A method for recovering light hydrocarbons from petrochemical plant tail gas

A petrochemical plant, tail gas technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve problems such as large investment, low product purity, waste of resources, etc., achieve great economic value, improve separation coefficient, and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

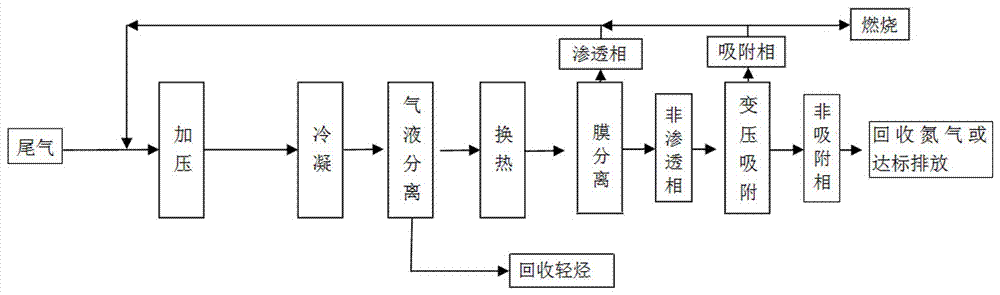

Method used

Image

Examples

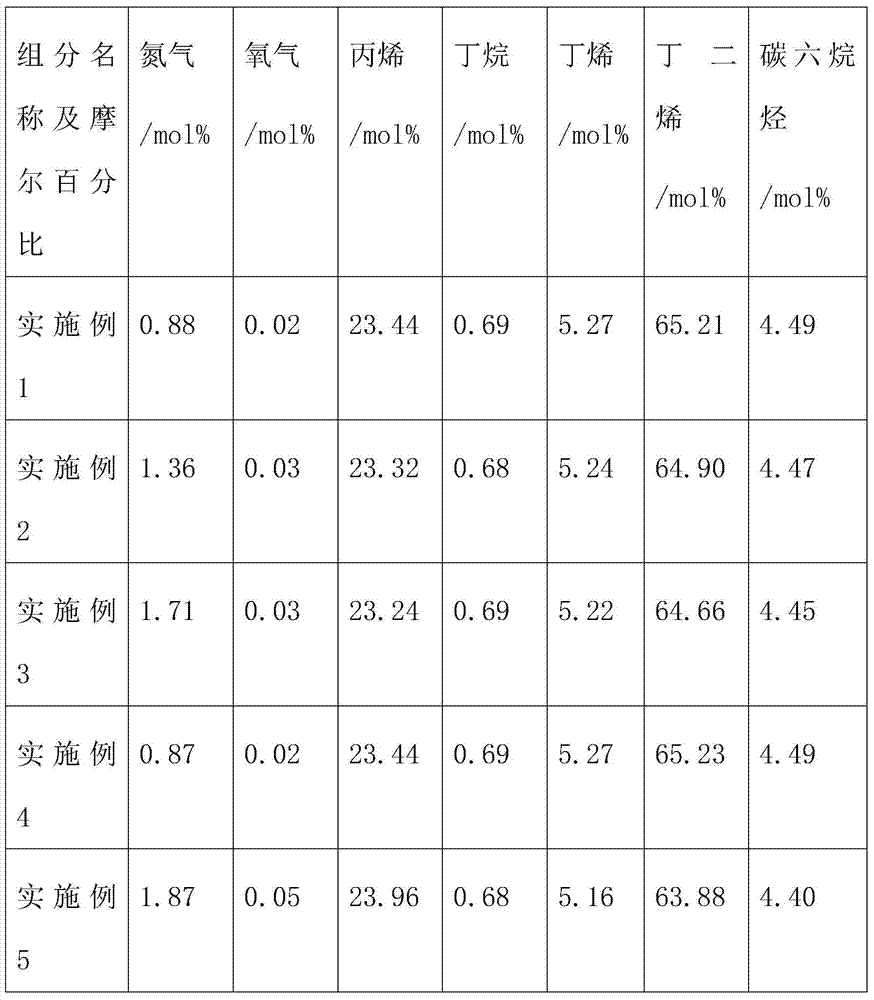

Embodiment 1

[0021] A method for recovering light hydrocarbons from petrochemical plant tail gas. The steps of the method are as follows: the petrochemical plant tail gas under normal temperature and pressure is pressurized to 0.5Mpa through a compressor, and the gas temperature at the gas outlet of the compressor is 40°C. The refrigerated water in the heater is condensed to -10°C, and the condensed tail gas of the petrochemical plant becomes a gas-liquid mixture. The gas-liquid mixture is separated into gas and liquid by a separation tank to recover liquid light hydrocarbons. Then raise the temperature of the gas in the gas-liquid separation tank to 5°C, and then enter the membrane separation device for separation. The membrane material used in the membrane separation device is silicone rubber, polyester, polyamide, polyimide, polysulfone, cellulose acetate Made of one or more of organic polymer materials such as polyether, etc., this kind of membrane material has a high separation coeffic...

Embodiment 2

[0023] A method for recovering light hydrocarbons from petrochemical plant tail gas. The steps of the method are as follows: the petrochemical plant tail gas under normal temperature and pressure is pressurized to 1.0Mpa through a compressor, and the gas temperature at the gas outlet of the compressor is 40°C. The chilled water in the heater is condensed to 4°C, and the condensed petrochemical plant tail gas becomes a gas-liquid mixture. The gas-liquid mixture is separated from the gas and liquid by the separation tank to recover liquid light hydrocarbons. Then the gas in the gas-liquid separation tank is heated up to 15°C, and then enters the membrane separation device for separation. The membrane material used in the membrane separation device is silicone rubber, polyester, polyamide, polyimide, polysulfone, cellulose acetate Made of one or more of organic polymer materials such as polyether, etc., this kind of membrane material has a high separation coefficient for nitrogen ...

Embodiment 3

[0025] A method for recovering light hydrocarbons from tail gas of a petrochemical plant. The steps of the method are as follows: the tail gas of a petrochemical plant under normal temperature and pressure is pressurized to 1.2Mpa through a compressor, and the gas temperature at the gas outlet of the compressor is 40°C. The chilled water in the heater is condensed to 0°C, and the condensed petrochemical plant tail gas becomes a gas-liquid mixture. The gas-liquid mixture is separated into gas and liquid by a separation tank to recover liquid light hydrocarbons. Then the gas in the gas-liquid separation tank is heated up to 12.5°C, and then enters the membrane separation device for separation. The membrane material used in the membrane separation device is silicone rubber, polyester, polyamide, polyimide, polysulfone, cellulose acetate Made of one or more of organic polymer materials such as polyether, etc., this kind of membrane material has a high separation coefficient for nit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com