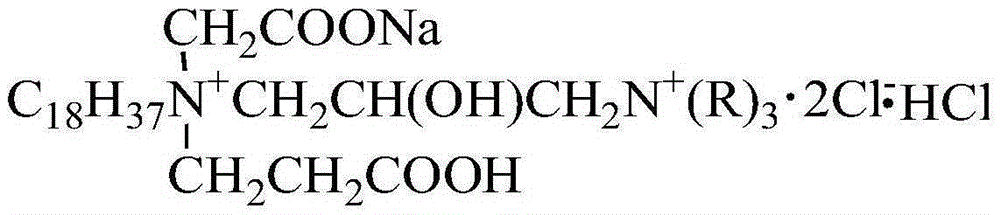

Dication and dianion type asphalt emulsifier and preparation method thereof

A technology of asphalt emulsifier and double anion, which is applied in the field of double cationic double anionic asphalt emulsifier and its preparation, can solve the problems of high requirements for production experimental equipment, high cost of emulsifier raw materials, poor stability of emulsified asphalt, etc., and achieve production cost Low, improve emulsification performance, improve the effect of performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

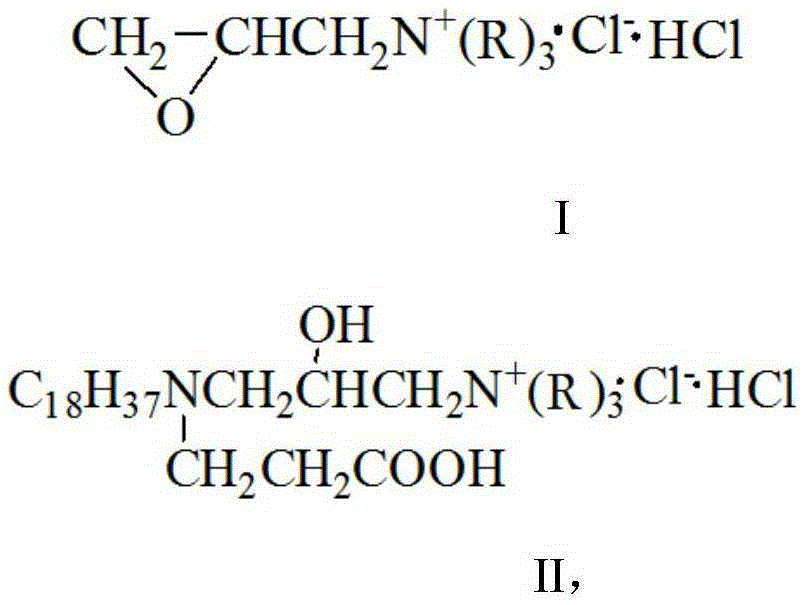

Method used

Image

Examples

Embodiment 1

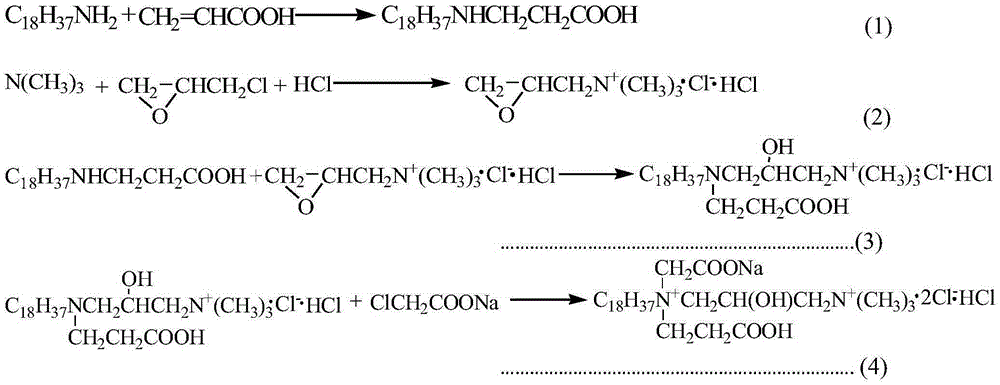

[0048] (1) Preparation of double cation double anionic asphalt emulsifier:

[0049] 1) Add 269.5g octadecylamine, 260g isopropanol in the reactor, heat and stir to dissolve. Then 73.5g of acrylic acid was added dropwise, and the reaction was stirred at 70°C for 2h.

[0050] 2) Add 193.1g of 33% trimethylamine aqueous solution into the reactor, gradually add 131.2g of 30% industrial hydrochloric acid, then gradually add 97.1g of epichlorohydrin, stir and react at 30-70°C for 2h, and obtain reaction intermediate A. The prepared reaction intermediate A was added dropwise to the synthesis product in step 1) above, and stirred at 70° C. for 2 h.

[0051] 3) 41.2g sodium hydroxide was dissolved in 80.0g water to obtain sodium hydroxide aqueous solution, 97.3g chloroacetic acid was dissolved in 180.0g water to obtain chloroacetic acid aqueous solution; sodium hydroxide aqueous solution was added dropwise in chloroacetic acid aqueous solution to obtain sodium chloroacetic acid aqueou...

Embodiment 2

[0060] (1) Preparation of double cation double anionic asphalt emulsifier:

[0061] 1) Add 269.5g octadecylamine, 260g isopropanol in the reactor, heat and stir to dissolve. Then 73.5g of acrylic acid was added dropwise, and the reaction was stirred at 65°C for 3h.

[0062] 2) Add 109.1g of triethylamine into the reactor, gradually add 131.2g of 30% industrial hydrochloric acid, then gradually add 97.1g of epichlorohydrin, stir and react at 30-70°C for 2h, and obtain reaction intermediate B. The prepared reaction intermediate B was added dropwise to the synthesis product in step 1) above, and stirred at 65° C. for 3 h.

[0063] 3) 41.2g sodium hydroxide was dissolved in 80.0g water to obtain sodium hydroxide aqueous solution, 97.3g chloroacetic acid was dissolved in 180.0g water to obtain chloroacetic acid aqueous solution; sodium hydroxide aqueous solution was added dropwise in chloroacetic acid aqueous solution to obtain sodium chloroacetic acid aqueous solution . The pre...

Embodiment 3

[0077] (1) Preparation of double cation double anionic asphalt emulsifier:

[0078] 1) Add 269.5g octadecylamine, 260g isopropanol in the reactor, heat and stir to dissolve. Then 73.5g of acrylic acid was added dropwise, and the reaction was stirred at 70°C for 2h.

[0079] 2) Add 189.6g of 85% triethanolamine to the reactor, gradually add 131.2g of 30% industrial hydrochloric acid, then gradually add 97.1g of epichlorohydrin, stir and react at 30-70°C for 2h, and obtain reaction intermediate C. The prepared reaction intermediate C was added dropwise to the synthesis product in step 1) above, and stirred at 70° C. for 2 h.

[0080] 3) 41.2g sodium hydroxide was dissolved in 80.0g water to obtain sodium hydroxide aqueous solution, 97.3g chloroacetic acid was dissolved in 180.0g water to obtain chloroacetic acid aqueous solution; sodium hydroxide aqueous solution was added dropwise in chloroacetic acid aqueous solution to obtain sodium chloroacetic acid aqueous solution . The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com