Ester hydrogenation catalyst and preparation method thereof, and ester hydrogenation reaction method

A technology for hydrogenation of esters and catalysts, applied in chemical instruments and methods, preparation of hydroxyl compounds, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as inapplicability, and achieve high hydrogenation activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

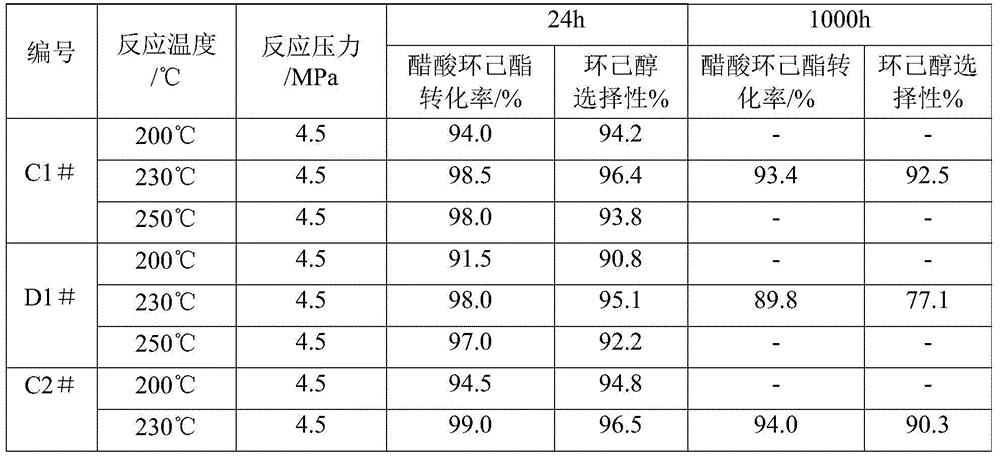

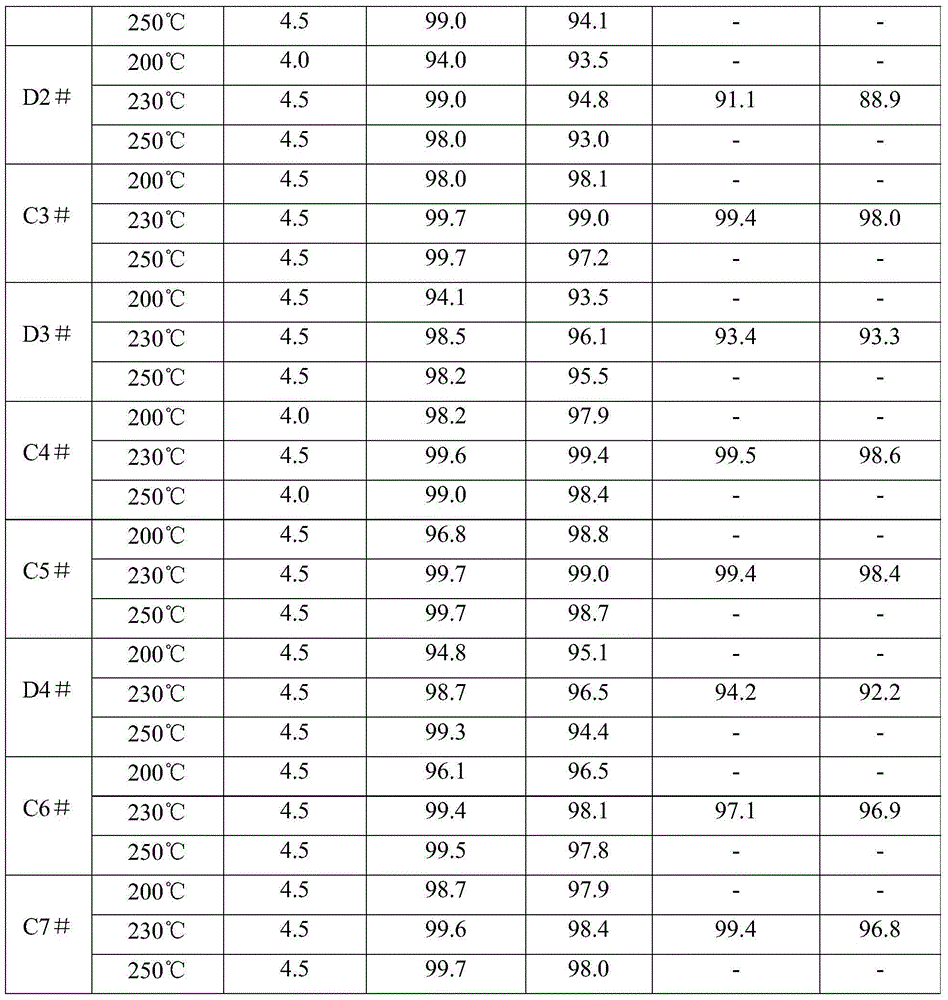

Examples

preparation example Construction

[0016] The preparation method of ester hydrogenation catalyst provided by the invention comprises the following steps:

[0017] (1) adjusting the pH value of the water-soluble aluminum salt solution to 4-10 with a first alkaline substance to obtain slurry A;

[0018] (2) prepare mixed solution B and mixed solution C that all contain water-soluble copper salt solution and water-soluble zinc salt solution, the copper / zinc mol ratio in described mixed solution B<the copper / zinc mol in described mixed solution C Compare;

[0019] (3) Mix the mixed solution B with the slurry A to obtain a mixture E, and adjust the pH value of the mixture E to 4-10 with a second alkaline substance, then add the mixed solution C and the water-soluble A solution D of at least one of a platinum compound, a water-soluble palladium compound and a water-soluble tin compound to obtain a mixture F, and then adjust the pH value of the mixture F to 4-10 with a third alkaline substance, followed by solid-liqu...

preparation example 1

[0044] In this preparation example, a three-stage precipitation method is used to prepare copper-zinc-aluminum composite oxides.

[0045] 150.01 g (0.40 mol) of aluminum nitrate nonahydrate was dissolved in 300 mL of deionized water to obtain an aqueous solution of aluminum nitrate. The pH value of the aluminum nitrate aqueous solution was titrated to 7.0 with a 1 mol / L aqueous sodium hydroxide solution under stirring to obtain a white turbid slurry A. 72.48 g of copper nitrate trihydrate was dissolved in 128 g of deionized water, and the resulting solution was divided into two portions of 20.48 g and 180 g. 89.25 g of zinc nitrate hexahydrate was dissolved in 150 g of deionized water, and the obtained solution was divided into two portions of 23.25 g and 216 g. 20.48 g of copper nitrate aqueous solution (the content of copper nitrate is 0.03 mol) and 216 g of zinc nitrate aqueous solution (the content of zinc nitrate is 0.27 mol) were mixed to obtain mixed solution B. A mix...

preparation example 2

[0050] In this preparation example, a three-stage precipitation method is used to prepare copper-zinc-aluminum composite oxides.

[0051]150.01 g (0.40 mol) of aluminum nitrate nonahydrate was dissolved in 300 mL of deionized water to obtain an aqueous solution of aluminum nitrate. The pH value of the aluminum nitrate aqueous solution was titrated to 6.0 with a 1 mol / L aqueous sodium hydroxide solution under stirring to obtain a white turbid slurry A. 99.87g of copper sulfate pentahydrate was dissolved in 150g of deionized water, and the obtained solution was divided into two parts of 24.87g and 225g. 59.50 g of zinc nitrate hexahydrate was dissolved in 90 g of deionized water, and the obtained solution was divided into two parts of 119.50 g and 30 g. 24.87g of copper sulfate aqueous solution (the content of copper sulfate is 0.04mol) and 119.50g of zinc nitrate aqueous solution (the content of zinc nitrate is 0.15mol) were mixed to obtain mixed solution B. Mix 225 g of copp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com