Component with over-voltage over-current protective effect and manufacturing process of the same

A technology of overvoltage and overcurrent protection and manufacturing process, which is applied in the direction of overvoltage protection resistors, electrical components, varistors, etc., can solve the problems of large accidents and slow protection, reduce costs, save energy consumption, avoid The effect of overcurrent fire problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] An overvoltage and overcurrent protection component and its manufacturing process, including varistor and PPTC electrode slurry, the composition and steps are as follows:

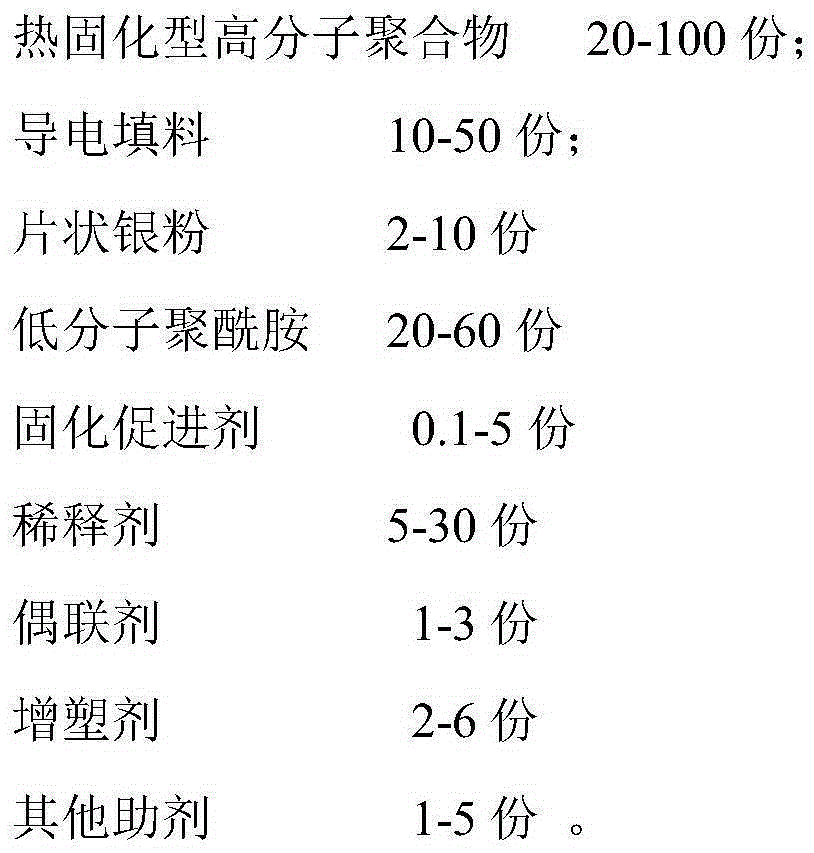

[0032] Slurry composition is in the present embodiment:

[0033] Liquid epoxy resin E-51, the number of parts by mass is 100 parts;

[0034] Conductive filler carbon fiber, 20 parts;

[0035] Flake silver powder, 5 parts;

[0036] Low-molecular-weight polyamide, content 50 parts;

[0037] Curing accelerator 2 ethyl-4 methyl imidazole (2E4MZ), 2 parts;

[0038] Thinner polypropylene glycol diglycidyl ether, 10 parts,

[0039] Coupling agent KH550, 3 parts,

[0040] Flame retardant aluminum hydroxide, 4 parts,

[0041] Antioxidant DOPO, 1 serving

[0042] The process of combining the above-mentioned PPTC electrode slurry with the piezoresistor to make a circuit protection component includes the following steps:

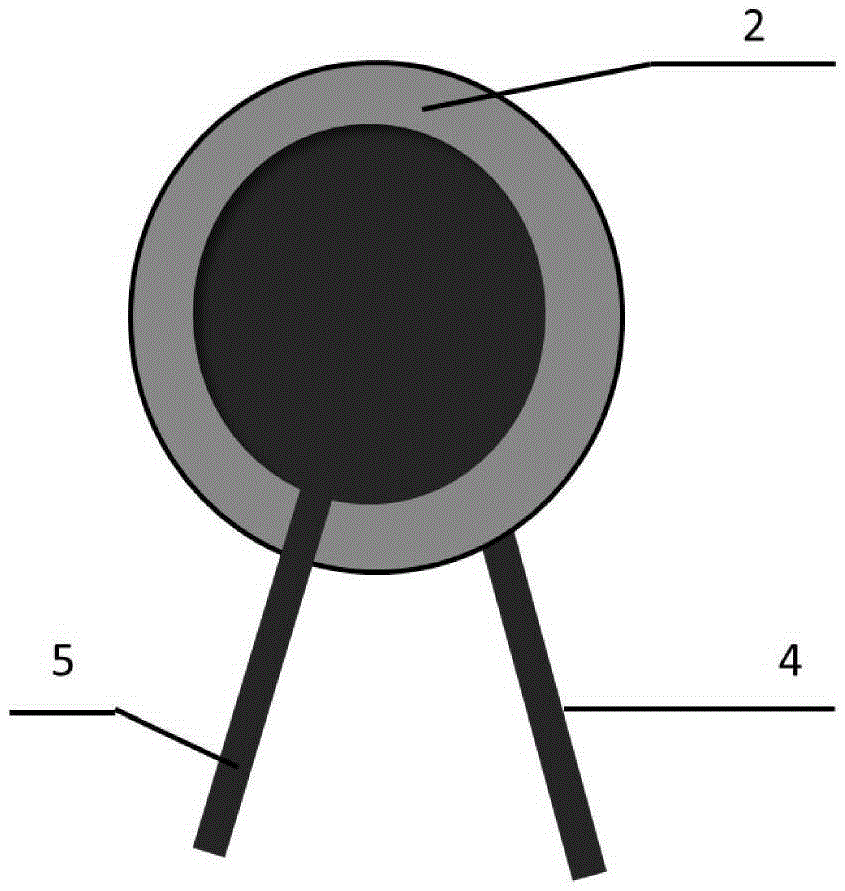

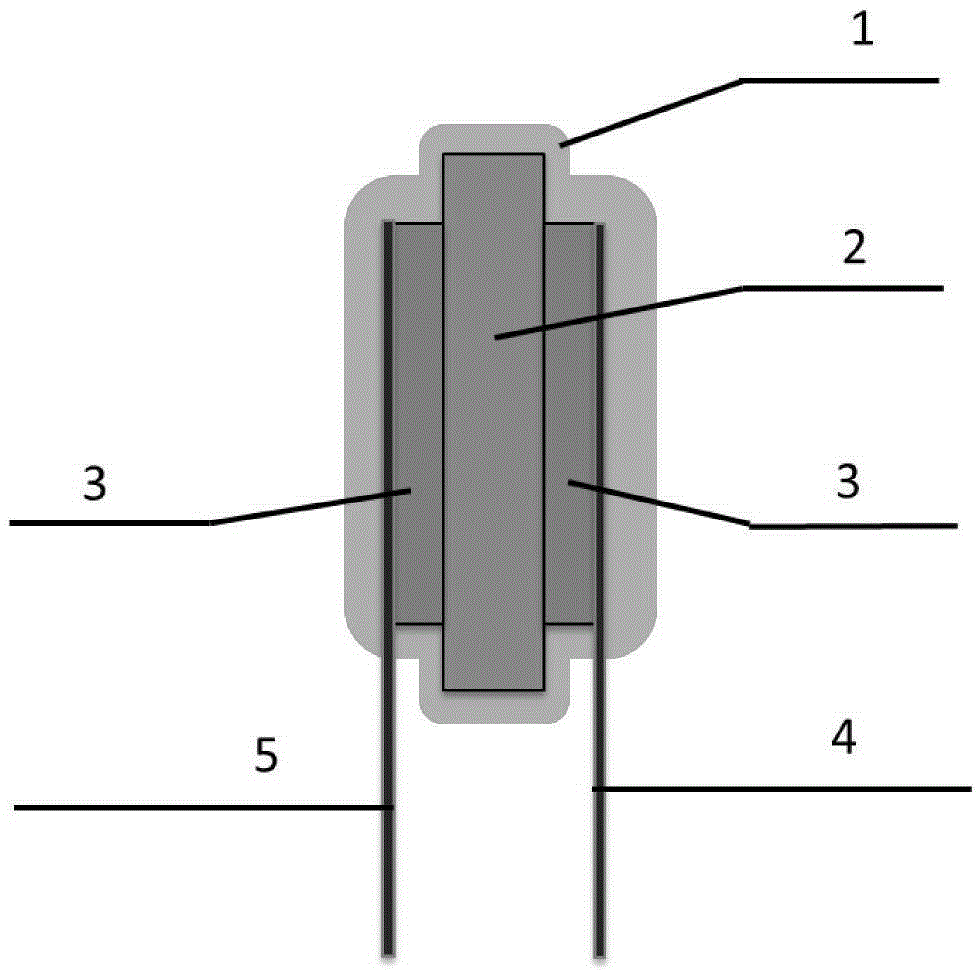

[0043] (1) Clean the general-purpose zinc oxide varistor sheet (model: diameter an...

Embodiment 2

[0049] An overvoltage and overcurrent protection component and its manufacturing process, including varistor and PPTC electrode slurry, the composition and steps are as follows:

[0050] In this embodiment, the slurry components are mainly

[0051] Polyurethane acrylate oligomer (PUA) 50 parts

[0052] Mixture of methyl methacrylate 50 parts

[0053] Conductive particle carbon fiber, the content is 20 parts;

[0054] Flake silver powder, 5 parts;

[0055] Photoinitiator benzoin butyl ether, 3 parts;

[0056]Thinner Dioctyl phthalate (DOP), 10 parts,

[0057] Coupling agent KH550, 3 parts;

[0058] Flame retardant aluminum hydroxide, 4 parts,

[0059] Antioxidant DOPO, 1 serving

[0060] The process of combining the above-mentioned PPTC electrode slurry with the piezoresistor to make a circuit protection component includes the following steps:

[0061] (1) Clean the general-purpose zinc oxide varistor sheet (model: diameter and thickness Φ14 / 1.8mm, varistor voltage V1mA...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com