Acrylpimaric acid diallyl ester and microwave-assisted synthesis method thereof

A technology of diallyl acrylopimarate and sodium acrylopimarate, which is applied in the product and preparation field of diallyl pimalate, can solve the problems that the hardness and other properties of the polymer product cannot meet the application requirements, the operation is cumbersome, and the reaction Long time and other problems, to achieve the effect of short reaction time, good purity and simple post-processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

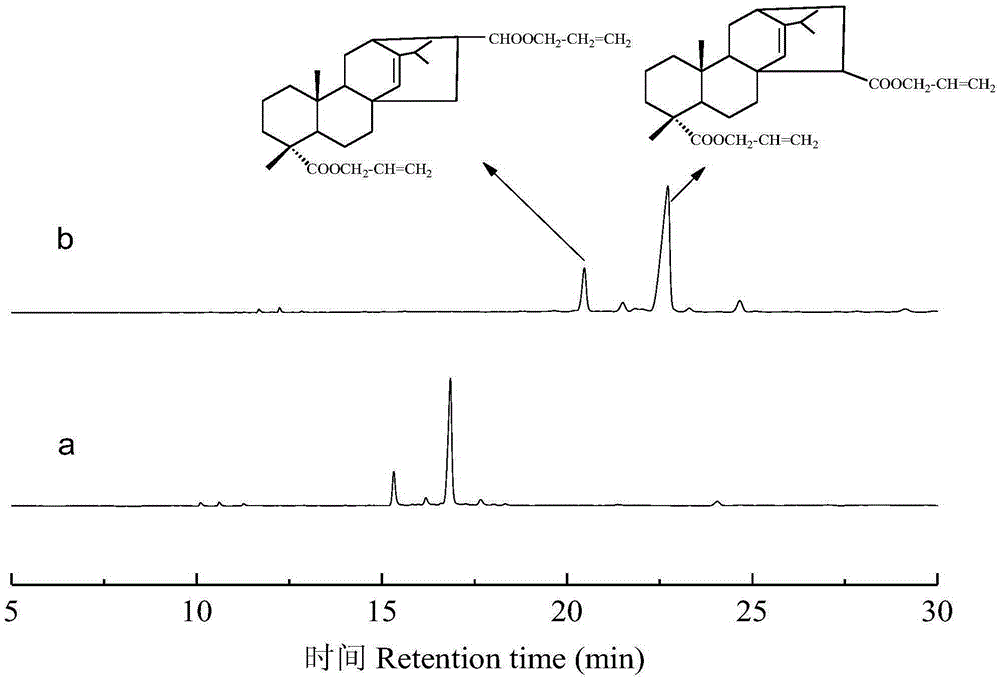

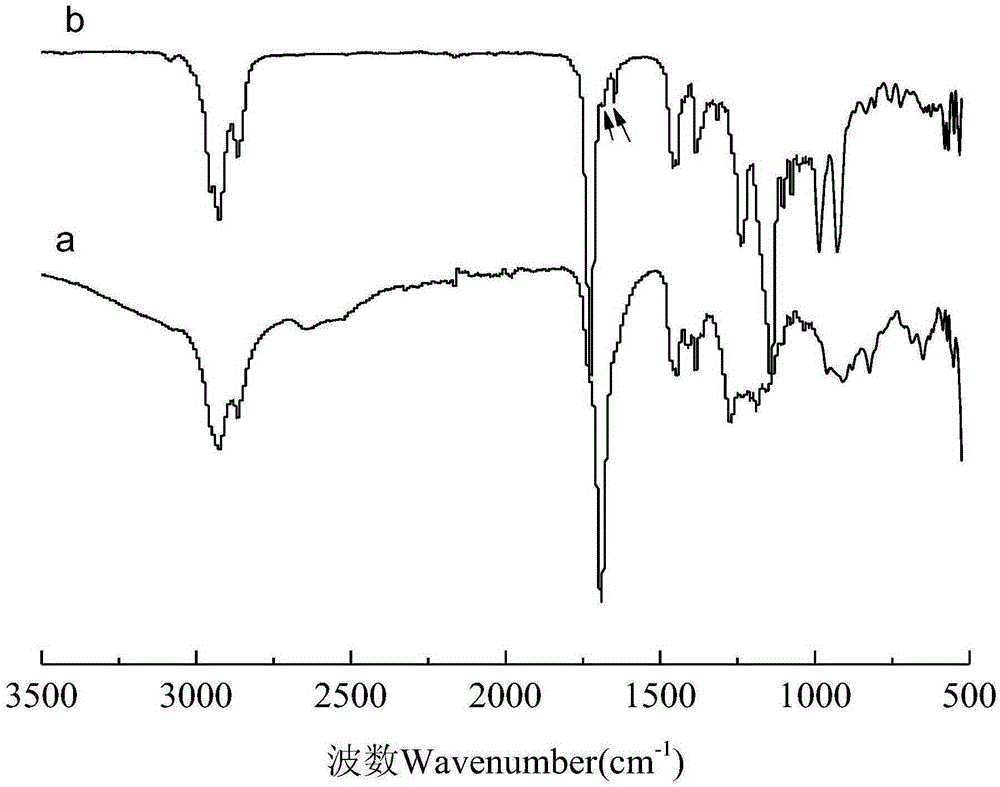

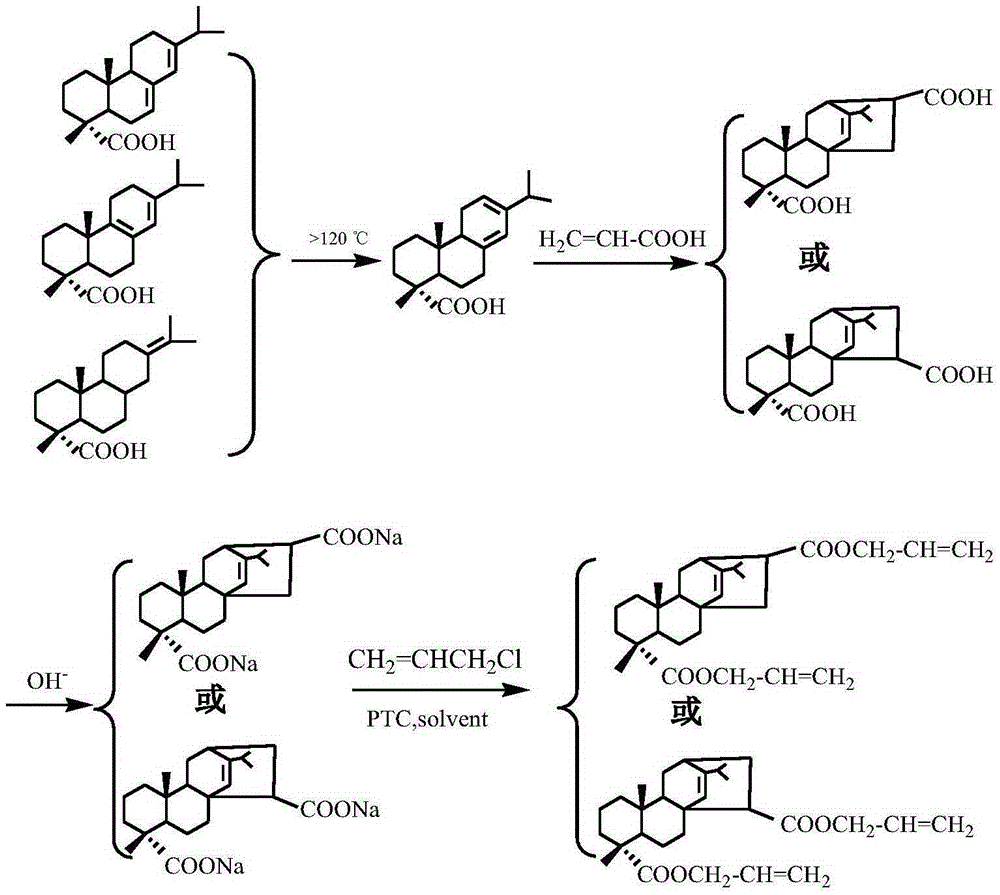

[0029] A kind of propylene pimarate diallyl product and microwave-assisted synthesis method thereof, its synthetic method comprises the steps: in the presence of propylene pimarate sodium and chloropropene in the presence of a quaternary ammonium salt catalyst and a polymerization inhibitor, with a strong polar organic solvent As a reaction medium, react for 10-120 minutes under the conditions of microwave power of 300-800W and microwave temperature of 40-90°C. After the reaction is complete, remove NaCl by filtration, add a certain amount of organic solvent for extraction, pour into a separatory funnel and shake well, let stand to separate layers, take the organic solvent layer, wash with distilled water until neutral, and remove the organic solvent by rotary evaporation to obtain a viscous liquid for the product. The product, propylenepimarate diallyl, is an isomer, and its main components are p-propylenepimarate diallyl and m-propylenepimarate diallyl, with a GC content exc...

Embodiment 1~16

[0046] In a 100mL three-necked microwave special flask, add allyl chloride and sodium propylene pimarate in a certain ratio of substances, add a certain amount of hexadecyltrimethylammonium bromide, and use 0.2% hydroquinone as a polymerization inhibitor. 25mL of N,N-dimethylformamide as a solvent, a certain volume of allyl chloride, magnetically stirred, condensed and refluxed, heated to a specific temperature to react for a period of time, filtered to remove the generated NaCl after the reaction, and the filtrate was extracted 3 times with n-hexane , 50mL each time, combined, washed with water until neutral, dried over anhydrous sodium sulfate, and removed n-hexane by rotary evaporation to obtain the product. Weigh the quality of the product obtained and calculate the yield. The results of Examples 1 to 16 are summarized in Table 1.

[0047] The influence of each factor of table 1 on the synthesis of diallyl propylene pimarate

[0048]

[0049]

Embodiment 17

[0051] In a 100mL three-necked microwave special flask, add allyl chloride and propylene pimarate at a ratio of 5:1, add 4% tetrabutylammonium bromide as a catalyst, and 0.3% phenothiazine as a polymerization inhibitor, 25mL N,N-dimethylformamide was used as a solvent, magnetically stirred, condensed and refluxed, heated to 55°C under the condition of microwave power of 400W and reacted for 90min. , 50 mL each time, combined, washed with water until neutral, dried over anhydrous sodium sulfate, and removed n-hexane by rotary evaporation to obtain the product with a yield of 72.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com