Preparation method of cold ramming paste specially used for submerged arc furnace whole furnace construction

A technology of submerged arc furnace and cold paste, which is applied in the field of cold paste preparation for the overall construction of submerged arc furnaces, so as to avoid the release of toxic fumes and ensure the construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

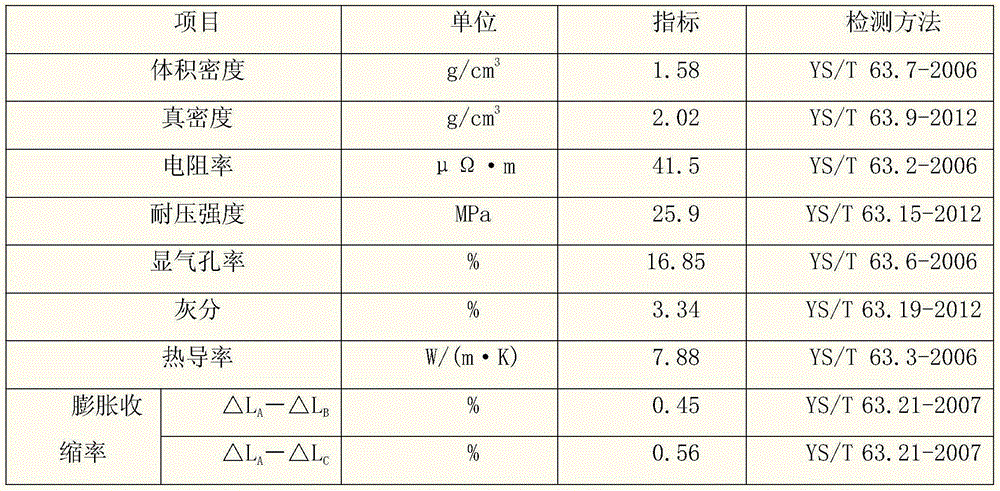

Embodiment 1

[0034] The weight proportions of aggregates, binders and additives used for cold stamping for integral furnace building are as follows: 76 parts: 18 parts: 6 parts;

[0035] The weight ratio of the aggregate is: 35 parts of electric calcined anthracite, 20 parts of pitch coke, 45 parts of artificial graphite, and the particle size is 5mm;

[0036] The weight ratio of the binder is: 40 parts of modified coal tar pitch, 50 parts of coal tar, and 10 parts of anthracene oil;

[0037] The weight ratio of the additives is: 60 parts of 2,4-dinitrotoluene, 1 part of sulfur and 39 parts of titanium diboride.

[0038] According to the above formula, put the prepared aggregate into the kneading pot preheated to 60 ℃ and mix for 25 minutes, then add the binder and additives and knead for 40 minutes, and finally take it out of the pot and cool it, that is, it has higher density and strength, and is more Low porosity and expansion and shrinkage special cold paste product for integral furna...

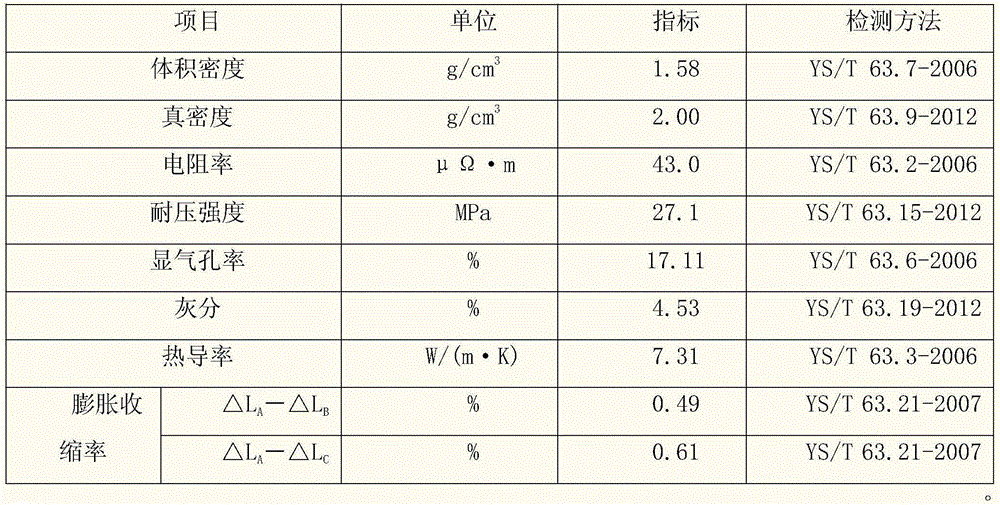

Embodiment 2

[0043] The weight ratio of the aggregate, binder and additives used for cold ramming paste for integral furnace building is: 75 parts: 18 parts: 7 parts;

[0044] The weight ratio of the aggregate is: 35 parts of electric calcined anthracite, 20 parts of anode butt, 35 parts of artificial graphite, 10 parts of pitch coke, and the particle size is 10mm;

[0045] The weight ratio of the binder is: 40 parts of modified coal tar pitch, 50 parts of coal tar, and 10 parts of anthracene oil;

[0046] The weight ratio of the additives is: 54 parts of 2,4-dinitrotoluene, 1 part of sulfur, and 45 parts of aluminum phosphate.

[0047] According to the above formula, put the prepared aggregate into the kneading pot preheated to 80°C and mix for 15 minutes, then add the binder and additives and knead for 30 minutes, and finally take it out of the pot and cool it, that is, it has higher density and strength, and is more Low porosity and expansion and shrinkage special cold paste product fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com