Fireflooding chemical ignition combustion improver and ignition method

An ignition-supporting and fire-flooding technology, which is applied in the direction of fuel additives, fuels, and liquid carbon-containing fuels, can solve the problems of high ignition costs, uneven heating, and large inapplicability to deep oil reservoirs, and achieves low operational risk and high ignition efficiency. Good reliability and the effect of improving oil production efficiency of fire flooding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

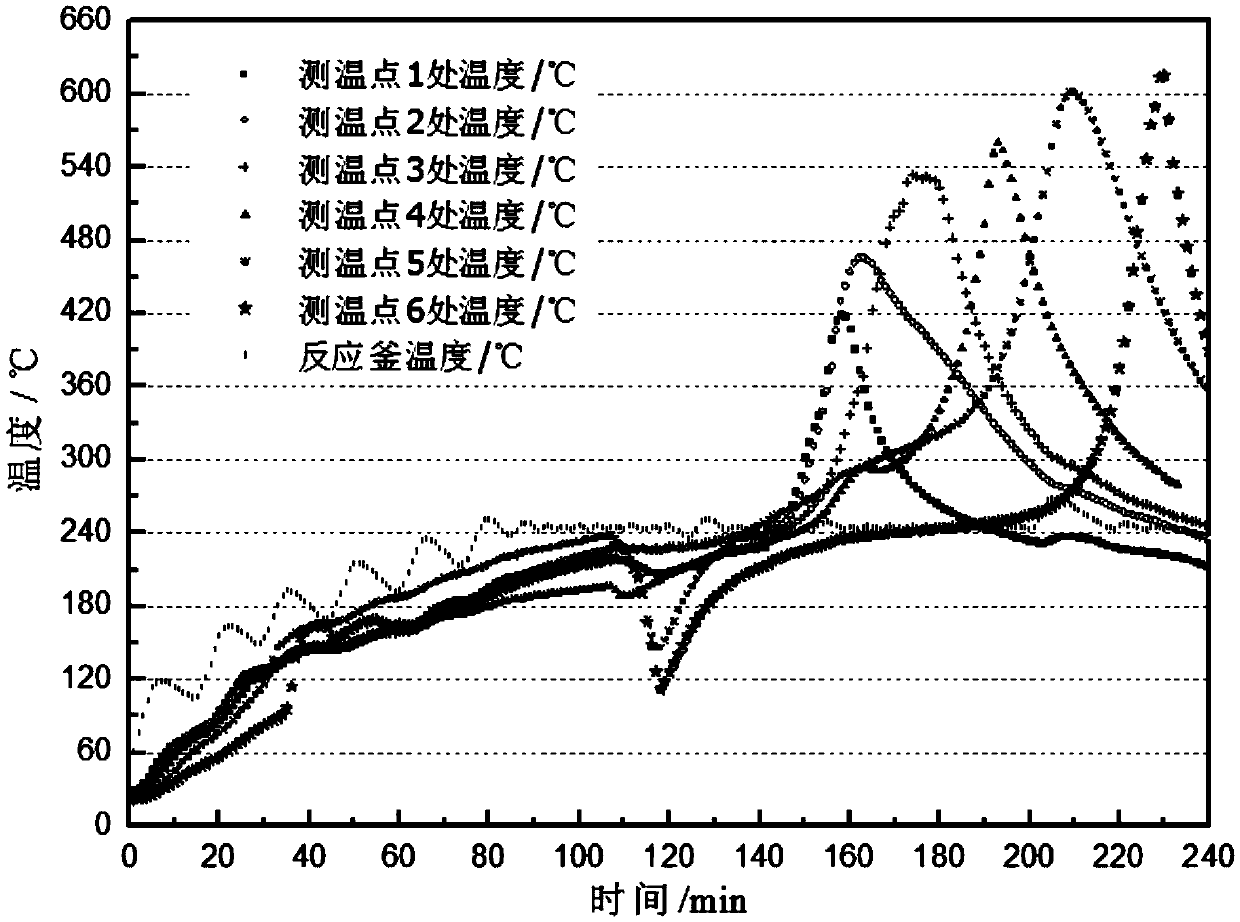

Image

Examples

Embodiment 1

[0043] This embodiment provides a fire flooding chemical ignition combustion accelerant, including A component and B component;

[0044] A component includes: carbon powder and iron acetylacetonate; B component includes: carbon powder, sulfur, magnesium aluminum powder (mixed in conventional proportions);

[0045] In terms of mass percentage, the dosage ratio of each component is respectively: 60% of iron acetylacetonate, 15% of carbon powder, 15% of magnesium aluminum powder and 10% of sulfur.

[0046] Above-mentioned fire flooding chemical ignition combustion accelerant is prepared like this:

[0047] Grind the raw materials of component A and component B to a fineness of more than 200 mesh (pass through a 200 mesh sieve), mix them separately (mechanical mixing according to conventional methods), and obtain component A powder and component B powder;

[0048] Use the extrusion method to granulate the powder of component A and powder of component B respectively, with a partic...

Embodiment 2

[0058] This embodiment provides a fire flooding chemical ignition combustion accelerant, including A component and B component;

[0059] A component includes: chromium and chromium oxide, cobalt naphthenate; B component includes: carbon powder, sulfur, magnesium aluminum powder (combined in conventional proportions);

[0060] In terms of mass percentage, the dosage ratio of each component is respectively: 10% of cobalt naphthenate, 60% of chromium and chromium oxide, 10% of carbon powder, 16% of magnesium aluminum powder, and 4% of sulfur.

[0061] Above-mentioned fire flooding chemical ignition combustion accelerant is prepared like this:

[0062] Grind the raw materials of component A and component B to a fineness of more than 200 mesh (pass through a 200 mesh sieve), mix them separately (mechanical mixing according to conventional methods), and obtain component A powder and component B powder;

[0063] Use the extrusion method to granulate the powder of component A and pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com