Preparation method of modified soybean dietary fiber powder with sugar and lipid-lowering effects

A technology for soybean dietary fiber and function, applied in the field of food processing, can solve the problems of high viscosity of oligosaccharides, poor product quality, unsuitability, etc., and achieve the effects of increasing output, low work efficiency, and reducing labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

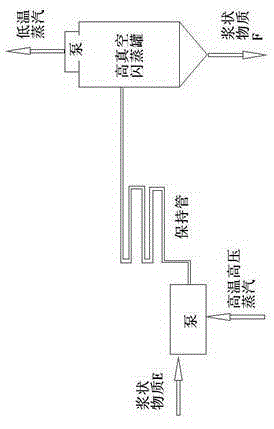

Method used

Image

Examples

Embodiment 1

[0093] Example 1. The preparation method of the modified soybean dietary fiber powder with hypoglycemic and lipid-lowering effects comprises the following steps:

[0094] Step 1: Hydrolysis. Mix wet okara and water according to wet okara: water = 1:1.5. The parts by weight are mixed and stirred for 15 to 20 minutes to fully hydrolyze the wet bean dregs to obtain a pulpy substance A. The moisture content of wet okara is 80%.

[0095] Step 2: Neutralize. Adjust the pH value of slurry A to 7.5 with lye to prepare slurry B.

[0096] Step 3: Add oligosaccharides. The oligosaccharide and the pulp-like substance B are mixed according to the weight ratio of oligosaccharide: pulp-like substance B=1:3 to prepare the pulp-like substance C. The oligosaccharides are galacto-oligosaccharides.

[0097] Step 4: Emulsify. The pulpy substance C was emulsified with an emulsifier, the emulsification pressure was 150 bar, and the emulsification time was 5 minutes to prepare the pulpy subst...

Embodiment 2

[0102] Example 2. The preparation method of the modified soybean dietary fiber powder with hypoglycemic and lipid-lowering effects is characterized in that it comprises the following steps:

[0103] Step 1: Hydrolysis. The wet okara and water are mixed according to the ratio of wet okara: water = 1:2 parts by weight, and stirred for 15-20 minutes to fully hydrolyze the wet okara to obtain slurry A. The moisture content of wet okara is 70%.

[0104] Step 2: Neutralize. Adjust the pH value of slurry A to 7.8 with lye to prepare slurry B. Lye is soda ash.

[0105] Step 3: Add oligosaccharides. The oligosaccharide and the pulp-like substance B are mixed according to the weight ratio of oligosaccharide: pulp-like substance B=4 to prepare the pulp-like substance C; the oligosaccharide is lactulose.

[0106] Step 4: Emulsify. The pulpy substance C was emulsified with an emulsifier at a pressure of 250 bar for 7 minutes to obtain a pulpy substance D.

[0107] Step 5: Homogeniz...

Embodiment 3

[0111] Example 3. The preparation method of the modified soybean dietary fiber powder with hypoglycemic and lipid-lowering effects is characterized in that it comprises the following steps:

[0112] Step 1: Hydrolysis. Mix wet bean dregs and water according to the ratio of wet bean dregs: water = 1:1.7 parts by weight, and stir for 15-20 minutes to fully hydrolyze the wet bean dregs to obtain slurry substance A; bean dregs are by-products after protein and fat are extracted, protein, The fat content is already very low. The moisture content of wet okara is 60%.

[0113] Step 2: Neutralize. Adjust the pH value of slurry A to 7.7 with lye to prepare slurry B. The lye is sodium hydroxide.

[0114] Step 3: Add oligosaccharides. The oligosaccharide and the pulp-like substance B are mixed according to the weight ratio of oligosaccharide: pulp-like substance B=1:3.5 to prepare the pulp-like substance C.

[0115] Step 4: Emulsify. The pulpy substance C was emulsified with an e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com