Alkyl phosphorus dihalide preparing method

A technology of hydrocarbyl phosphorus dihalide and phosphorus trihalide, which is applied in chemical instruments and methods, organic chemistry, compounds of Group 5/15 elements of the periodic table, etc. problem, to achieve the effect of high product purity, high reaction yield and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

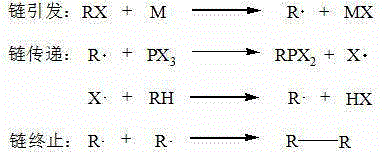

Method used

Image

Examples

Embodiment Construction

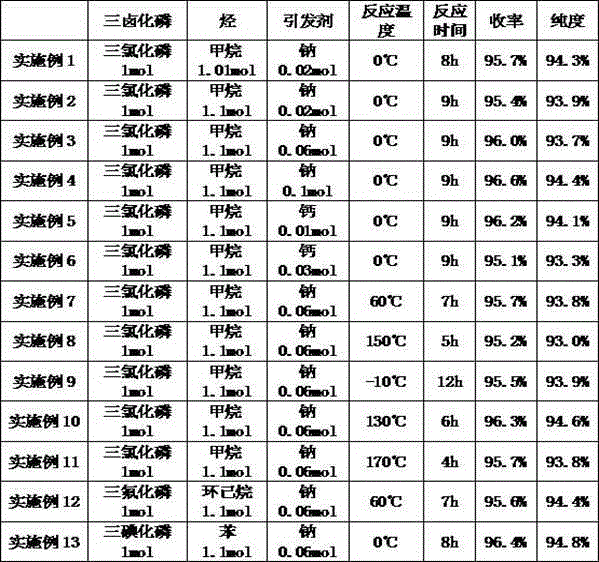

[0027] The present invention will be further described below in conjunction with embodiment.

[0028] The specific operation steps of the preparation method of the present invention are: adding phosphorus trihalide and hydrocarbons into the reaction flask and mixing them, introducing protective gas (nitrogen or other inert gases) to remove the air in the reaction kettle, and then heating to the reaction temperature and maintaining a constant temperature , into the reaction flask or add hydrocarbons dropwise, the addition of hydrocarbons reached 3% to 5% of the total amount of the addition of initiators, continue to slowly add hydrocarbons under stirring conditions, and maintain a constant temperature for reaction, when hydrocarbons After adding all the mixture, continue to keep warm for 2 hours, take a sample for gas chromatography analysis, and the reaction ends when the hydrocarbon content in the sample is lower than 1.0%. Adjust the temperature of the materials in the react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com