Low-cost and high-yield adenine preparation method

A technology of adenine and epichlorohydrin, which is applied in the field of pharmaceutical biochemical industry, can solve the problems of large amount of three wastes, difficulty in industrial production, and high raw material prices, and achieve the effects of reducing production costs, increasing yields, and low product costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

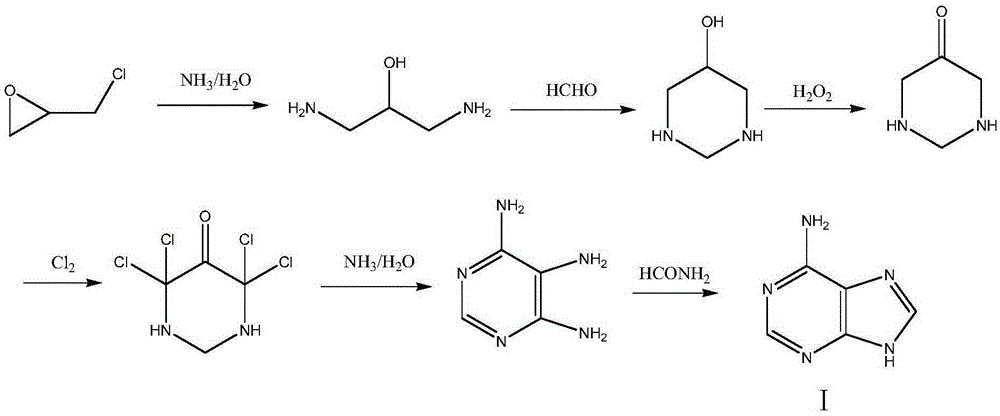

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: the preparation of adenine

[0037] Add 50 grams of methanol, 9.3 grams (0.1 moles) of epichlorohydrin, 22.5 grams (0.33 moles) of 25% ammonia water in a 250 milliliter reactor with a tail gas absorption device, and react for 3 hours at 25 to 30 ° C; add 11.0 grams (0.11 moles) 30% formaldehyde, reacted at 25 to 30°C for 2 hours; added 15.0 grams (0.13 moles) of 30% hydrogen peroxide, and reacted at 25 to 30°C for 2 hours; slowly introduced 33.0 grams (0.46 moles ) chlorine gas, pass through, react at 25 to 30°C for 1 hour, add 35 grams (0.62 moles) of 30% ammonia water, and react at 25 to 30°C for 3 hours; add 6.8 grams (0.15 moles) of formamide, heat, and react at 85 to 90°C 2 hours, while recovering the distilled methanol; after recovering methanol, add 0.5 g of activated carbon, react at 80-85 ° C for 2- hours, filter while it is hot, cool the filtrate to 0-5 ° C, filter, and dry to obtain 10.5 g of light yellow solid gland Purine, yield 87.5%, HPLC p...

Embodiment 2

[0038] Embodiment 2: the preparation of adenine

[0039] The 50 g of methanol in Example 1 was replaced with 50 g of ethanol, and the rest were the same as in Example 1 to obtain 10.6 g of light yellow solid adenine with a yield of 88.3% and a HPLC purity of 99.1%.

Embodiment 3

[0040] Embodiment 3: the preparation of adenine

[0041] 50 grams of isopropanol was used instead of 50 grams of methanol in Example 1, and the rest were the same as in Example 1 to obtain 10.3 grams of light yellow solid adenine with a yield of 85.8% and a HPLC purity of 99.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com