Preparation method for polyallylamine-silicon oxide hybrid microcapsule with nano-scale capsule wall thickness

A polyallylamine and capsule wall thickness technology, which is applied in the preparation of microspheres, microcapsule preparations and other directions, can solve the problems of large mass transfer resistance, the wall thickness structure of hybrid microcapsules, etc. Simple and easy process, mild preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Step 1, preparing a calcium chloride solution with a concentration of 0.3M; preparing a sodium carbonate solution with an equimolar concentration to the calcium chloride solution; at a speed of 800r / min, pour the sodium carbonate solution into an equal volume of calcium chloride solution rapidly , reacted for 30s, centrifuged at a speed of 3000r / min, removed the supernatant and washed with deionized water; repeated centrifugation-washing, until the supernatant was free of sodium ions and chloride ions, calcium carbonate microspheres (CaCO 3 Microspheres);

[0021] Step 2: prepare a sodium silicate solution with a concentration of 0.03M, adjust the pH of the solution to 7.0; prepare a polyallylamine solution with a concentration of 0.2mg / mL, adjust the pH of the solution to 7.0; prepare a concentration of 0.01M Phosphoric acid Salt buffer solution, adjusting the pH of the solution to be 7.0;

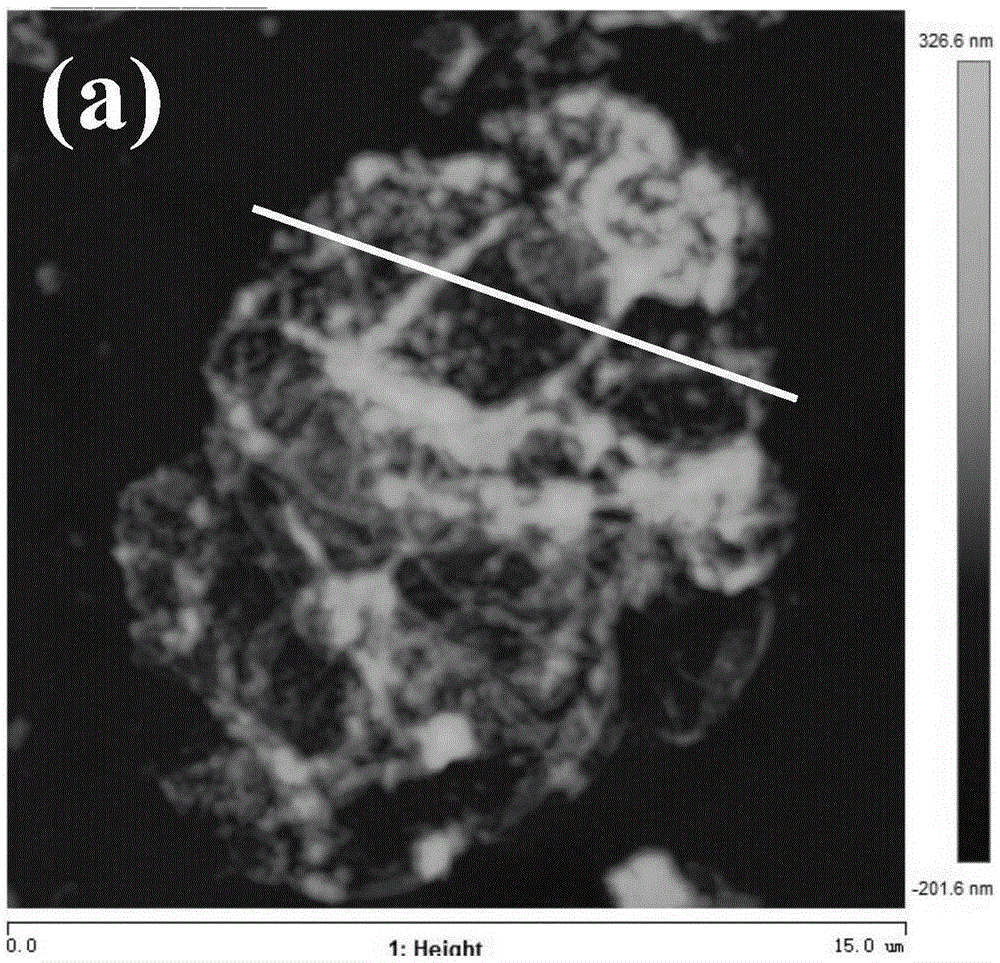

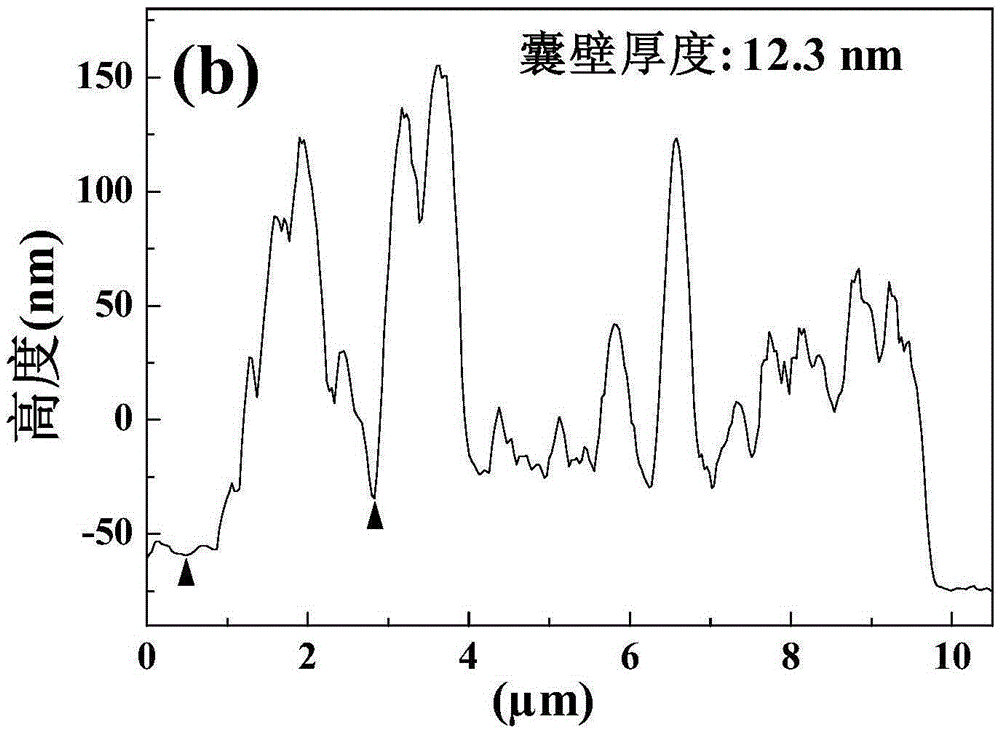

[0022] Step 3. According to the mass ratio of 40:1, uniformly mix the polyall...

Embodiment 2

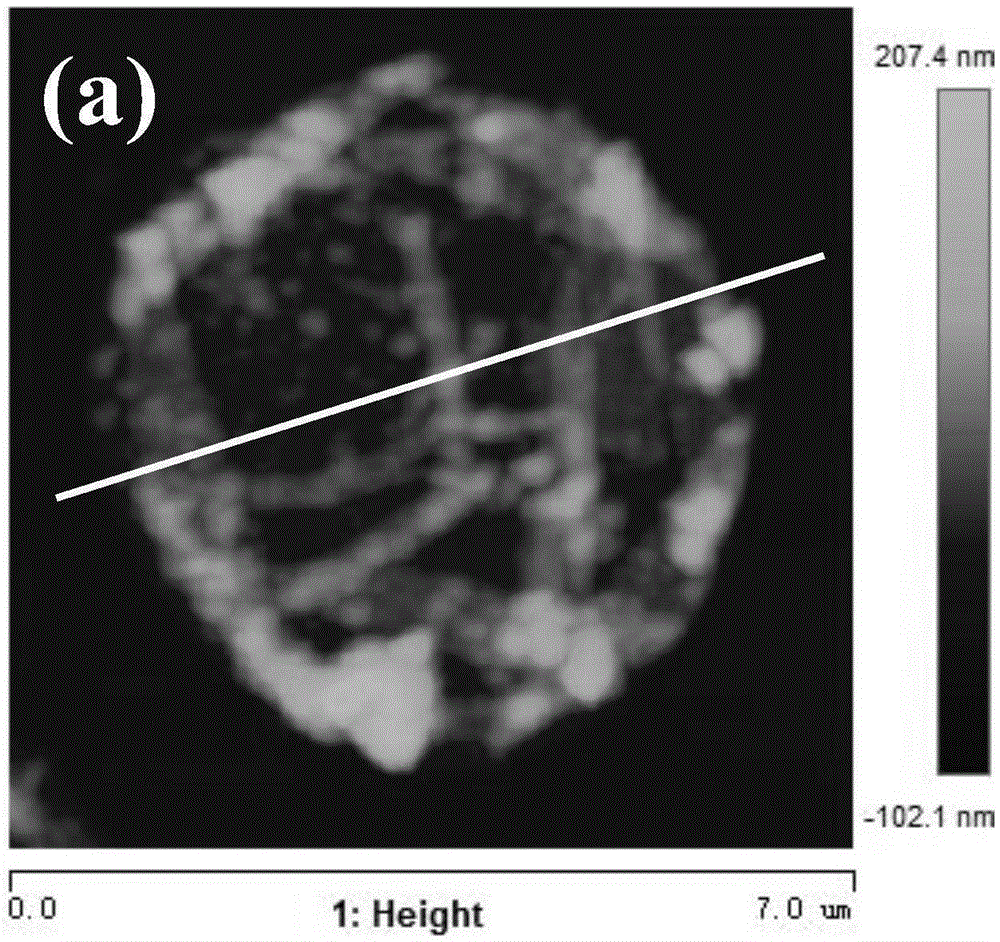

[0027] The steps of Example 2 are basically the same as those of Example 1, except that the concentration of the polyallylamine solution is 0.4 mg / mL, and a polyallylamine-silicon oxide hybrid with a wall thickness of 17.6 nm is finally obtained. Microcapsules. Figure 2(a) and Figure 2(b) are the AFM photographs of the polyallylamine-silicon oxide hybrid microcapsules prepared in Example 2 and the corresponding capsule wall thickness.

Embodiment 3

[0029] The steps of this Example 3 are basically the same as those of Example 1, except that the concentration of the polyallylamine solution is 0.8 mg / mL, and finally a polyallylamine-silicon oxide hybrid with a wall thickness of 17.2 nm is obtained. Microcapsules. Figure 3(a) and Figure 3(b) are the AFM photographs of the polyallylamine-silica hybrid microcapsules prepared in Example 3 and the corresponding capsule wall thickness.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com