A kind of polyimide resin containing cyano group and its application in preparing copper-clad foil

A technology of polyimide resin and copper clad foil, which is applied in the field of copper clad foil, can solve the problems of low heat resistance and mechanical properties of copper clad foil, large difference in thermal expansion coefficient, small bonding ability, etc., and achieve good size Stability and mechanical properties, extended service life, easily controlled effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

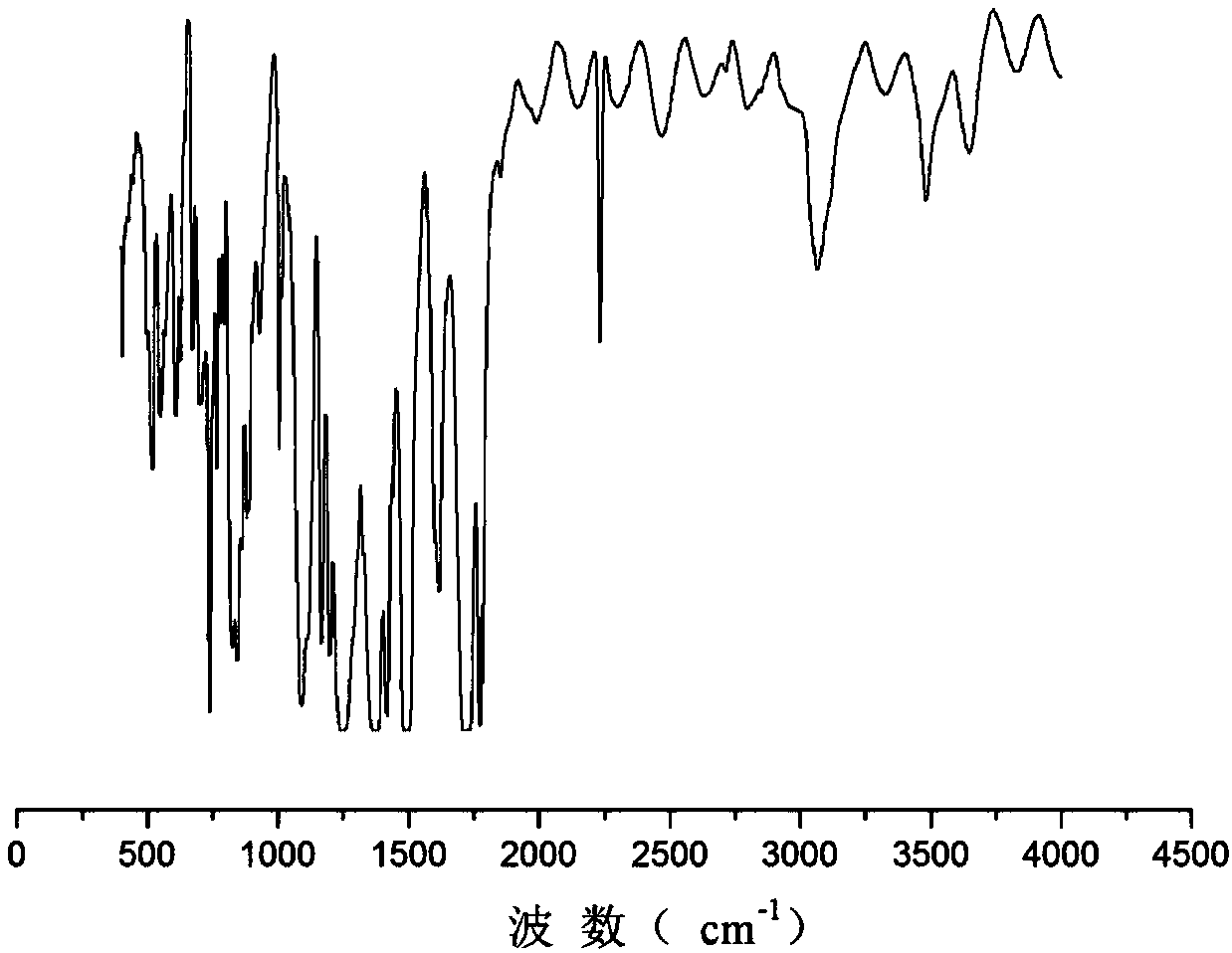

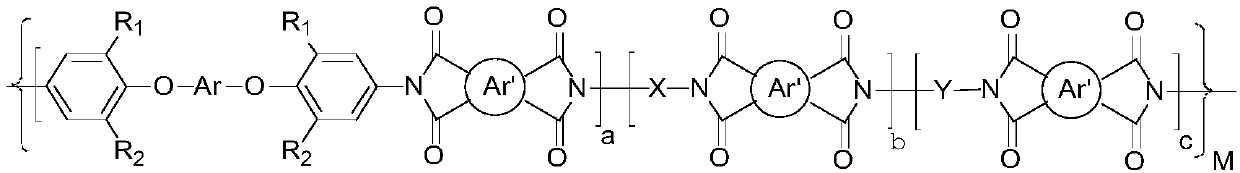

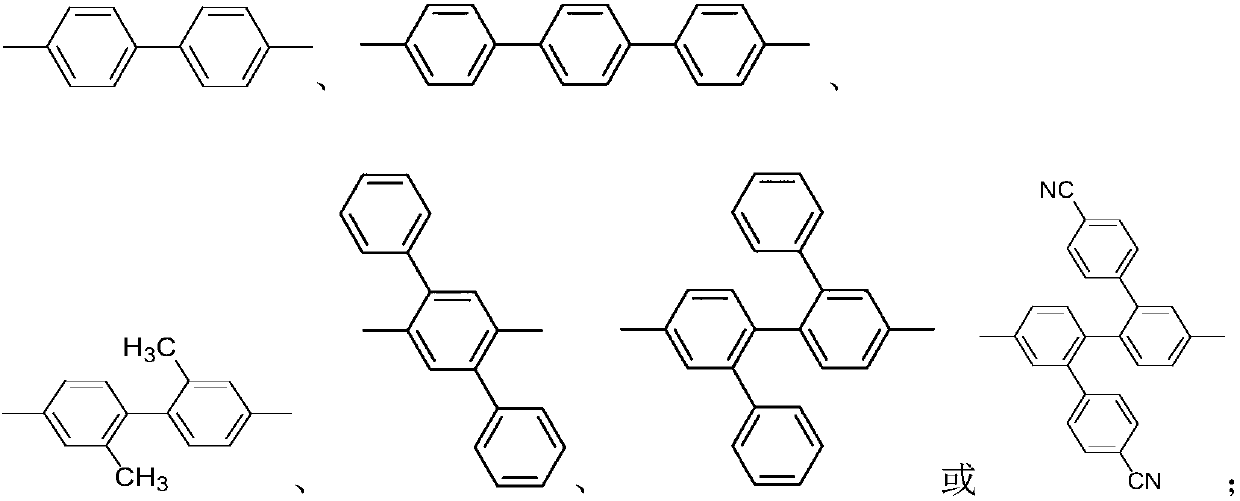

[0032] This example is to prepare a two-layer adhesive-free single-sided flexible copper-clad foil. In the general formula of the PI layer structure, when Ar is a biphenyl structure, X is a biphenyl structure, Y is a diphenyl ether structure, and the circled Ar' It is polyamic acid (PAA) and flexible copper clad foil material with 3,3',4,4'-biphenyltetraacid dianhydride structure, a=0.4, b=0.3, c=0.3.

[0033] 1) Pretreat the surface of the copper foil, first soak the copper foil in CH 2 Cl 2 , ultrasonic treatment for 0.5h to remove the surface grease of the copper foil, soak the soaked copper foil in 0.5mol / L dilute sulfuric acid for 4h to remove the oxide on the surface of the copper foil, wash 3 times with distilled water and 3 times with absolute ethanol, drying;

[0034] 2) Preparation of PAA solution

[0035]Weigh 0.8369g (2mmol) of 1,4-bis(4-amino-2cyanophenoxy)biphenyl, 0.2764g (1.5mmol) of benzidine, and 0.3004g (1.5mmol) of diphenyl ether diamine and dissolve it ...

Embodiment 2

[0041] Referring to Example 1, weigh 8.369 g (20 mmol) of 1,4-bis(4-amino-2 cyanophenoxy) biphenyl, 2.764 g (15 mmol) of benzidine, and 3.004 g (15 mmol) of diphenyl ether diamine Dissolve in 174mL of N,N-dimethylacetamide solution at room temperature (DMAC input according to 15% of the solid content of the system mass), stir for 20min until completely dissolved, add 3,3',4,4'- Biphenyltetraic dianhydride 14.711g (50mmol), keep the system in an anhydrous, clean and nitrogen environment, stir at 0°C for 48h, at this time the reaction bottle is a light yellow transparent viscous liquid, dilute and stir with DMAC for 4h After cleaning, drying, and standing at room temperature for 24 hours, a PAA solution with a concentration of 0.074g / ml was obtained.

[0042] The following steps follow the operation of Example 1 to obtain a two-layer adhesive-free single-sided flexible copper-clad foil. The performance parameters of the obtained flexible copper-clad foil and the performance para...

Embodiment 3

[0044] Referring to Example 1, 2) in the step, N,N-dimethylacetamide (DMAC) solution was replaced by N-methylpyrrolidone, and the amount added was 15.9mL (DMAC input according to 15% of the solid content of the system mass), The rest of the operations remain the same. When step 3) is performed, transfer the copper foil coated with PAA solution to a clean, dry and flat environment for drying according to the following procedures: 60°C for 24 hours, 80°C for 24 hours, and 120°C for 2 hours , dried at 150°C for 1 hour, and the rest of the operations were kept the same to obtain a two-layer flexible copper-clad foil with no adhesive on one side. Compared with Example 1, the linear expansion coefficient of the PI resin layer of the flexible copper-clad foil obtained was slightly increased. The CTE value is 33.24ppm / K.

[0045] The above-mentioned two-layer adhesive-free single-sided flexible copper-clad foil resin surface and the flat rolled copper foil with a thickness of 20 μm (e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com