Preparing method of titanium-based material surface composite antibacterial coating

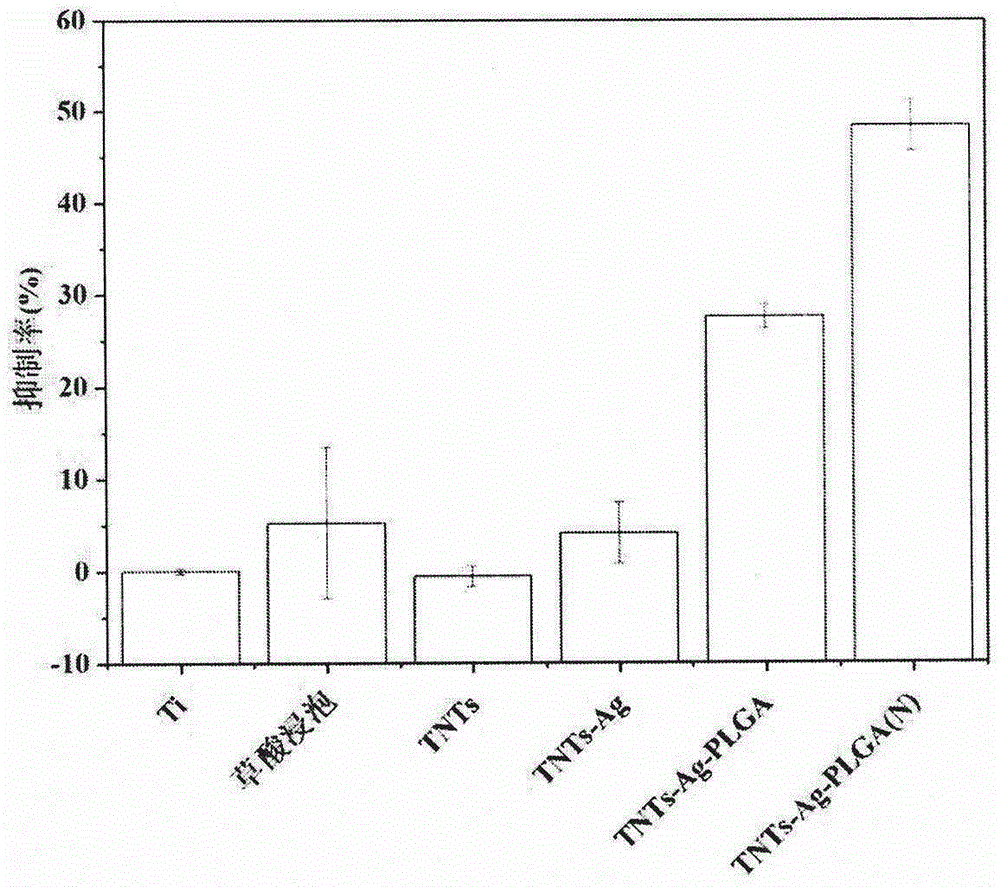

A surface composite, titanium-based technology, applied in the direction of metal material coating process, coating, superimposed layer plating, etc., to achieve good repeatability, improve effectiveness, and promote dissociation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] (1) Surface pretreatment of titanium sheet: polish the surface of titanium sheet with sandpaper until it is bright and without obvious scratches, soak the polished titanium sheet material in 30% NaOH solution, ultrasonicate for 30min, and then rinse the titanium sheet with ultrapure water After rinsing, blow dry, place the titanium piece in 10% oxalic acid solution and boil for 1 hour, take out the titanium piece and wash it with ultrapure water.

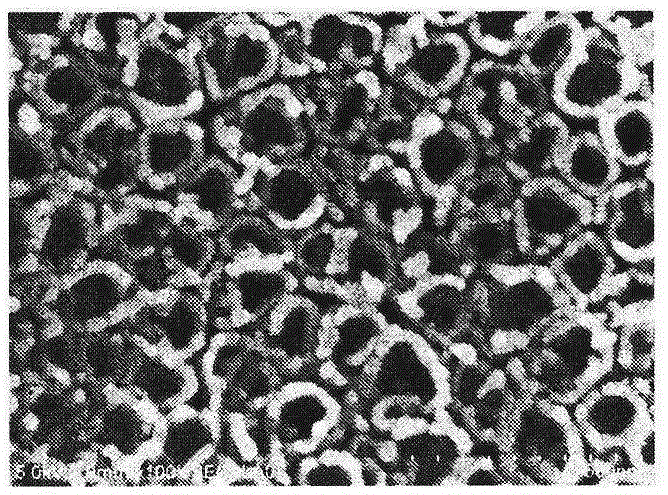

[0018] (2) Preparation of TNTs on the surface of the titanium sheet: the titanium sheet pretreated in step (1) is placed in an electrochemical anodizing device, the titanium sheet is used as the anode, the graphite is the cathode, and the electrolyte is an aqueous solution containing 1% HF. The distance between the electrodes is 6 cm, oxidized at a constant potential of 40 V for 20 min, and then the titanium sheet is taken out and placed in a muffle furnace, and anatase TNTs are produced by heat treatment at 500 °C for 1 h.

...

Embodiment 2

[0023] (1) Titanium sheet surface pretreatment: Take the pure titanium sample surface and polish it with sandpaper until it is bright and without obvious scratches, soak the polished titanium sheet material in 40% NaOH solution, ultrasonic for 20min, and then rinse with ultrapure water After the titanium sheet was rinsed, it was blown dry, and then the titanium sheet was placed in 10% oxalic acid solution and boiled for 1 hour, and the titanium sheet was taken out and cleaned with ultrapure water.

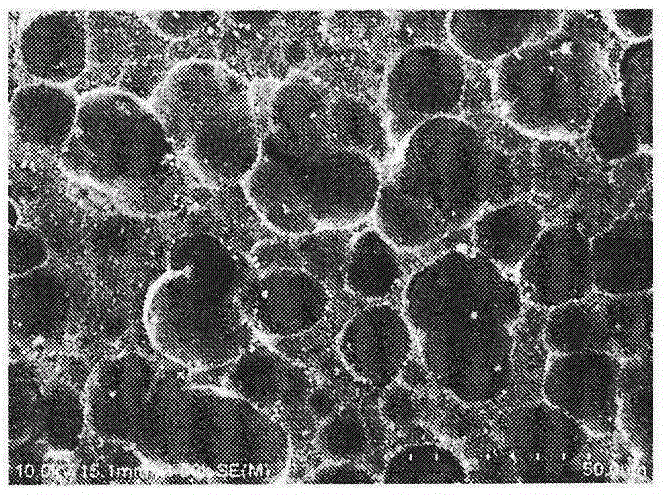

[0024] (2) Preparation of TNTs on the surface of titanium-based materials: place the pretreated titanium sheet in an electrochemical anodizing device, use the titanium sheet as the anode, graphite as the cathode, and the electrolyte contains 2% NaF, 85% ethylene glycol and 13 % water; the distance between the cathode and anode electrodes is 10cm, oxidize at a constant potential of 40V for 20min, then take out the titanium sheet and place it in a muffle furnace, heat treatment at 500...

Embodiment 3

[0028] Steps 1, 3, and 4 of this example are the same as those of Example 2, except that NH 4 F is an oxidizing agent, and the specific steps include: placing the pretreated titanium sheet in an electrochemical anodizing device, using the titanium sheet as the anode, graphite as the cathode, and the electrolyte containing 5% NH 4 F, 85% ethylene glycol and 10% water; the distance between the cathode and anode electrodes is 6cm, oxidized at a constant potential of 40V for 20min; then take out the titanium sheet and place it in a muffle furnace, heat treatment at 500°C for 2h to make a sharp Titanite-type TNTs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com