High-mobility organic micromolecule-doped ternary solar cell

A solar cell and high mobility technology, applied in the field of organic thin film solar cells, can solve the problems of low hole transport and collection efficiency, and achieve the effects of improving short-circuit current density and filling factor, improving collection capacity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

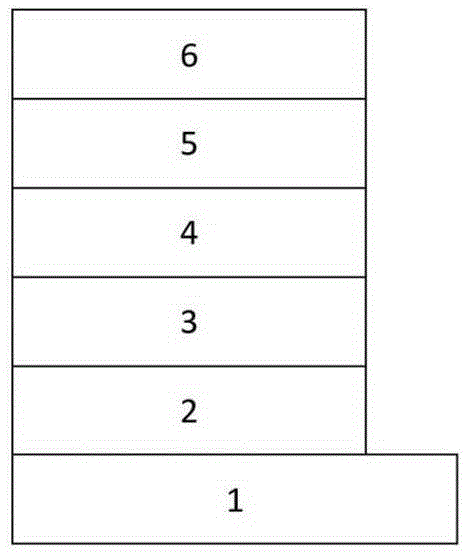

Method used

Image

Examples

Embodiment 1

[0025] Control group:

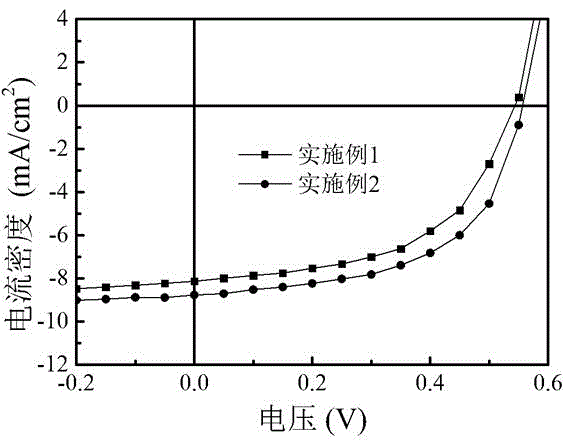

[0026] Clean the substrate composed of transparent substrate layer and transparent conductive cathode ITO with surface roughness less than 1nm, and dry it with nitrogen after cleaning; spin coating ZnO (5000rpm, 40s, 15nm) on the surface of transparent conductive cathode ITO to prepare cathode buffer Layer, and the formed film is thermally annealed (200℃, 60min); P3HT:PC is prepared by spin coating on the cathode buffer layer 61 BM (40%:60%) photoactive layer (1000rpm, 25s, 220nm), and thermal annealing (140℃, 5min); spin-coated PEDOT:PSS solution on the surface of the photoactive layer to prepare anode buffer layer (3000rpm, 60s) , 30nm), and thermal annealing (150℃, 5min); A metal anode Ag (100nm) was vapor-deposited on the anode buffer layer. Under standard test conditions (AM1.5, 100mW / cm 2 ), the measured open circuit voltage of the device (V OC ) = 0.56V, short-circuit current (J SC )=8.2mA / cm 2 , Fill factor (FF) = 0.53, photoelectric conversion ...

Embodiment 2

[0028] Clean the substrate composed of transparent substrate layer and transparent conductive cathode ITO with surface roughness less than 1nm, and dry it with nitrogen after cleaning; spin coating ZnO (5000rpm, 40s, 15nm) on the surface of transparent conductive cathode ITO to prepare cathode buffer Layer, and the formed film is thermally annealed (200℃, 60min); P3HT:PC is prepared by spin coating on the cathode buffer layer 61 BM:Tetracene (39.5%:60%:0.5%) photoactive layer (1000rpm, 25s, 220nm), and thermal annealing (140℃, 5min); spin-coating PEDOT:PSS solution on the surface of the photoactive layer to prepare anode buffer Layer (3000rpm, 60s, 30nm), and thermal annealing (150℃, 5min); metal anode Ag (100nm) is vapor-deposited on the anode buffer layer. Under standard test conditions (AM1.5, 100mW / cm 2 ), the measured open circuit voltage of the device (V OC ) = 0.55V, short-circuit current (J SC )=8.9mA / cm 2 , Fill factor (FF) = 0.57, photoelectric conversion efficiency...

Embodiment 3

[0030] Clean the substrate composed of transparent substrate layer and transparent conductive cathode ITO with surface roughness less than 1nm, and dry it with nitrogen after cleaning; spin coating ZnO (5000rpm, 40s, 15nm) on the surface of transparent conductive cathode ITO to prepare cathode buffer Layer, and the formed film is thermally annealed (200℃, 60min); P3HT:PC is prepared by spin coating on the cathode buffer layer 61 BM:Tetracene (39%:60%:1%) photoactive layer (1000rpm, 25s, 220nm), and thermal annealing (140℃, 5min); spin-coating PEDOT:PSS solution on the surface of the photoactive layer to prepare anode buffer Layer (3000rpm, 60s, 30nm), and thermal annealing (150℃, 5min); metal anode Ag (100nm) is vapor-deposited on the anode buffer layer. Under standard test conditions (AM1.5, 100mW / cm 2 ), the measured open circuit voltage of the device (V OC ) = 0.56V, short-circuit current (J SC )=9.1mA / cm 2 , Fill factor (FF) = 0.58, photoelectric conversion efficiency (PC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com