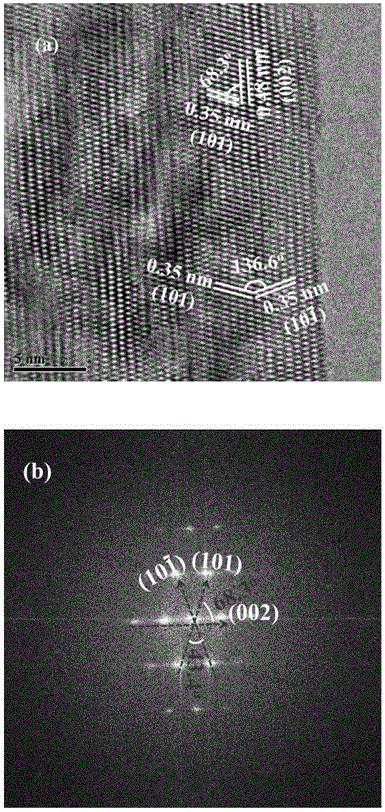

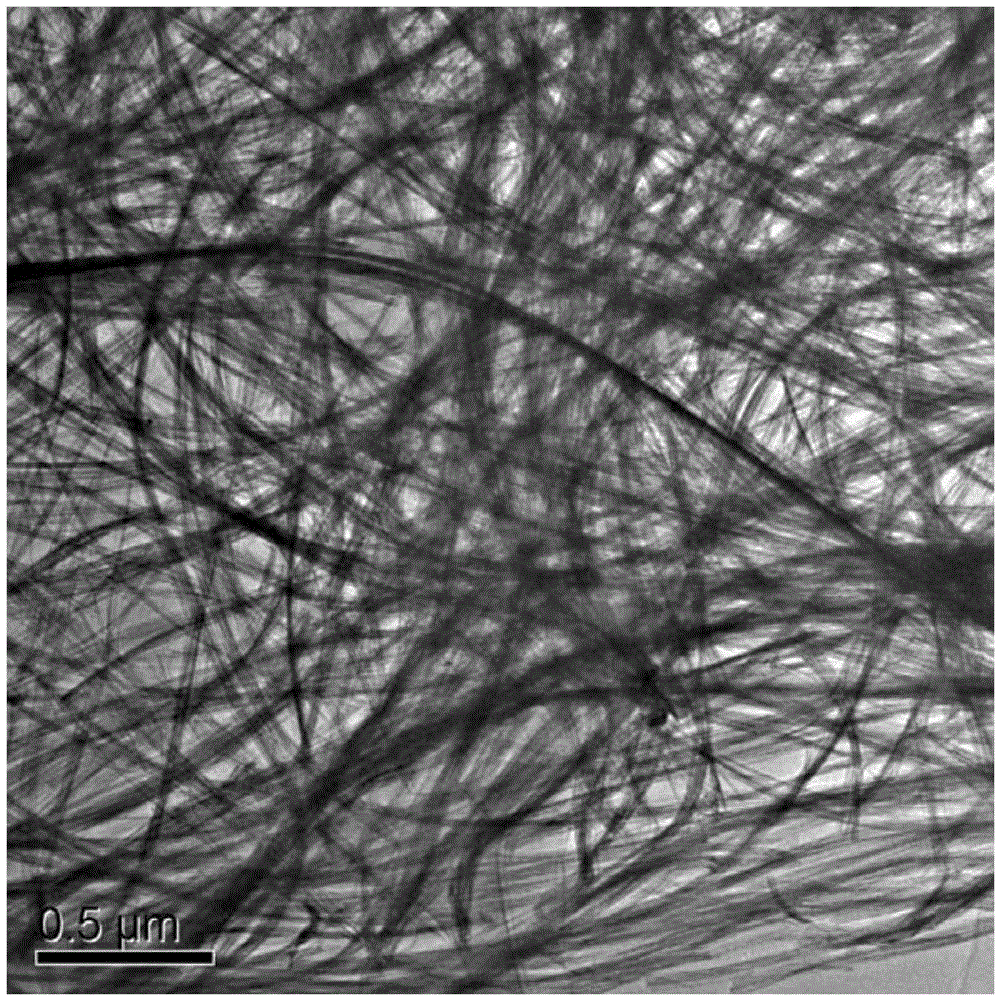

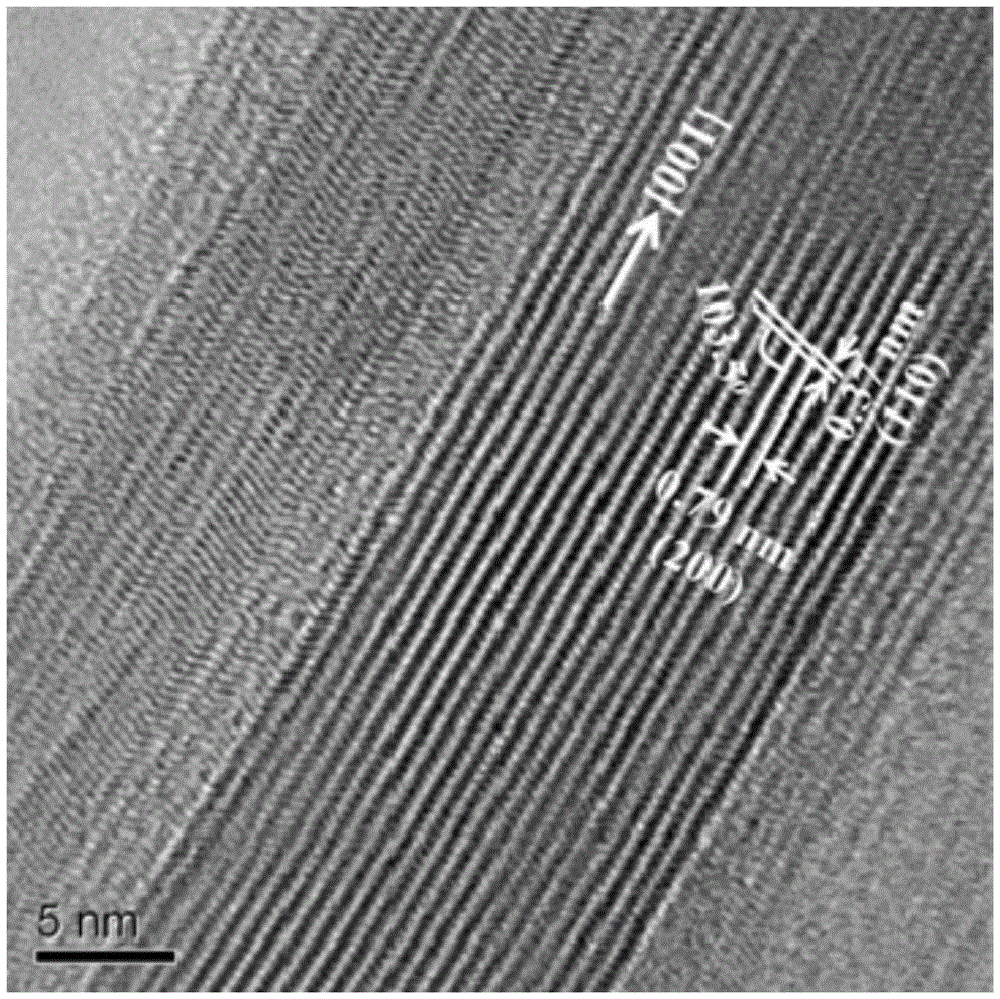

Anatase titanium dioxide nanoribbons exposing {010} crystal face and preparation method thereof

A technology of titanium dioxide and nanobelts, which is applied in the field of photocatalysis, can solve the problems of low proportion, large pollution in the preparation process, and small specific surface area, and achieve the effects of narrow width, improved photocatalytic activity, and small thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 10mmolTiO 2 The powder was mixed evenly with 50ml of 12M NaOH solution, then transferred to a tetrafluoroethylene-lined hydrothermal reaction kettle, placed in an oven at 130°C for 48 hours, cooled to room temperature naturally, and the product in the kettle was poured out, and then the white product was mixed with 5 mmol phenol in 10 M H 2 NO 3 The aqueous solution was subjected to alcohol-assisted self-assembly reaction, then washed with deionized water to PH = 5.5, and dried at 100°C to obtain ultra-thin titanate nanobelts, which were then calcined at 700°C for 1 hour in an air atmosphere to obtain close to 100% exposed {010 } faceted anatase titania nanobelts.

Embodiment 2

[0032] 10mmolTiO 2 The powder was mixed evenly with 50ml of 20M NaOH solution, then transferred to a tetrafluoroethylene-lined hydrothermal reaction kettle, placed in a 120°C oven for hydrothermal reaction for 72 hours, cooled naturally to room temperature, poured out the product in the kettle, and then mixed the white product with The 10M HCl aqueous solution containing 10mmol benzyl alcohol was used for alcohol-assisted self-assembly reaction, then washed with deionized water until pH = 7, and dried at 120°C to obtain ultra-thin titanate nanoribbons, and then calcined at 400°C for 5h in an oxygen atmosphere. That is, the anatase titania nanoribbons with nearly 100% exposed {010} crystal planes were obtained.

Embodiment 3

[0034] 10mmolTiO 2 The powder was mixed evenly with 50ml of 10M NaOH solution, then transferred to a tetrafluoroethylene-lined hydrothermal reaction kettle, placed in a 150°C oven for hydrothermal reaction for 48 hours, cooled to room temperature naturally, and the product in the kettle was poured out, and then the white product was mixed with 0.1M HCl aqueous solution containing 1mmol benzyl alcohol was used for alcohol-assisted self-assembly reaction, then washed with deionized water to pH = 7, dried at 60°C to obtain ultra-thin titanate nanoribbons, and then calcined at 600°C in an oxygen atmosphere After 2h, the anatase titanium dioxide nanobelts with nearly 100% exposed {010} crystal faces were obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com