Heat resisting coating and preparation method thereof

A technology of heat-resistant coatings and raw materials, applied in the field of coatings, can solve the problems of not too high dosage of monofunctional reactive diluent, limited dosage, low heat resistance, etc., to improve UV protection performance and stability, and reduce production costs , Improve the effect of adhesion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

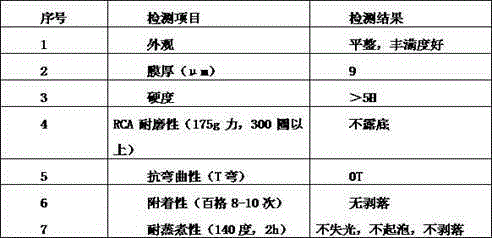

Image

Examples

Embodiment 1

[0017] The invention relates to a heat-resistant coating, which is made of the following raw materials in parts by weight: 1.5 parts of sodium dodecylbenzenesulfonate, 3.2 parts of sodium dibutylnaphthalene sulfonate, and 1.5 parts of barium 2-ethylhexanoate , 8.5 parts of aralkylphenol polyoxyethylene ether formaldehyde condensate, 2.5 parts of polyvinyl alcohol as thickener, 2.3 parts of borated oleamide, 4.5 parts of water, 3.4 parts of diethanolamine maleic anhydride complex ester, preservative namely sorbic acid 0.07 parts of acid.

[0018] The preparation method of above-mentioned heat-resistant paint, comprises the following steps:

[0019] 1) According to the above component distribution ratio, pour sodium dodecylbenzenesulfonate and sodium dibutylnaphthalenesulfonate into a container with a stirring device, add water filtered through bamboo charcoal, stir at 600r / min at a low speed for 40min, and mix Uniform;

[0020] 2) After standing still for 30 minutes, put bari...

Embodiment 2

[0024] The invention relates to a heat-resistant coating, which is made of the following raw materials in parts by weight: 3 parts of sodium dodecylbenzenesulfonate, 5.5 parts of sodium dibutylnaphthalene sulfonate, and 2 parts of barium 2-ethylhexanoate , 10.6 parts of aralkylphenol polyoxyethylene ether formaldehyde condensate, 3.4 parts of polyvinyl alcohol as thickener, 3.5 parts of borated oleamide, 7 parts of water, 5.6 parts of diethanolamine maleic anhydride complex ester, and preservative namely sorbic acid 0.12 parts of acid.

[0025] The preparation method of above-mentioned heat-resistant paint, comprises the following steps:

[0026] 1) According to the above component distribution ratio, pour sodium dodecylbenzenesulfonate and sodium dibutylnaphthalenesulfonate into a container with a stirring device, add water filtered by bamboo charcoal, stir at a low speed of 600r / min for 45min, and mix Uniform;

[0027] 2) After standing still for 35 minutes, put barium 2-e...

Embodiment 3

[0031] The invention relates to a heat-resistant coating, which is made of the following raw materials in parts by weight: 2.2 parts of sodium dodecylbenzenesulfonate, 4.5 parts of sodium dibutylnaphthalene sulfonate, and 1.7 parts of barium 2-ethylhexanoate , 9.6 parts of aralkylphenol polyoxyethylene ether formaldehyde condensate, 2.9 parts of polyvinyl alcohol as thickener, 3.1 parts of borated oleamide, 6.2 parts of water, 4.6 parts of diethanolamine maleic anhydride complex ester, and preservative namely sorbic acid Acid 0.09 parts.

[0032] The preparation method of above-mentioned heat-resistant paint, comprises the following steps:

[0033] 1) According to the above component distribution ratio, pour sodium dodecylbenzenesulfonate and sodium dibutylnaphthalenesulfonate into a container with a stirring device, add water filtered through bamboo charcoal, stir at 600r / min at a low speed for 50min, and mix Uniform;

[0034] 2) After standing still for 40 minutes, put bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com