Voltage-sensitive ceramic powder and obtained piezoresistor

A technology of varistors and varistor ceramics, which is applied in the direction of capacitors, fixed capacitors, fixed capacitor dielectrics, etc., can solve the problem of high cost, and achieve the effects of uniform powder, good molding process, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

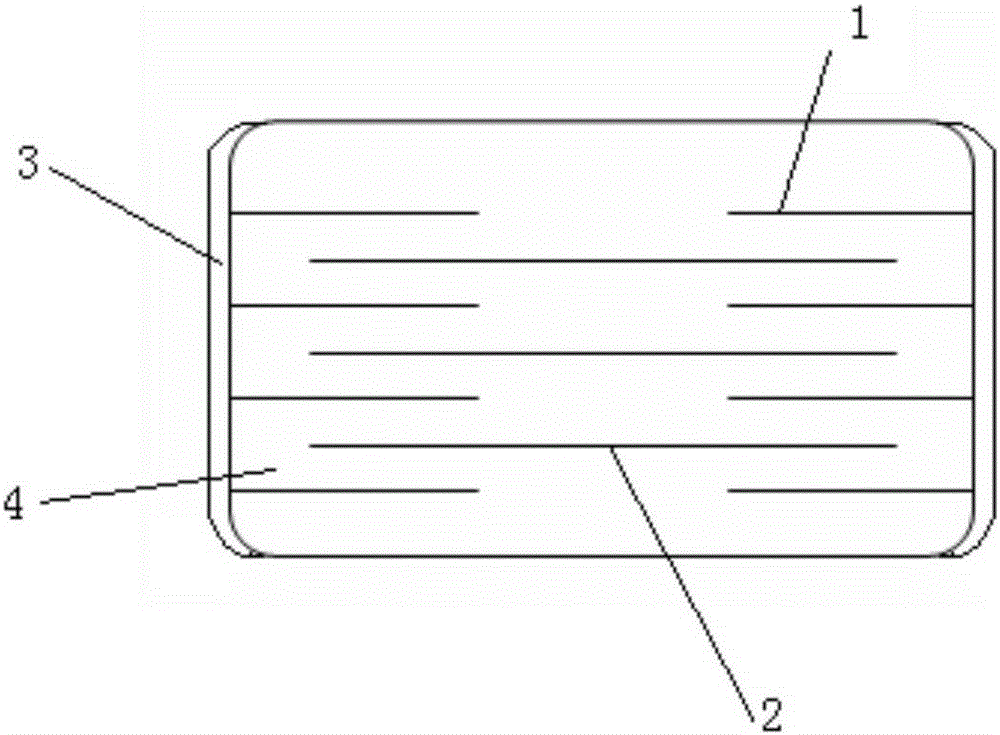

[0011] A kind of pressure-sensitive ceramic powder, doping rare earth oxide into ZnO-Bi 2 o 3 The pressure-sensitive ceramic system is mixed, and the rare earth oxide is Y 2 o 3 Prepare according to the blending conditions in Table 1, then add absolute ethanol, toluene, dispersant, plasticizer, defoamer, adhesive and other ball milling dispersion, slurry and prepare raw film sheet by steel tape casting; According to the multi-layer chip ceramic component process, the internal electrode is printed, the thickness of the internal electrode is (1.0-2.0) μm, the green body is cut into a cuboid with a size of 1812, and the adhesive is deglued at 350°C in the air for 30 hours; then in an oxygen-enriched atmosphere Sintering at 950-1000°C for 2 hours; then chamfering, sealing, firing, and electroplating terminal electrodes to make a multilayer chip ceramic varistor. The conventional performance (varistor voltage V1mA, nonlinear coefficient a, leakage current IL, peak current Ip, en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com