Charged type chlorine containing polymer nanofiltration membrane and preparation method thereof

A polymer and nanofiltration membrane technology, applied in the field of membrane separation, can solve problems such as few research results, and achieve the effects of reducing operating costs, improving separation efficiency, and high performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

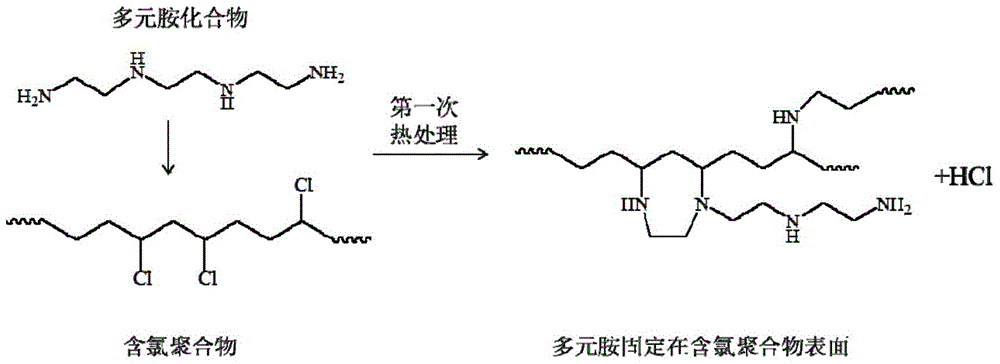

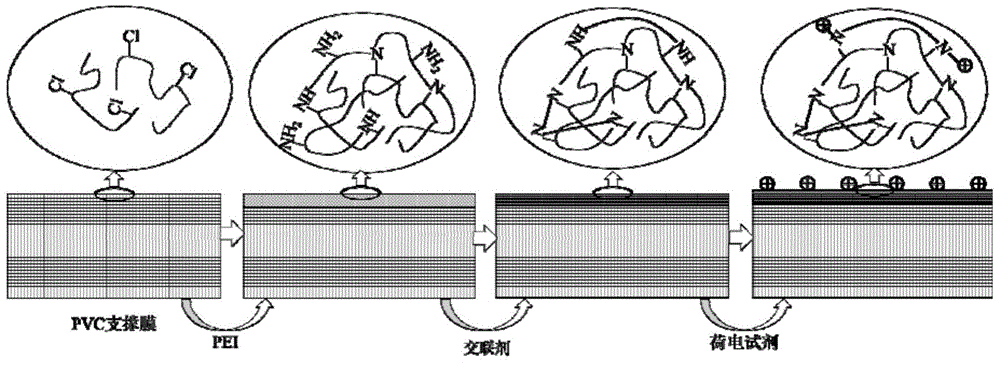

[0048] The preparation method of the charged chlorine-containing polymer nanofiltration membrane comprises the following steps:

[0049] 1) Uniformly coating the polyamine compound aqueous solution on the surface of the chlorine-containing polymer ultrafiltration membrane, and then performing the first heat treatment on the ultrafiltration membrane;

[0050] 2) Washing the ultrafiltration membrane treated in step 1) and immersing it in a mixed solution of a crosslinking agent and a charging reagent, and performing a second heat treatment to obtain a charged chlorine-containing polymer nanofiltration membrane.

[0051] Preferably, the polyamine compound in step 1) is selected from any one or more of tetraethylenepentamine, triethylenetetramine, polyethylene polyamine, and polyethyleneimine, and the polyamine compound solution is 10% by mass ~50% aqueous solution.

[0052] As a preference, the material of the chlorine-containing polymer ultrafiltration membrane described in ste...

Embodiment 1

[0060] A 15% polyethyleneimine (PEI) aqueous solution was coated on a flat polyvinyl chloride (PVC) ultrafiltration membrane, and rinsed with deionized water after the first heat treatment at 60°C for 10 hours. Then the film was immersed in 10% glutaraldehyde and 10% methacryloyloxyethyltrimethylammonium chloride (EPTAC) aqueous solution at 60°C for the second time. After heat treatment for 1 hour, a positively charged low-pressure high-flux PVC / PEI polymer nanofiltration membrane is obtained.

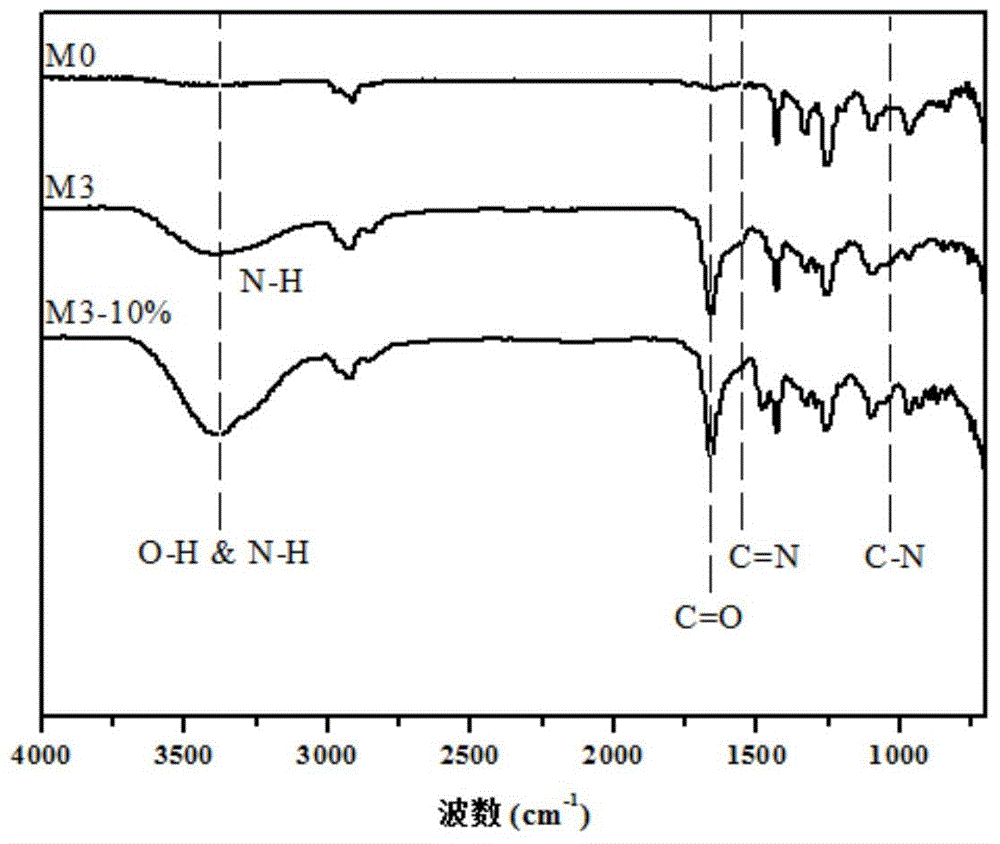

[0061] attached image 3 Infrared reflection spectra of the surface before and after film treatment. Compared with the PVC support layer M0, M3 after depositing the PEI layer and crosslinking with glutaraldehyde, at 3377cm -1 and 1035cm -1 Two new absorption peaks appear, corresponding to -NH of PEI 2 and -C-N- single-bond stretching vibrations, indicating the stable existence of the PEI layer; at 1546cm -1 The new absorption peak at is the C=N stretching vibration peak of the Sch...

Embodiment 2

[0073] A 40% triethylenetetramine aqueous solution was coated on a chlorinated polyethylene flat ultrafiltration membrane, and after the first heat treatment at 80°C for 2 hours, it was rinsed with deionized water. Then soak the film in 0.1% by mass percentage of dicyclopentadiene epoxide and 8% by mass of 1,3-propane sultone ethanol solution, at 50°C for the second time After heat treatment for 10 hours, a negatively charged low-pressure high-flux chlorinated polyethylene / triethylenetetramine polymer nanofiltration membrane is obtained.

[0074] Under the test conditions of 25°C and 0.3MPa, the pure water flux of the prepared charged chlorine-containing polymer nanofiltration membrane is 61.9L / (m 2 h), the rejection rate of 0.01mol / L sodium sulfate is 90.1%, the rejection rate of 0.01mol / L sodium chloride is 42.1%, and the rejection rate of Congo red is 99.9%. The membrane is placed at 60°C for deionization The flux and interception performance remained unchanged when the wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com