Device and process for separating coal tar components

A coal tar and process technology, applied in the field of coal chemical industry, can solve the problems of low separation and utilization efficiency, complexity, and large amount of phenol-containing wastewater, and achieve the effects of easy expansion of production, high energy consumption, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below through embodiments in conjunction with the accompanying drawings.

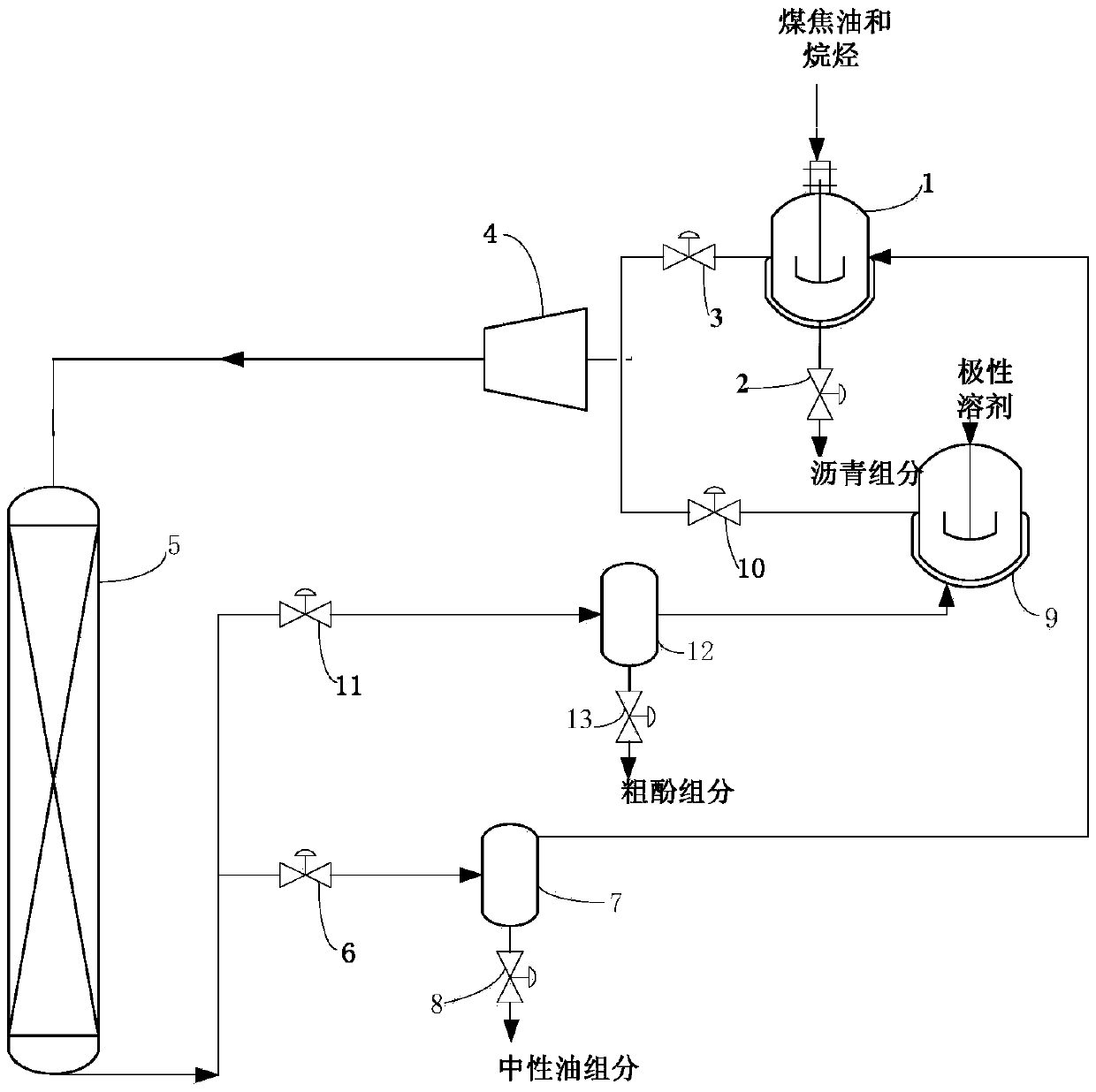

[0038] see figure 1, a coal tar component separation device, including an extractor 1, a booster pump 4, a chromatographic column 5, a first distillation tower 7, a second distillation tower 12 and a solvent storage tank 9. The middle part of the side wall of the extractor 1 is connected to the pressure pump 4 through the first electromagnetic valve 3, and the pressure pump 4 is also connected to the solvent storage tank 9, and a fifth electromagnetic valve 10 is arranged between the pressure pump 4 and the solvent storage tank 9; The booster pump 4 is connected to the upper end of the chromatographic column 5, the lower end of the chromatographic column 5 is connected to the bottom of the first distillation tower 7 and the second distillation tower 12 respectively, the top of the first distillation tower 7 is connected to the top of the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com