Synthesis method of triaminoguanidinium nitrate

A technology of guanidine nitrate and synthesis method, applied in the field of synthesis of triaminoguanidine nitrate, can solve problems such as unsatisfactory manufacturing technology, dangerous operation technology, high price, etc., and achieves safe synthesis route, high purity, and synthesis time. short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

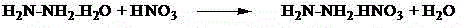

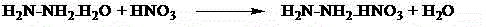

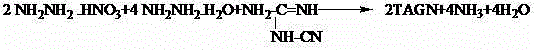

Method used

Image

Examples

Embodiment 1

[0030] Synthesis of triaminoguanidine nitrate in 500ml container:

[0031] Adding the concentration of 37ml in the 500ml four-necked flask equipped with a magnetic stirrer, condensing device and tail gas receiving device is 80% hydrazine hydrate and 72ml deionized water, and dripping 42ml concentration under stirring is 65% nitric acid, control The temperature of the system is below 40°C, after the dropwise addition is completed, test the pH value and adjust the pH value to 7;

[0032] Add 73.3g of technical grade guanidine nitrate and 210ml of hydrazine hydrate with a concentration of 80% to the system, and heat up under stirring. When the internal temperature rises to 61°C, the guanidine nitrate is completely dissolved, and then continue to heat up. When the system temperature reaches Reflux starts at 90°C, accompanied by a large amount of gas discharge. When the temperature reaches 95°C, start timing, control the reaction temperature at 95°C~98°C, and control the reaction t...

Embodiment 2

[0037] Synthesis of triaminoguanidine nitrate in 1000ml container:

[0038] Adding the concentration of 75ml in the 1000ml four-necked flask equipped with a magnetic stirrer, condensing device and tail gas receiving device is 80% hydrazine hydrate and 150ml deionized water, and dripping 85ml of concentration under stirring is 65% nitric acid, control The temperature of the system is below 40°C, after the dropwise addition is completed, test the pH value and adjust the pH value to 7;

[0039] Add 146.8g of technical grade guanidine nitrate and 420ml of hydrazine hydrate with a concentration of 80% to the system, heat and heat up under stirring, when the internal temperature rises to 65°C, the guanidine nitrate dissolves completely, then continue to heat up, when the system temperature reaches Reflux starts at 90°C, accompanied by a large amount of gas discharge. When the temperature reaches 95°C, start timing, control the reaction temperature at 95°C~100°C, and control the reac...

Embodiment 3

[0044] Synthesis of triaminoguanidine nitrate in 2000ml container:

[0045] Adding the concentration of 150ml in the 2000ml four-neck flask equipped with a magnetic stirrer, condensing device and tail gas receiving device is 80% hydrazine hydrate and 290ml deionized water, and adding dropwise 210ml concentration is 65% nitric acid under stirring state, control The temperature of the system is below 40°C, after the dropwise addition is completed, test the pH value and adjust the pH value to 7;

[0046] Add 294.0g of technical grade guanidine nitrate and 850ml of hydrazine hydrate with a concentration of 80% to the system, and heat up under stirring. When the internal temperature rises to 62°C, the guanidine nitrate is completely dissolved, and then continue to heat up. When the system temperature reaches The reflux starts at 90°C, and a large amount of gas is discharged. When the temperature reaches 96°C, the timing starts, and the reaction temperature is controlled at 96°C~99°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com