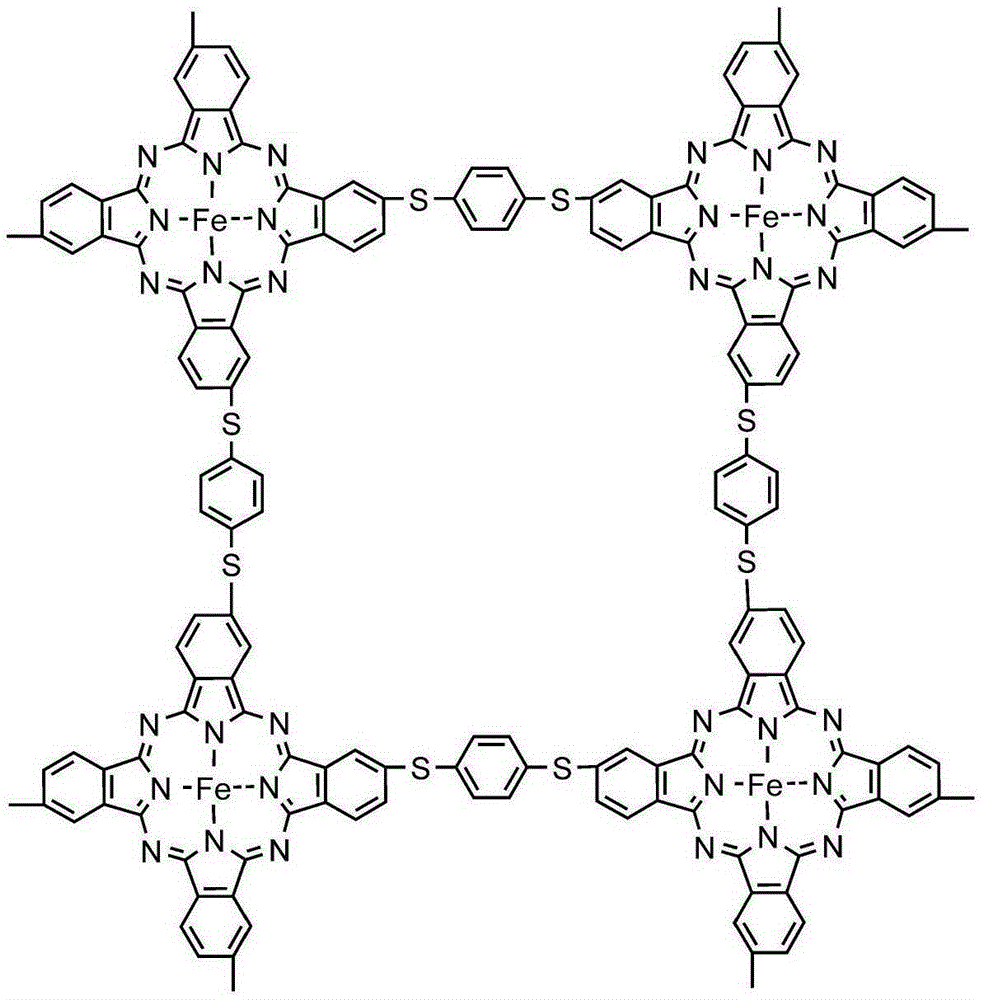

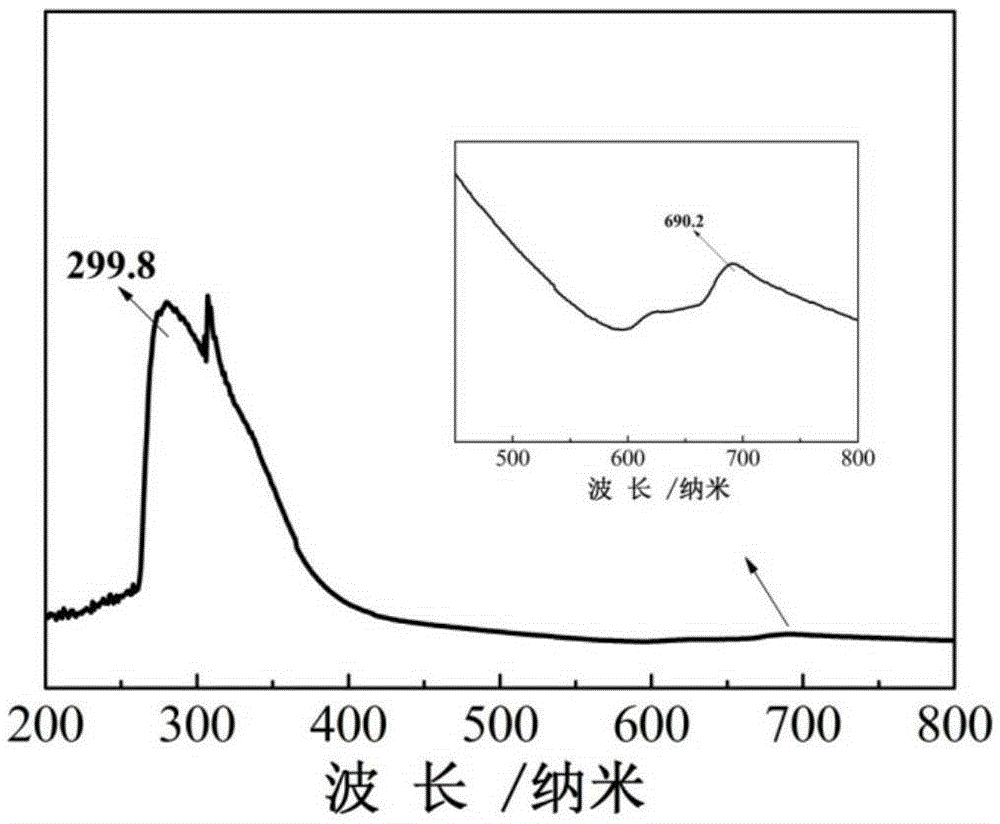

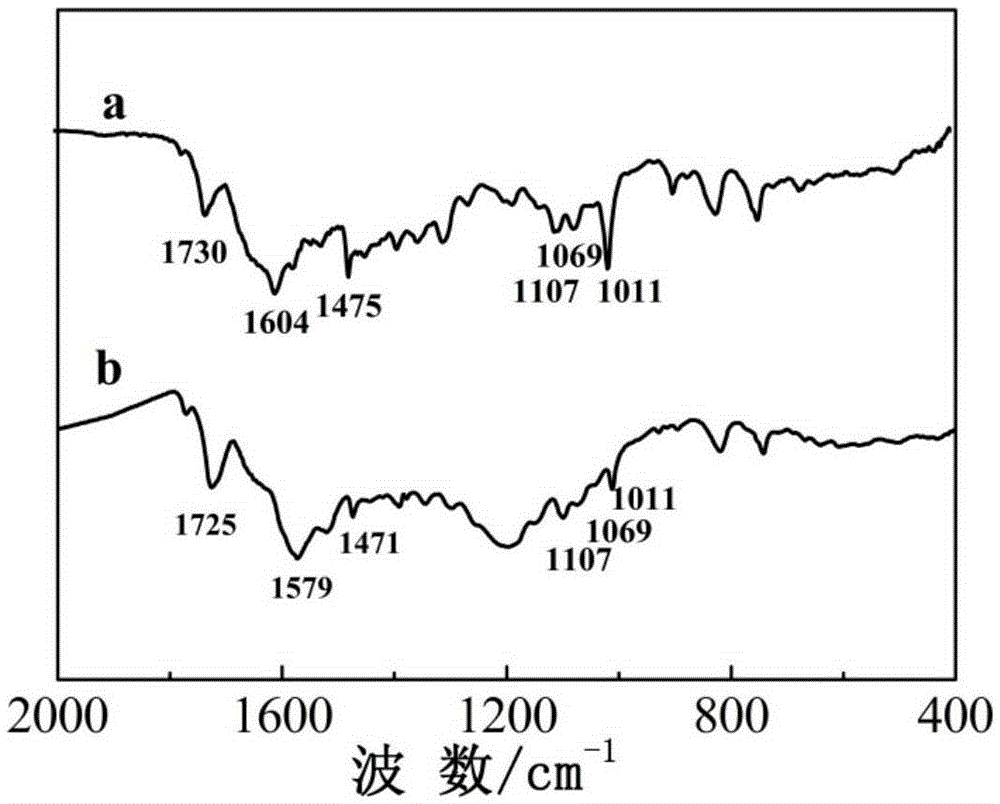

[0039] in N 2 Under gas protection, 1 mmol of hydroquinone, 2 mmol of 4-nitrophthalonitrile, 2 mmol of anhydrous potassium carbonate and 259.2 mmol of N,N-dimethylformamide (DMF) were reacted at 55°C for 6 hours with magnetic stirring. Pour into deionized water after being cooled to room temperature, filter, obtain the powdered terephthalate (3,4-dicyanophenyl) sulfide monomer; ) sulfide monomer was washed 3 times with ethanol, and dried under vacuum at 50°C; 2 4H 2 O), 3.345mmol DBU and 184.9mmol n-pentanol reacted at 160°C with magnetic stirring for 6 hours, cooled naturally to room temperature after the reaction, added three times of water and filtered to obtain p-phthalenic di(3,4-dicyanophenyl)sulfur The crude product of ether polymerized iron phthalocyanine; the crude product of terephthalocyanine (3,4-dicyanophenyl) sulfide polymerized iron phthalocyanine is washed with DMF, water and ethanol to neutrality respectively, and after drying, terephthalo(3 , 4-dicyanophen...

Embodiment 3

[0041] Disperse the graphene oxide of 10mg embodiment 1 in 14.2125gDMF2, add the PTFePPc of 30mg embodiment 2, in 160 ℃ hydrothermal reaction 12 hours, obtain the graphene oxide composite material of PTFePPc / reduction; The PTFePPc / reduction Graphene oxide composites were heat-treated at 700 °C for 2 hours to obtain N / S double-doped graphene-supported Fe with a mass ratio of 3:1. 9 S 10 Nanocrystalline [PTFePPc / rGO, 3:1, 700 °C].

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com