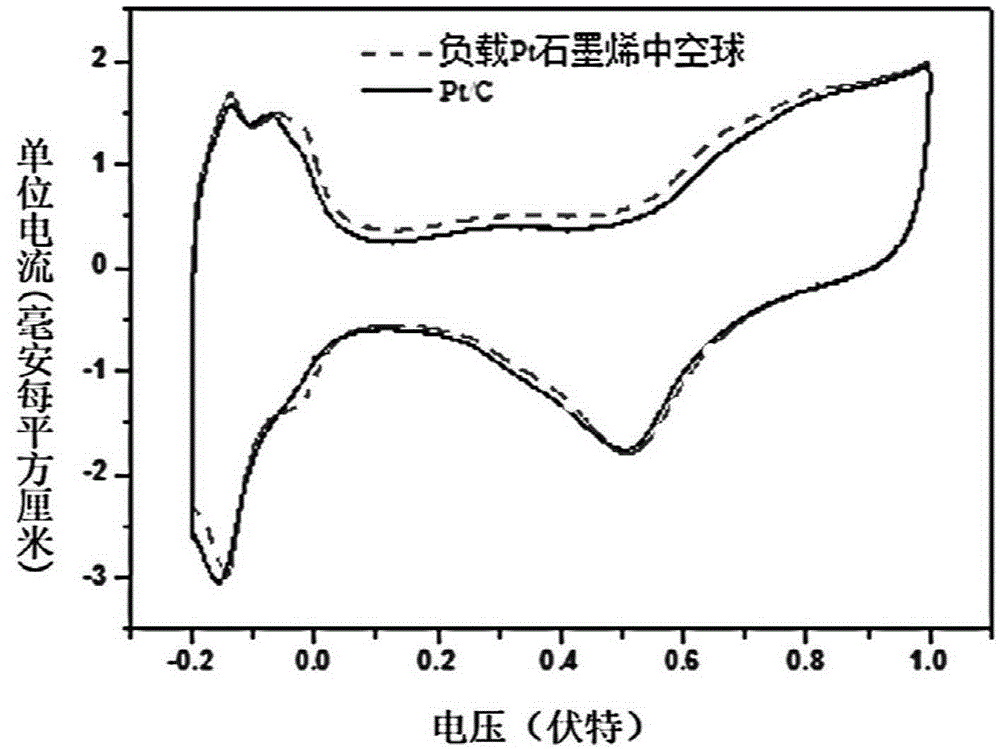

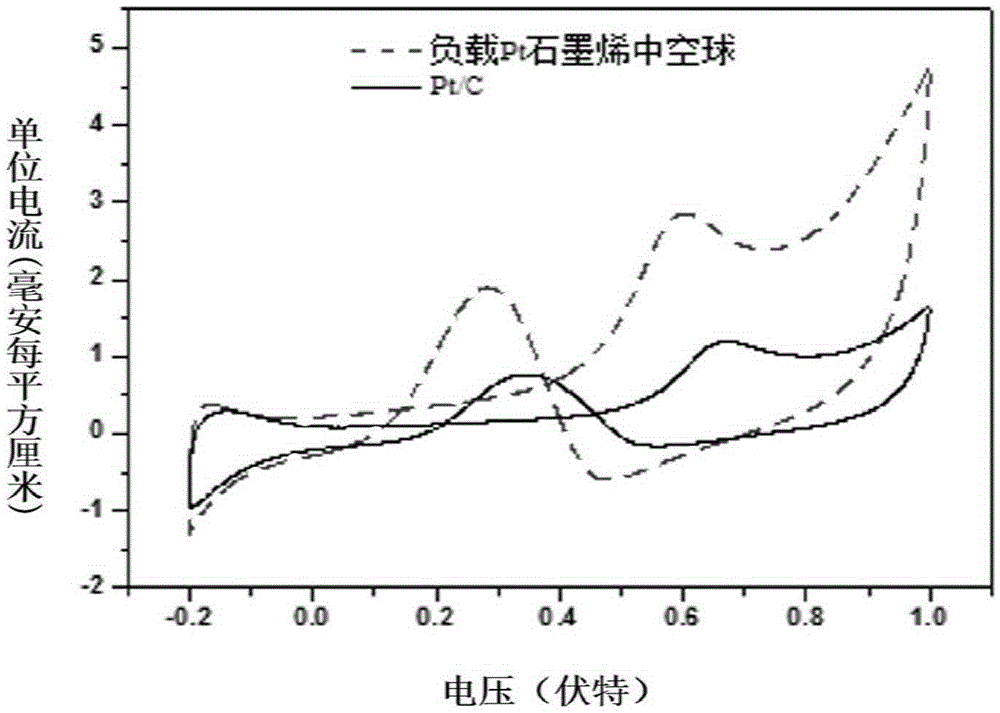

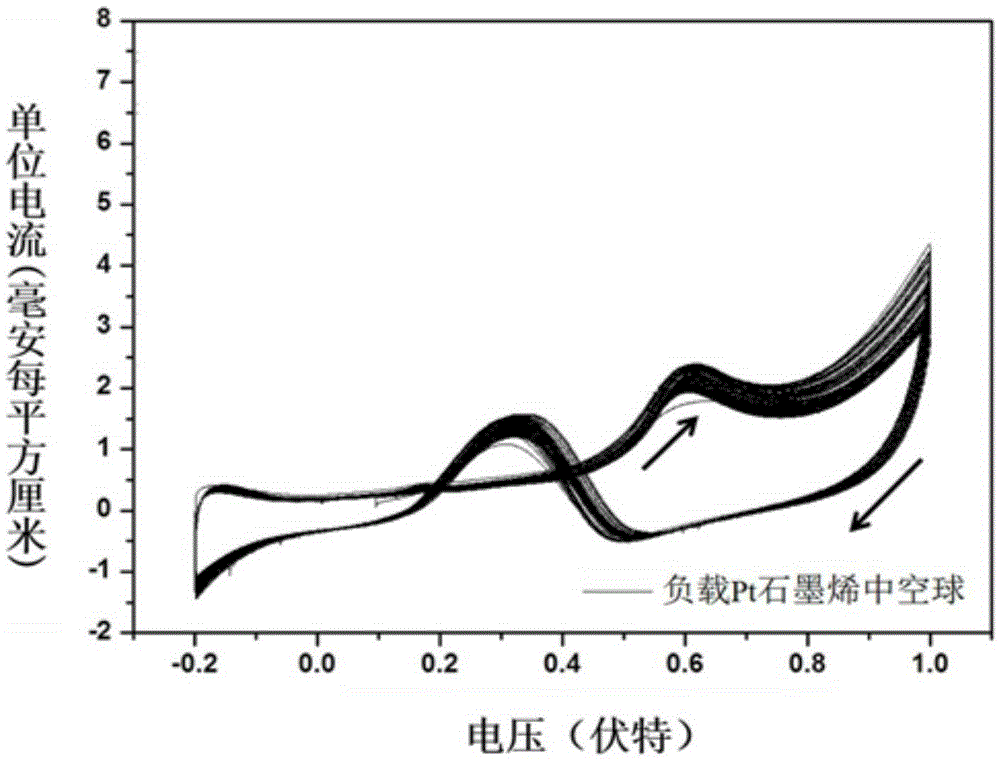

Pt-loaded graphene hollow microspherical catalyst and preparation method and application therefor

A graphene and catalyst technology, applied in the field of fuel cells, can solve problems such as cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A kind of preparation method of carrying Pt graphene hollow microsphere catalyst specifically comprises the following steps:

[0036] (1) First weigh 2g of graphite powder (Shanghai Colloidal Chemical Factory, chemically pure) and 2g of sodium nitrate (Guangzhou Chemical Reagent Factory, analytically pure) and put them into a dry 1000mL flask, then add them in an ice-water bath with stirring 110 mL of concentrated sulfuric acid (Beijing Chemical Plant, 98.3% analytically pure) with a mass fraction of 98% was stirred for 10 min, and 12 g of potassium permanganate (Guangzhou Chemical Reagent Factory, analytically pure) was added in 5 batches, and the ice bath was removed after 20 min of reaction. Stirring was continued at room temperature for 40 hours, at which time the reactant in the flask turned into a dark brown viscous solution; then 180 mL of distilled water was added to continue the reaction for 10 min (at room temperature), and then 560 mL of warm water (the temper...

Embodiment 2

[0045] A kind of preparation method of carrying Pt graphene hollow sphere catalyst specifically comprises the following steps:

[0046] (1) First weigh 3g of graphite powder (Shanghai Colloidal Chemical Factory, chemically pure) and 3g of sodium nitrate (Guangzhou Chemical Reagent Factory, analytically pure) and put them into a dry 1000mL flask, then add them in an ice-water bath with stirring 110 mL of concentrated sulfuric acid (Beijing Chemical Plant, 98.3% analytically pure) with a mass fraction of 98% was stirred for 15 min, and 18 g of potassium permanganate (Guangzhou Chemical Reagent Factory, analytically pure) was added in 6 batches, and the ice bath was removed after 30 min of reaction. Stirring was continued at room temperature for 45 hours. At this time, the reactant in the flask turned into a dark brown viscous solution; Mass fraction is 30% hydrogen peroxide (Guangzhou Chemical Reagent Factory, 30wt% analytically pure) reaction 1h (it should be pointed out that t...

Embodiment 3

[0054] A kind of preparation method of carrying Pt graphene hollow sphere catalyst specifically comprises the following steps:

[0055] (1) First weigh 5g of graphite powder (Shanghai Colloidal Chemical Factory, chemically pure) and 5g of sodium nitrate (Guangzhou Chemical Reagent Factory, analytically pure) and put them into a dry 1000mL flask, then add them in an ice-water bath with stirring 110 mL of concentrated sulfuric acid (Beijing Chemical Plant, 98.3% analytically pure) with a mass fraction of 98% was stirred for 20 min, and 30 g of potassium permanganate (Guangzhou Chemical Reagent Factory, analytically pure) was added in 6 batches, and the ice bath was removed after 40 min of reaction. Stirring was continued at room temperature for 50 hours. At this time, the reactant in the flask turned into a dark brown viscous solution; Mass fraction is 30% hydrogen peroxide (Guangzhou Chemical Reagent Factory, 30wt% analytically pure) reaction 50min (it should be pointed out tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com